Method and device for hot forming of medium-thickness plates under elastic preloading

A preloading and plate technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult to achieve medium-thick plate forming, and achieve the effects of large processing flexibility, reduced requirements, and reduced injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

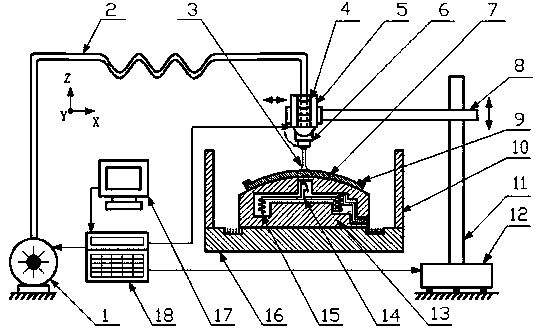

[0018] Example 1: High-pressure injection impact forming of aluminum alloy medium-thick plate with hot liquid medium under elastic preload.

[0019] The device includes a liquid delivery system, a workholding system, a moving system, a heating system and a control system. The liquid transmission system includes a high-pressure pump 1, a high-pressure pipe 2, an injection head 5, a high-pressure nozzle 6, and a high-pressure hot liquid medium 3; the moving system includes a cantilever beam 8, a column 11, and a base 12; the workpiece fixture system includes a medium-thick plate 7, a clamp 9. Baffle plate 10, pre-bending mold 13, workbench 16; heating system includes heater 4, temperature switch 14, resistance heating rod 15; control system includes computer 17, controller 18.

[0020] The medium-thick plate 7 to be formed is tightly attached to the surface of the pre-bending mold 13 under the action of the clamping force of the clamp 9 , and after obtaining a preliminary pre-de...

Embodiment 2

[0022] Example 2: High-pressure injection impact forming of hot liquid medium in medium-thick magnesium alloy plate under elastic preload.

[0023] The difference between this embodiment and embodiment 1 is that the medium-thick magnesium alloy plate is heated to 300-350°C, the temperature of the high-pressure hot liquid medium is heated to 250°C, and the injection pressure of the high-pressure hot liquid medium 3 is 20-40MPa. Others are the same as in Example 1.

Embodiment 3

[0024] Example 3: High-pressure injection impact forming of titanium alloy medium-thick plate with hot liquid medium under elastic preload.

[0025] The difference between this embodiment and embodiment 1 is that the titanium alloy medium-thick plate is heated to 700-920°C, the temperature of the high-pressure hot liquid medium is heated to 400°C, and the injection pressure of the high-pressure hot liquid medium 3 is 80-250MPa. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com