Bi-directional supporting system deformation monitoring and compensating device and construction method

A deformation monitoring and support system technology, applied in the direction of measuring devices, optical devices, excavation, etc., can solve problems such as difficulty in ensuring safe construction of deep and large foundation pits, difficulty in ensuring torque, and affecting the stress safety of steel support systems. Long side effect, avoid displacement error, ensure the effect of axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

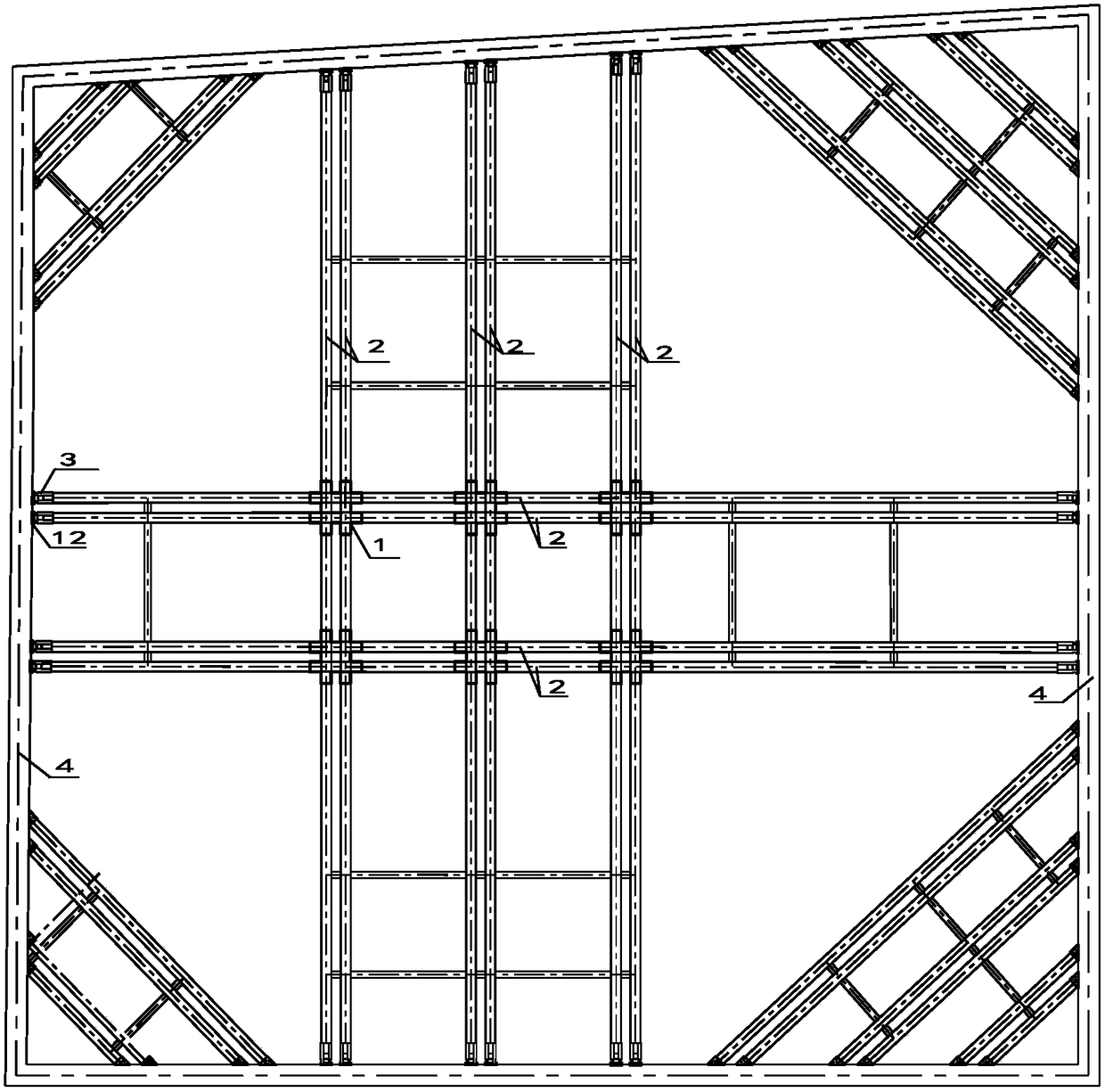

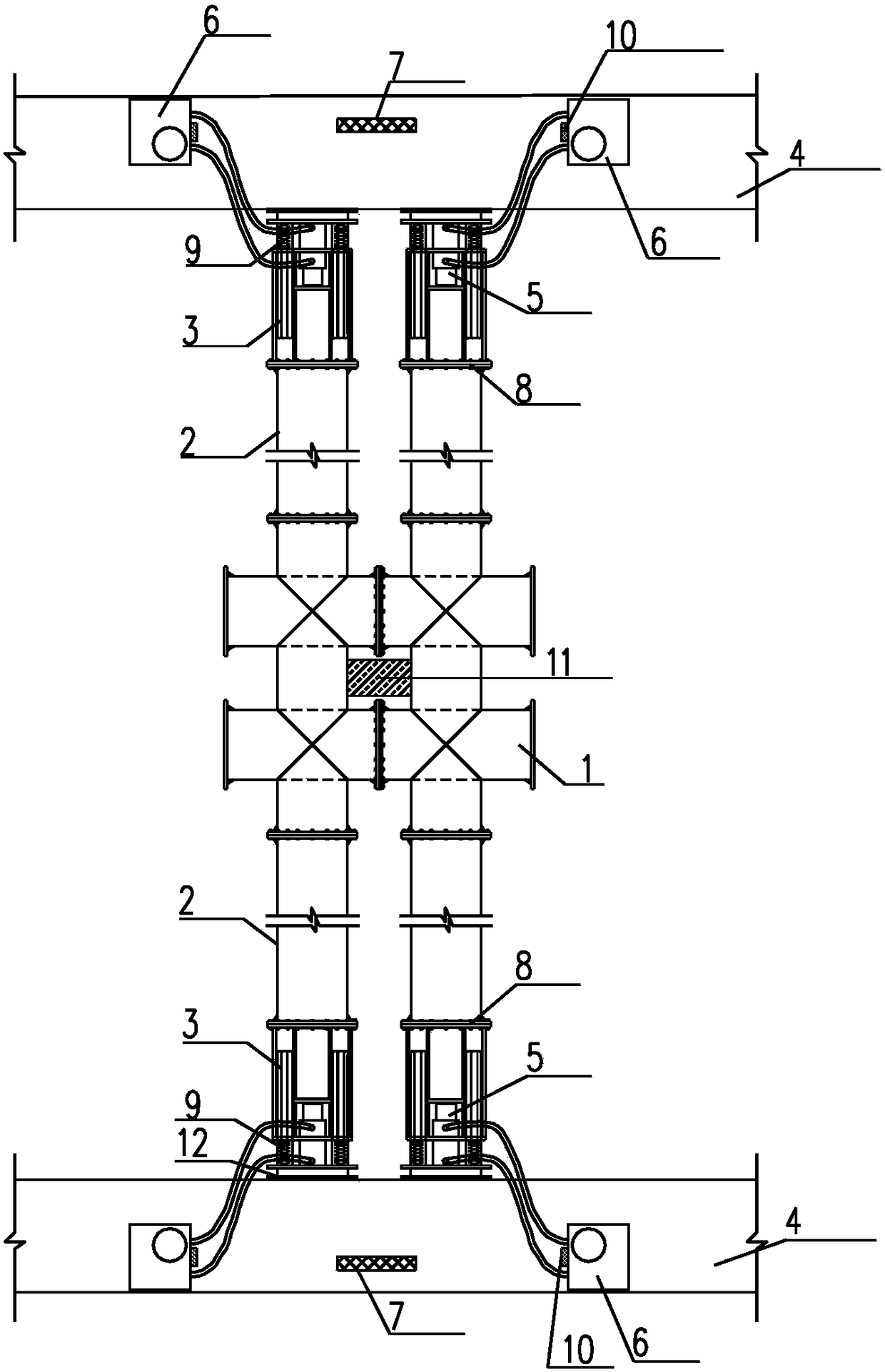

[0031] Combine below figure 1 and figure 2 The composition of the bidirectional support system deformation monitoring and compensating device of the present invention will be described in detail.

[0032] Such as figure 1 and figure 2 As shown, this embodiment discloses a two-way support system deformation monitoring and compensation device, including a cross joint 1, a steel support 2 and an active end 3, and the steel support 2 and the active end 3 are arranged symmetrically on both sides of the cross joint 1, and the steel support 2 It is composed of a number of steel support standard sections (not shown) connected end to end in sequence; one end of the active end 3 is fixedly connected to the steel support 2, and the other end of the active end 3 is connected to the purlin 4 of the foundation pit through the embedded part 12; it also includes The synchronous control device 11, the synchronous control device 11 is arranged on the cross joint 1, the synchronous control ...

Embodiment 2

[0038] Please continue to refer figure 1 and figure 2 , the present embodiment provides a construction method of a two-way support system deformation monitoring compensation device, the construction method includes the following steps:

[0039] Step 1. Excavate the earthwork of the foundation pit from the middle to both sides, and form opposite braces and diagonal braces in turn: During the excavation process of the foundation pit, excavate the earthwork in the middle of the foundation pit first to form the vertical (or horizontal) opposite braces in the middle. Brace, apply prestress to ensure that it bears force against the brace, and reduce the effect of the long side of the foundation pit; then excavate from the middle to both sides to form a horizontal (or vertical) brace of the foundation pit, and apply prestress; finally excavate the foundation The earthwork at the corner of the pit is formed to form a diagonal brace at the corner, and prestress is applied to ensure the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com