Spliced and assembled framework building structure and construction method thereof

A technology of frame building and connectors, which is applied in the direction of building components, building structures, buildings, etc., can solve problems affecting construction progress, docking difficulties, and waste of construction time, and achieve simplified assembly difficulty, low construction difficulty, and improved work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

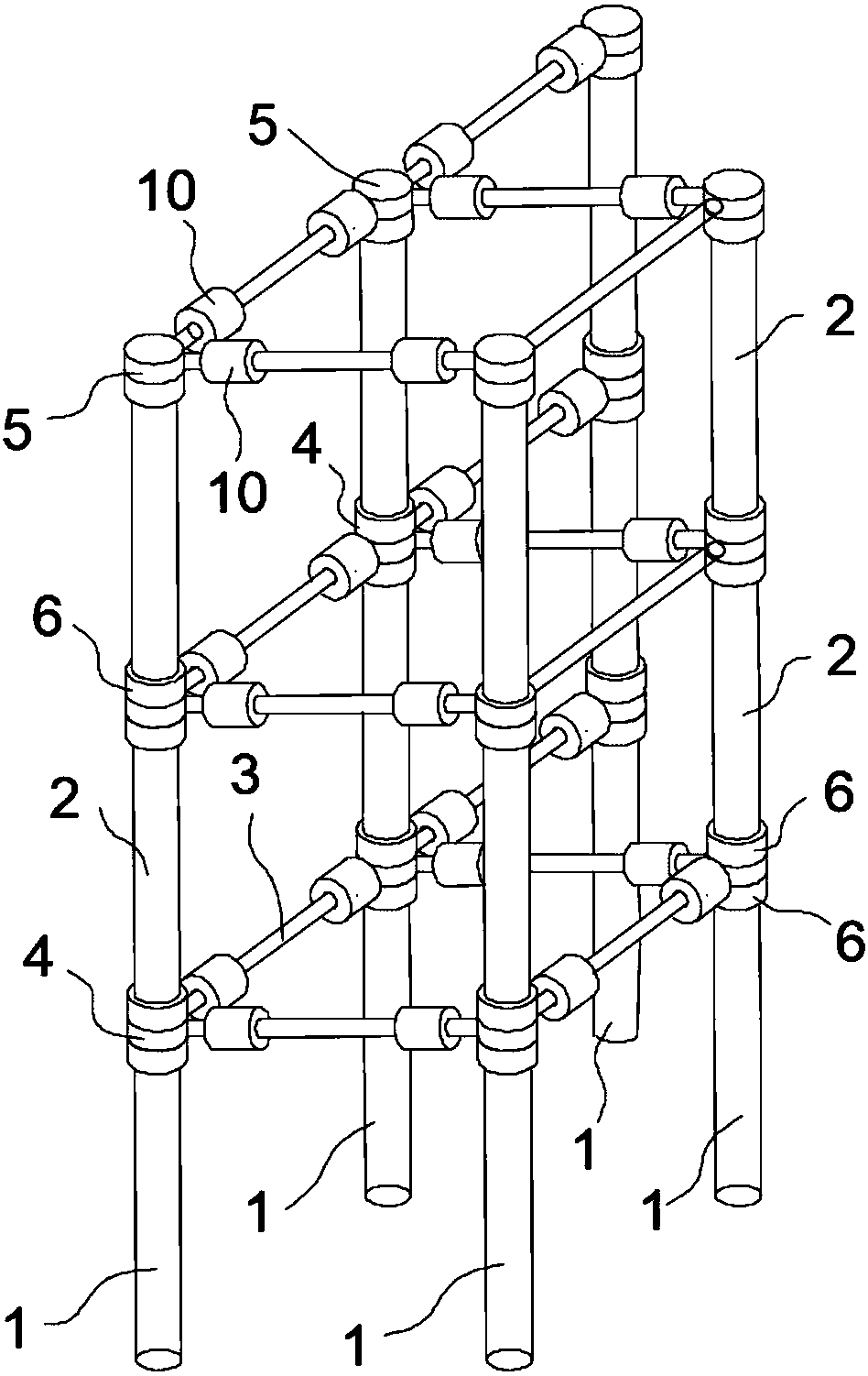

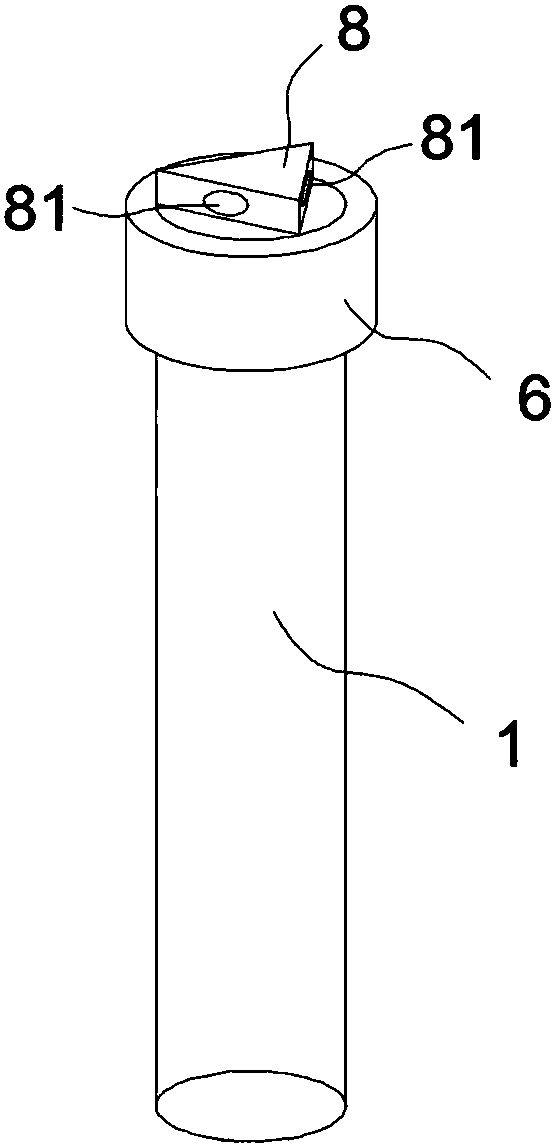

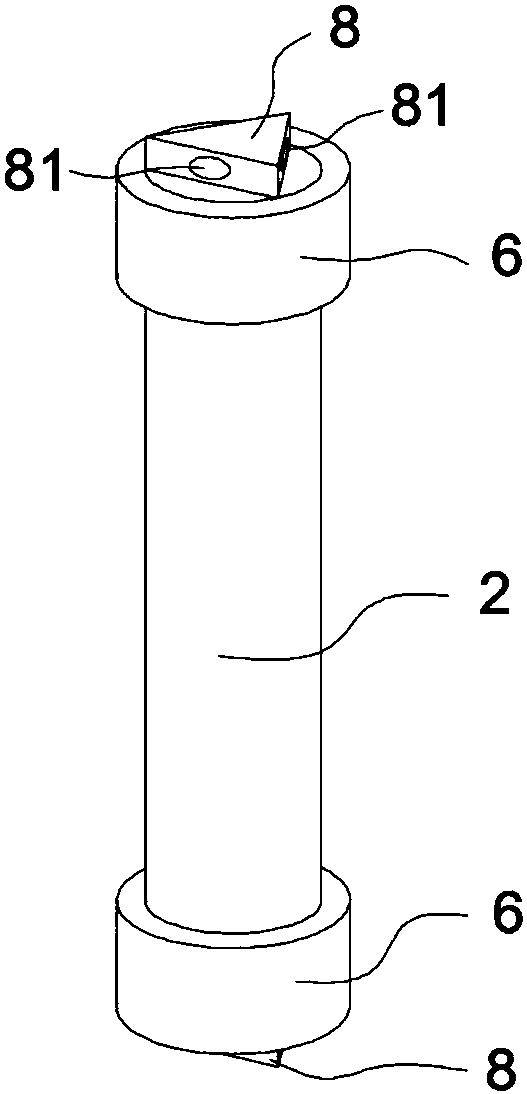

[0032] Such as Figure 1-4 As shown, a spliced and assembled frame building structure includes a bottom layer, a middle layer and a top layer. The bottom layer is provided with a number of columns 1, and the upper end of the column 1 is provided with a limit joint 6; the middle layer and the top layer are connected by a column 2, a connecting beam 3, and the middle The head 4 and the top connector 5 are spliced together; the upper and lower ends of the inter-column 2 are provided with a limit joint 6, which is fixed on the upright post 1 and the inter-column 2 through holes, and the material of the limit joint 6 is selected from composite engineering. Plastics, the strength and hardness of engineering plastics are now comparable to metals, and it has better practical effects, which can reduce the impact of thermal expansion and contraction on the joints between components, and it is difficult to make it through hole inlaying and fixing. The effect is good and meets the req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com