Test method for working resistance of loader test bench and front-end working part of loader

A technology of loaders and test benches, applied in the field of machinery, can solve the problems of low insertion speed control accuracy, unfavorable test results, and low reliability, and achieve the effects of widely simulating the scope of application, shortening the research cycle, and improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

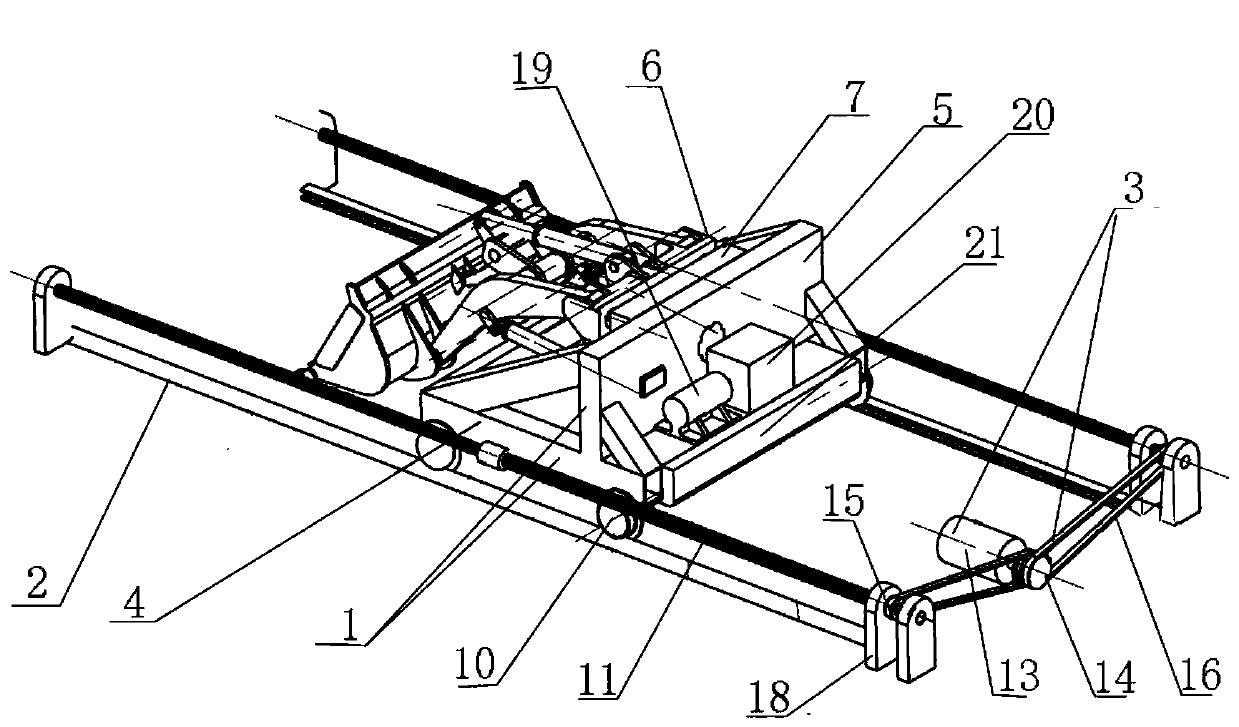

[0066] Such as Figure 1-4 Shown, the used device of the inventive method and the structure of test bench are as follows:

[0067] Including trolley 1, track 2, driving device 3;

[0068] The trolley 1 is installed on the track 2, and the driving device 3 is linked with the trolley 1 to drive the trolley 1 to move along the track;

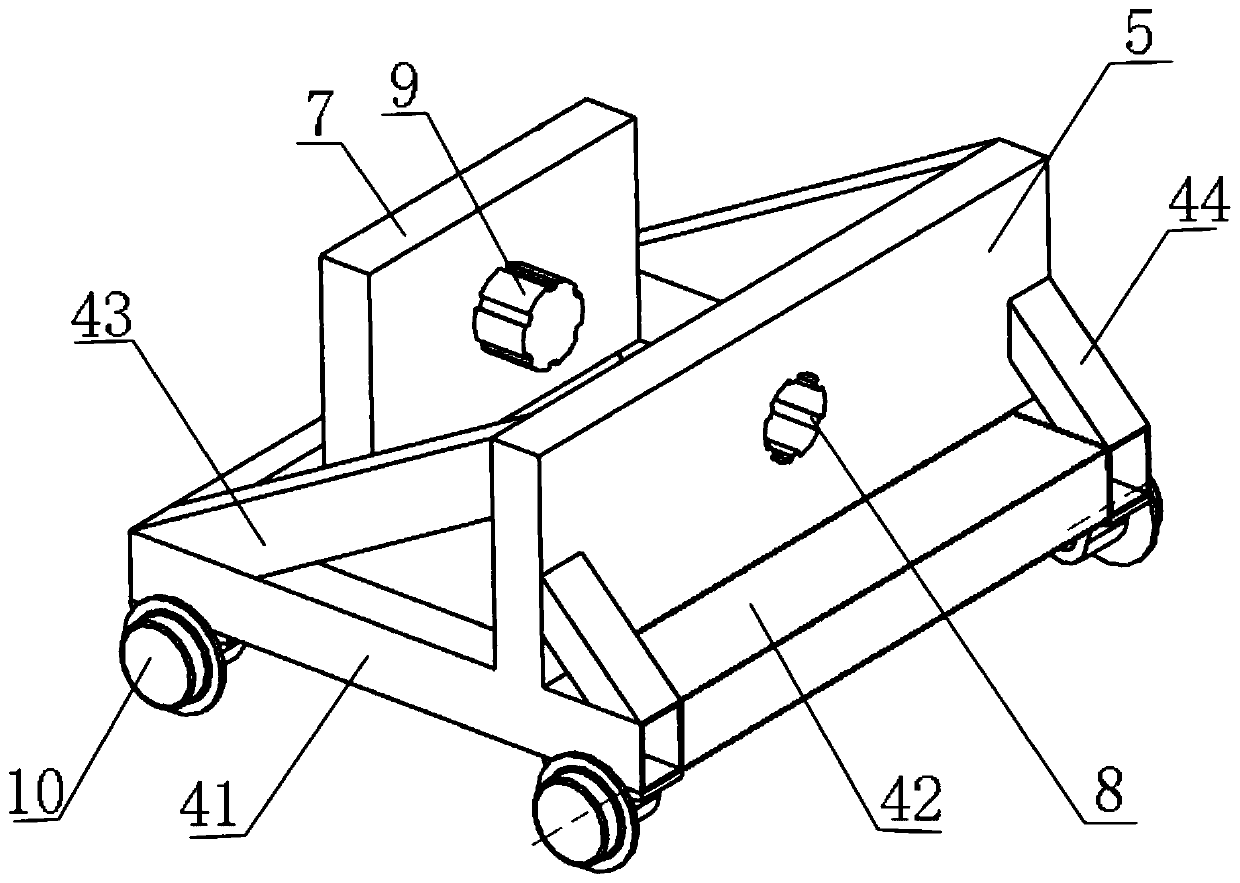

[0069] The trolley 1 includes a vehicle frame 4, a mounting plate 5, a hydraulic drive, a fixed plate 6, and a quick connecting plate 7; the vehicle frame 4 is installed on the track 2; the mounting plate 5 is vertically arranged on On the vehicle frame 4, an installation interface 8 is provided on it;

[0070] The front wall of the fixed plate 6 is provided with a mounting point for the front-end working parts of the loader; the front-end working parts of the loader are composed of a front-end working part, a boom, and a supporting hydraulic cylinder;

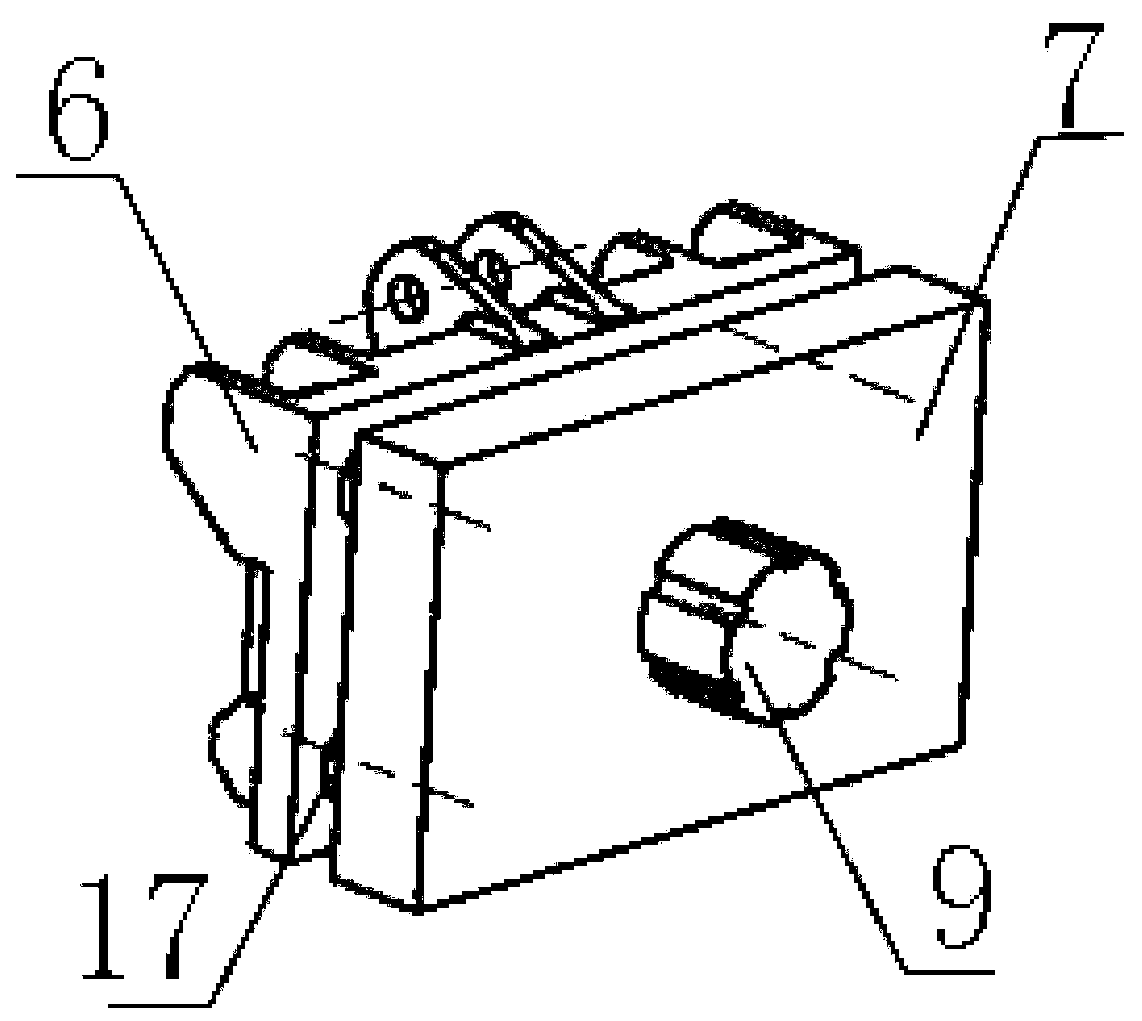

[0071] The rear wall of the fixed plate 6 is connected to the front wall of the fast connect...

Embodiment 2

[0082] The results of the operation resistance test of the front end of the loader are as follows:

[0083] A. Utilize the test bench with driving device, fixed plate 6 and quick connection plate 7 to set the experimental stockpile before the front end of the test bench;

[0084] B. Disassemble the loader to be tested to obtain the front-end working device; or directly assemble to obtain the front-end working device;

[0085] C. Install the front end working device on the fixed plate 6 to form the front end of the trolley;

[0086] D. Install the fixed plate 6 on the quick connecting plate 7 through the three-dimensional force sensor 17, the fixed plate 6 and the quick connecting plate (7) are parallel to each other, and then insert the quick connecting plate 7 on the mounting plate 5, so that the front end will work The device and the trolley are assembled into one;

[0087] E. Adjust the hydraulic drive device to control the front working part to reach the set height and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com