Pre-twisted wire breakage contact resistance experimental measuring method based on thermoelectric conversion

A contact resistance and thermoelectric conversion technology, which is applied in grounding resistance measurement, measurement device, measurement of electrical variables, etc., can solve the problems of voltage measurement equipment interference, inability to obtain AC contact resistance, current and voltage phase difference, etc., to achieve research and analysis errors. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

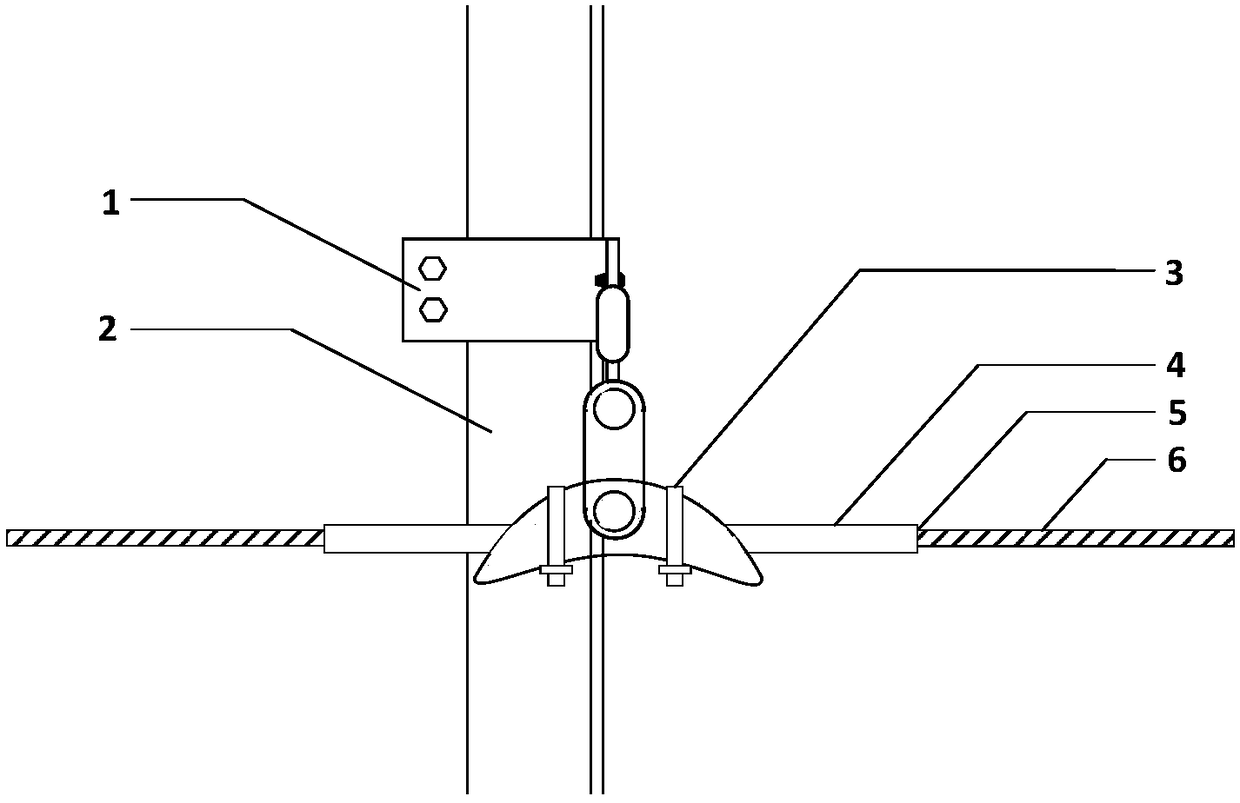

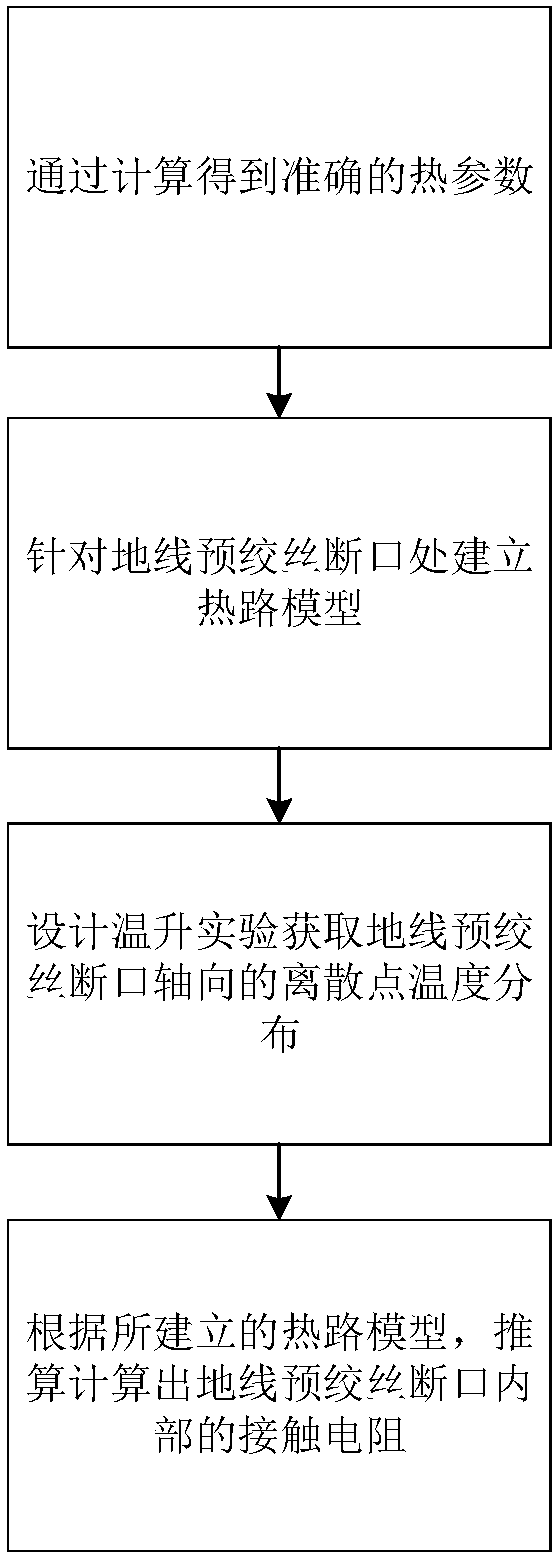

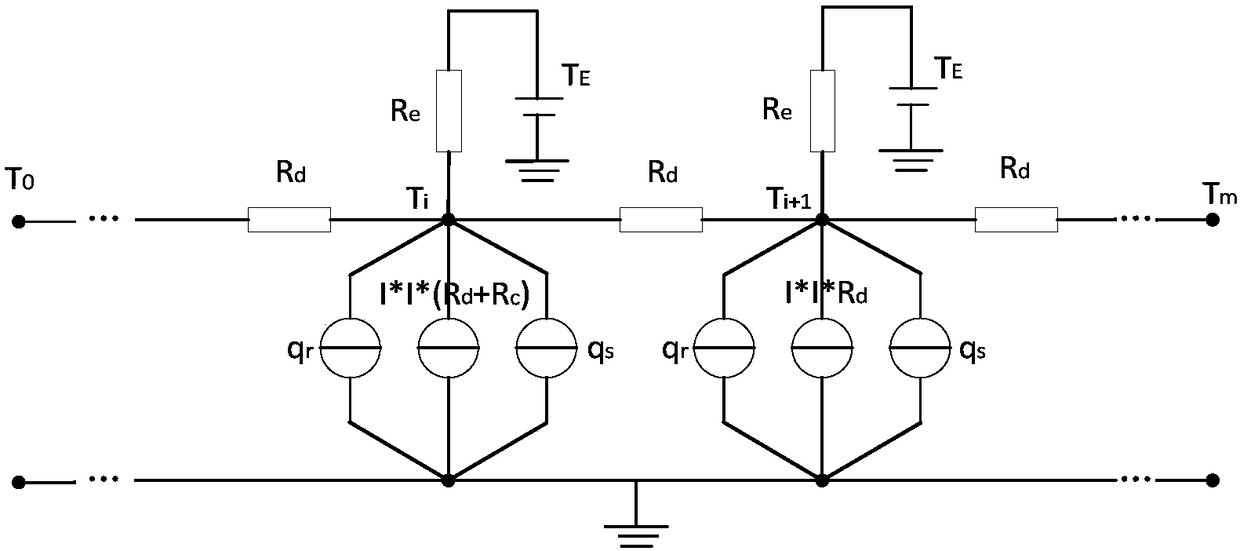

[0041] Such as figure 1 Shown is the structure diagram of the suspension string of the ground wire, including the tower fastener 1, the tower 2, the suspension clamp 3, the pre-twisted wire 4, the pre-twisted wire fracture 5, and the ground wire 6, in order to adjust the internal contact resistance of the pre-twisted wire fracture 5 Accurate measurement, this embodiment uses such as figure 2 Shown a kind of contact resistance experimental measurement method based on the pre-twisted wire fracture of thermoelectric conversion, this method comprises the following steps:

[0042] S1. Accurate thermal parameters are obtained through calculation;

[0043] There are many ways to calculate various thermal parameters (thermal conduction resistance, convection resistance, heat capacity, etc.) in the thermal circuit model, and the most basic method is to calculate directly through the following formula,

[0044] C = mc (1)

[0045] R d = l / (Sλ) (2)

[0046] R e =1 / (Ah c ) (3)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com