Visual guidance system and visual guidance method

A visual guidance and visual technology, applied in control/regulation systems, non-electric variable control, instruments, etc., can solve the problems of insufficient positioning accuracy, limitations, and large positioning deviations, and achieve the effect of improving the inherent positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Various embodiments of the present invention are described below with reference to the accompanying drawings. It should be understood that the embodiments are illustrative and not restrictive.

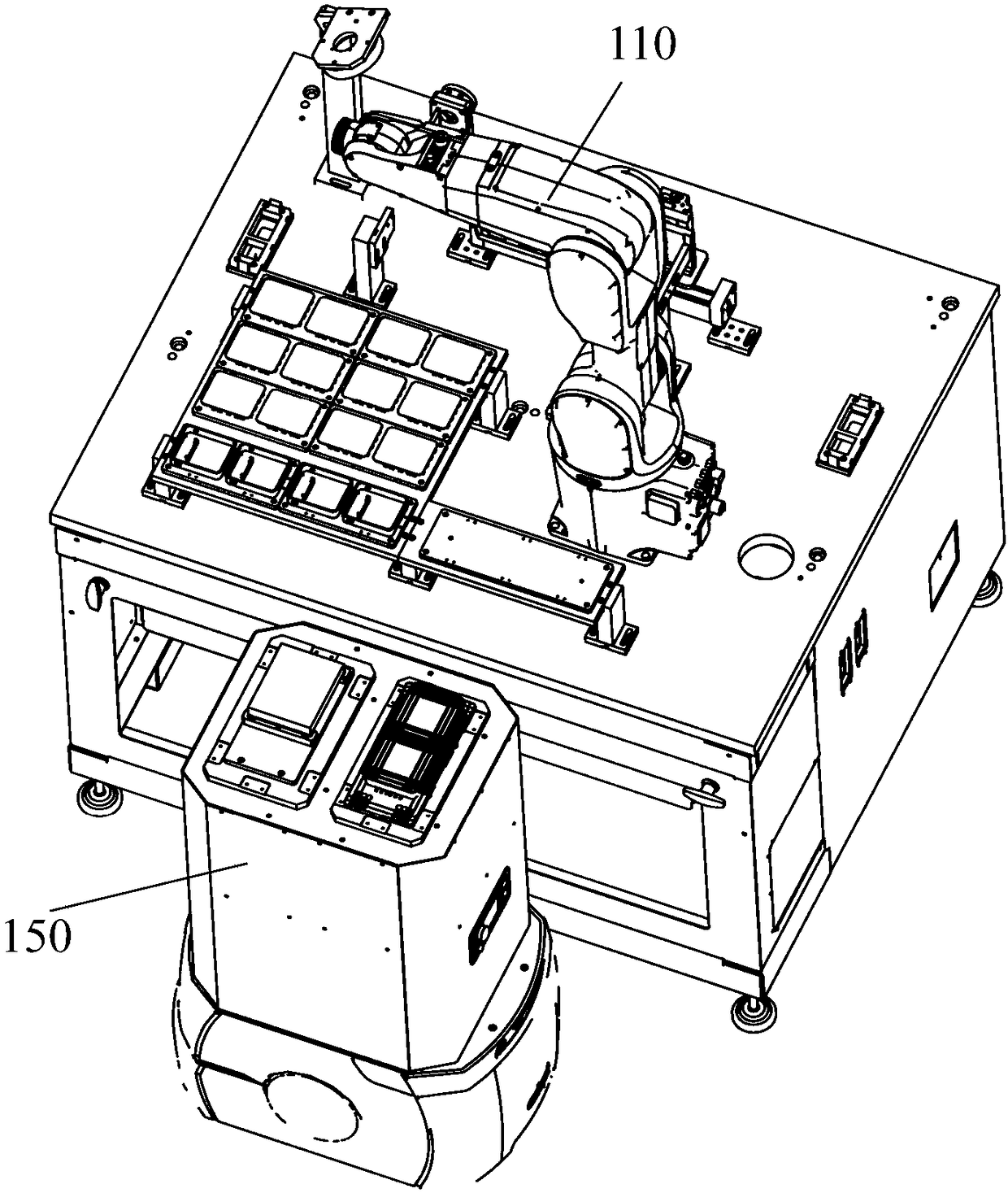

[0029] According to one aspect of the present invention, a visual guidance system is provided.

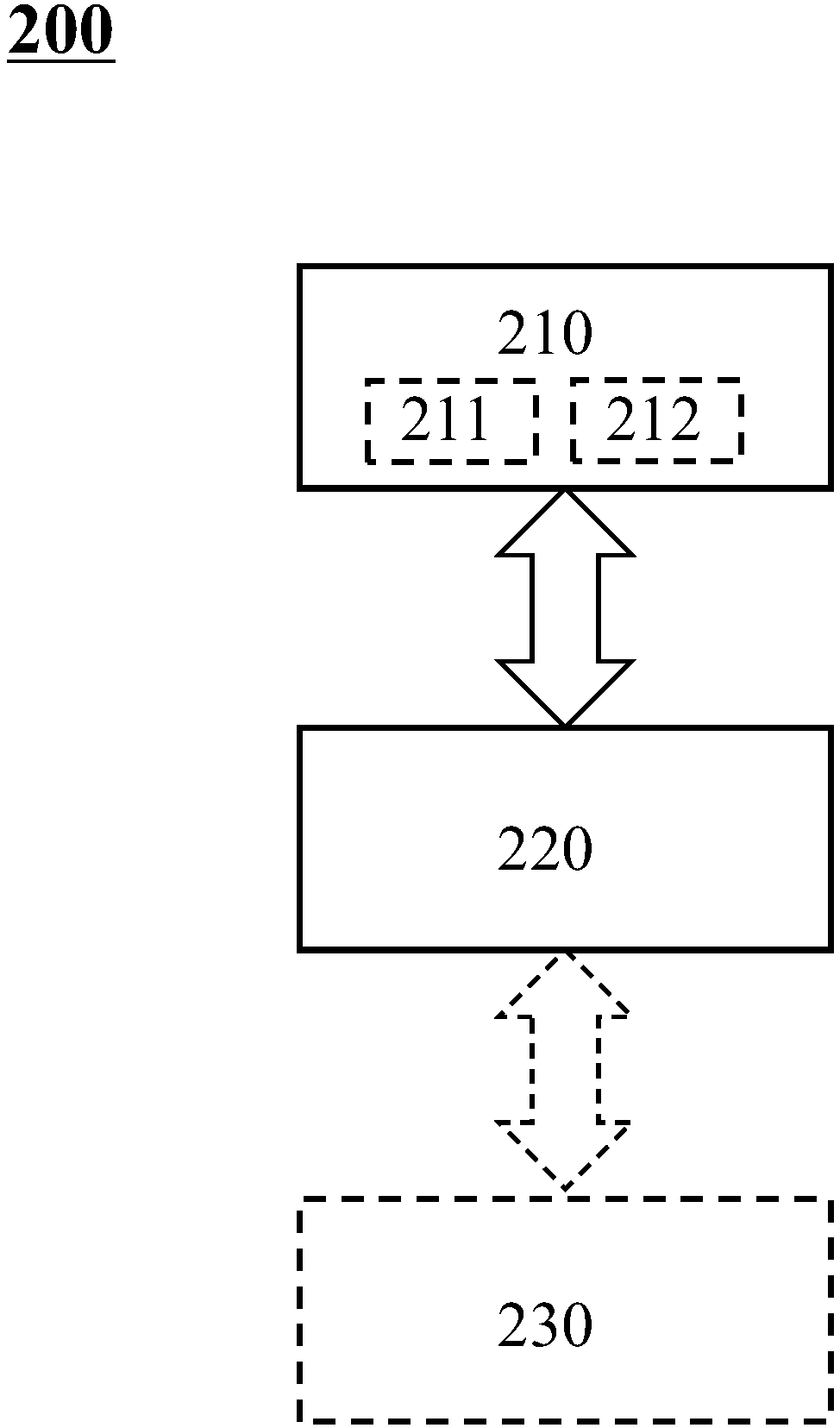

[0030] figure 2 A block diagram of a vision guidance system 200 according to one embodiment of the invention is shown. The vision guidance system 200 may include a vision unit 210 and a programmable logic controller PLC 220 . PLC 220 is communicatively coupled with vision unit 210 . PLC 220 is also communicatively coupled with a robot 230 to be guided by the vision guidance system. In one embodiment, robot 230 may also be part of a vision guidance system.

[0031] The vision unit 210 may include an image capture unit 211 and an image processing unit 212 . The image capture unit 211 is used to capture images, which can be, for example, one or more cameras. The image processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com