Plug contact and method for producing a plug contact

A technology of contacts and contact holes, which is applied in the manufacture of contacts, components of connecting devices, connections, etc., can solve the problems of no contact, small contact-normal force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

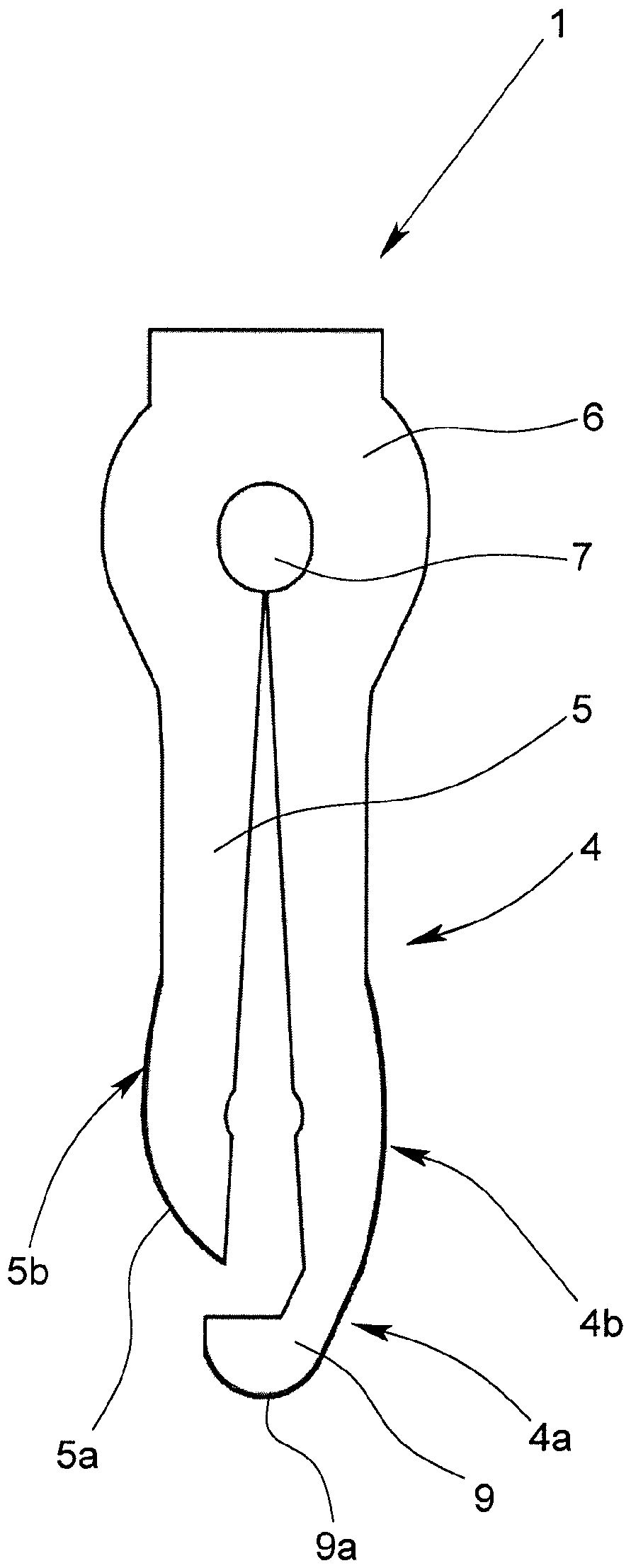

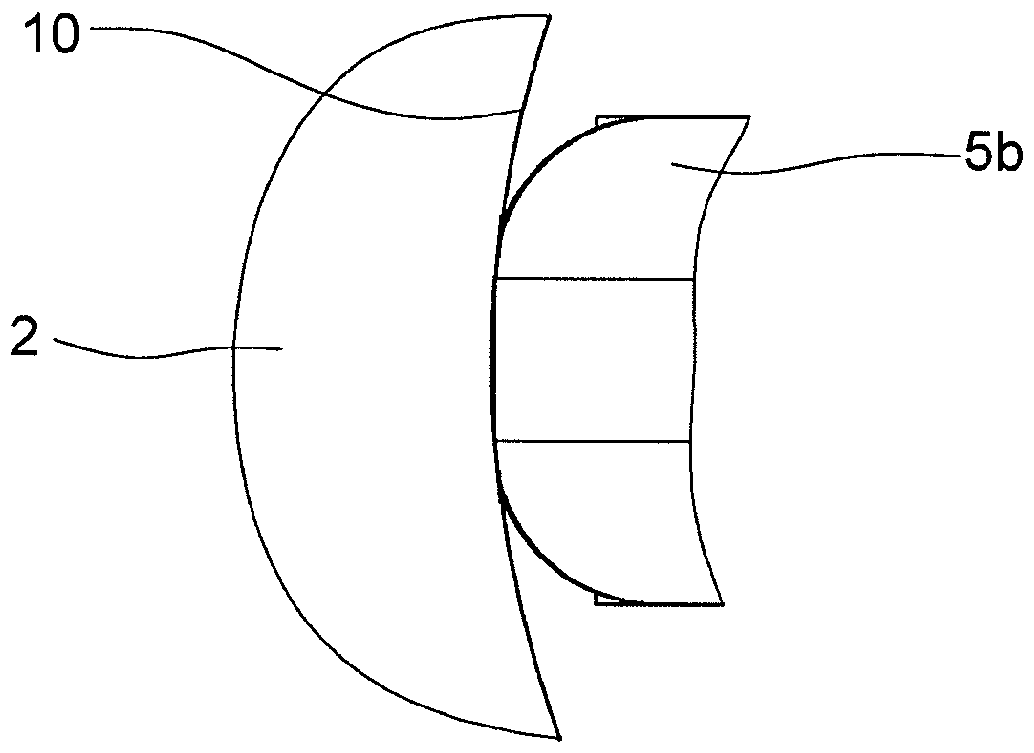

[0030] figure 1 A plug-in contact 11 according to the prior art is shown, which is punched out of a metallic flat material. In contrast, in figure 2 shows a plug contact 1 according to the invention, wherein the plug contact 1 according to the invention is also punched out of a metallic flat material. The two plug-in contacts 1 , 11 serve to contact conductor tracks of the printed circuit board 2 , which are partially shown in FIG. 3 . To this end, the plug contacts 1 are inserted into corresponding contact holes 3 in the circuit board 2 .

[0031] exist figure 1 The known plug-in contact 11 shown in has two contact legs 14 , 15 which are connected to one another via a common connecting region 16 , wherein the contact legs 14 , 15 proceed from the connecting region 16 in the plug-in The plug contact 11 extends in the insertion direction E. In the known plug-in contact 11 , the two contact legs 14 , 15 are produced by punching out the region between the contact legs 14 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com