Sealing composition

A technology for composition and sealing, which is applied in the direction of electrical components, circuits, electroluminescent light sources, etc., and can solve problems such as degradation of organic EL components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

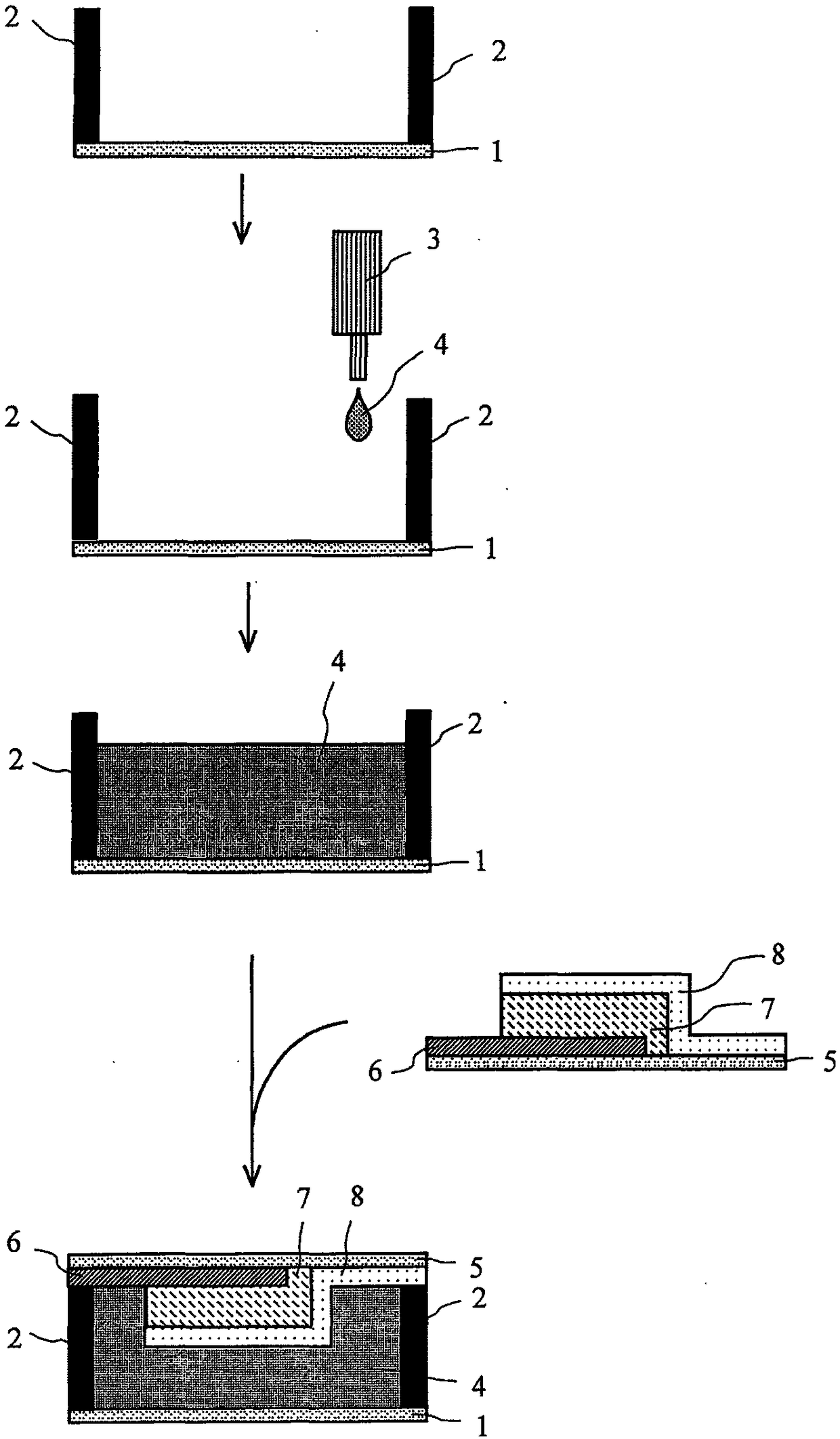

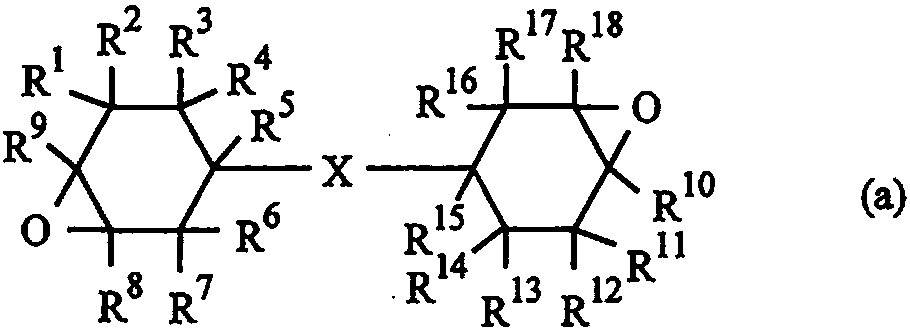

Method used

Image

Examples

Embodiment 1

[0249] According to the formulation described in the table, each component was put into an autorotation-revolution mixer (trade name "Awa-tori Rentaro (あわとり入太郎) ARE-310", manufactured by Thinky Co., Ltd.) and stirred to obtain a composition for sealing (1).

[0250] The obtained sealing composition (1) was coated on a glass substrate to form a coating film (1) (thickness: 100 μm), and ultraviolet rays were irradiated with a mercury lamp (irradiation amount: 1600 mJ / cm 2 ). The viscosity was measured before ultraviolet irradiation, immediately after ultraviolet irradiation, and 30 minutes after ultraviolet irradiation, and the degree of viscosity increase from immediately after ultraviolet irradiation to 30 minutes after ultraviolet irradiation was calculated from the following formula.

[0251] Viscosity increase = Viscosity at 30 minutes after UV irradiation / Viscosity immediately after UV irradiation

[0252] Then, the coating film (1) after ultraviolet-ray irradiation wa...

Embodiment 2~9、 comparative example 1~5

[0255] Except having changed the formulation as described in a table|surface, it carried out similarly to Example 1, and obtained the composition for sealing, obtained the coating film, and obtained the hardened|cured material. In addition, in Example 6, the temperature of post-curing was changed to 150 degreeC.

[0256] With respect to the obtained cured product, the gas discharge rate and water vapor permeability were evaluated by the following methods.

[0257]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap