Titanium alloy human body shoulder joint preform

A shoulder joint and titanium alloy technology is applied in the field of titanium alloy human shoulder joint prefabricated blanks, which can solve the problems of low processing efficiency, material waste, cost increase, etc., and achieve the effects of high effective utilization rate, cost reduction, and longevity satisfaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

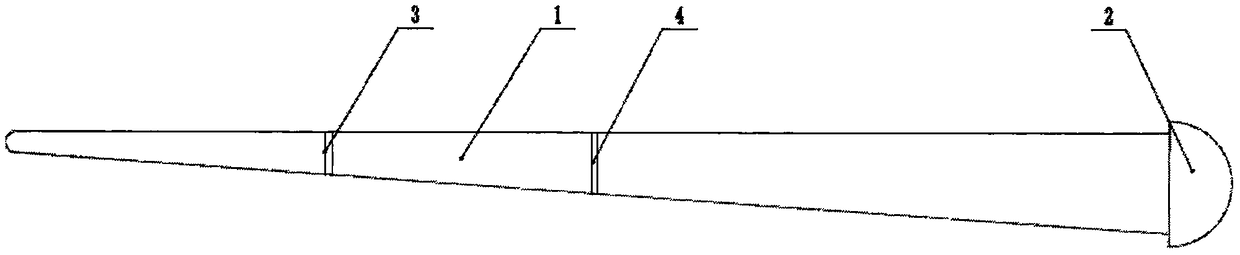

[0014] Below in conjunction with accompanying drawing, the present invention will be further described: figure 1 , figure 2 Shown: a titanium alloy human body shoulder joint preform, including a shoulder joint insertion part 1, the shoulder joint insertion part 1 is a rod-shaped structure with one end thinner and the other end thicker, and the shoulder joint insertion part 1 The shoulder joint hemisphere 2 at the thicker end, the plane of the shoulder joint hemisphere 2 is inserted into the thicker end of the shoulder joint insertion part 1, and the feature is that the distance between the shoulder joint insertion part 1 and the thinner end is 1 / 4 It has a first limit installation groove 3, and the shoulder joint insertion part 1 has a second limit installation groove 4 at 1 / 2 of the thinner end, and the first limit installation groove 3 and the second limit installation groove 4 is a groove with a semicircular cross-section, and the first limiting installation groove 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com