Titanium alloy used for bipolar plate of proton exchange membrane fuel cell

A proton exchange membrane and fuel cell technology, applied in the field of titanium alloys, can solve the problem that corrosion resistance cannot meet the life requirements of proton exchange membrane fuel cells, achieve broad application prospects and economic value, improve service life, and excellent corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

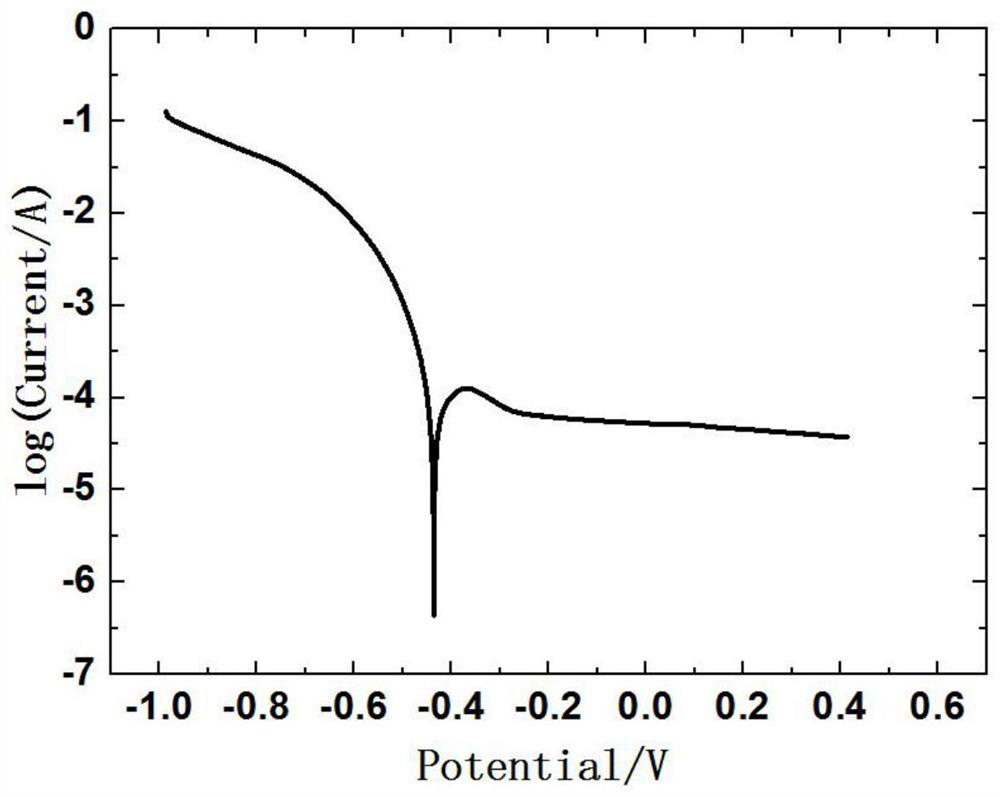

[0020] Specific Embodiment 1: In this embodiment, a titanium alloy used for a bipolar plate of a proton exchange membrane fuel cell, the composition of the titanium alloy conforms to the following form: Ti-X-Z, with pure titanium as raw material, and X and Z as additive elements; wherein X At least one selected from Co and Ni; Z selected from at most four of Cr, Mo, Nb, Ta and V; the total content of X elements in the titanium alloy is 0.1% to 0.6%, and the total content of Z elements is 0.02-0.4%, the balance is composed of Ti and other unavoidable impurity elements.

[0021] The unavoidable impurity elements mentioned in this embodiment are impurities present in titanium alloys such as O, N, C, H, and Si, which are either impurities in the raw materials for preparing titanium alloys, or are impurities introduced during the preparation of titanium alloys. Impurities.

specific Embodiment approach 2

[0022] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the Co, Ni, Cr, Mo, Nb, Ta and V elements are provided by simple substances or master alloys of simple substances and titanium. Others are the same as the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the form of the simple substance is powder, granule or block. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current density | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com