Naphthalene evaporation device used in preparation process of phthalic anhydride

A preparation process and evaporation device technology, applied in the direction of evaporation, evaporator accessories, chemical instruments and methods, etc., can solve the problems of naphthalene pipeline blockage, unstable output, poor evaporation effect, etc., and achieve stable production operation and high production efficiency , Heating effect evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

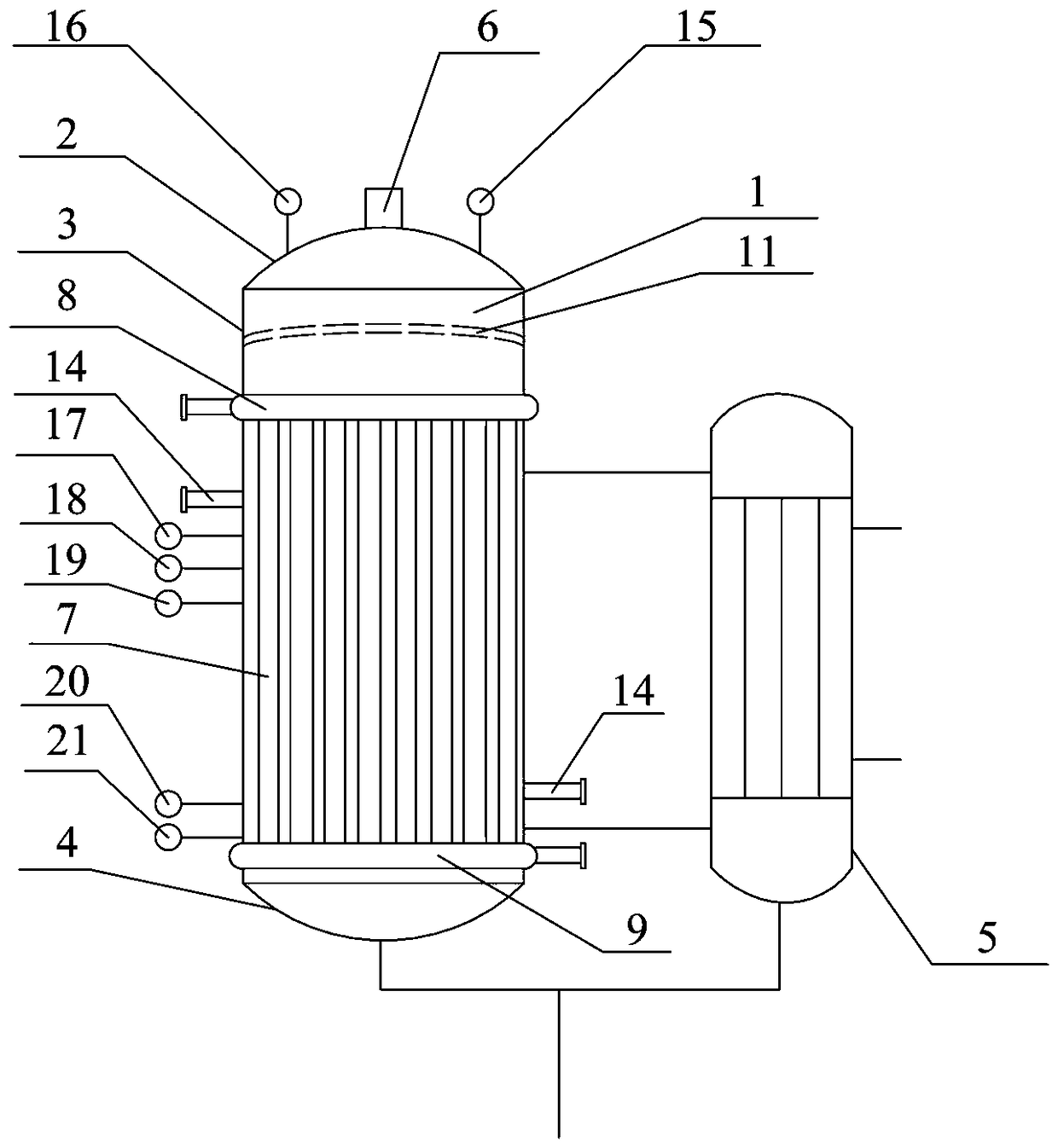

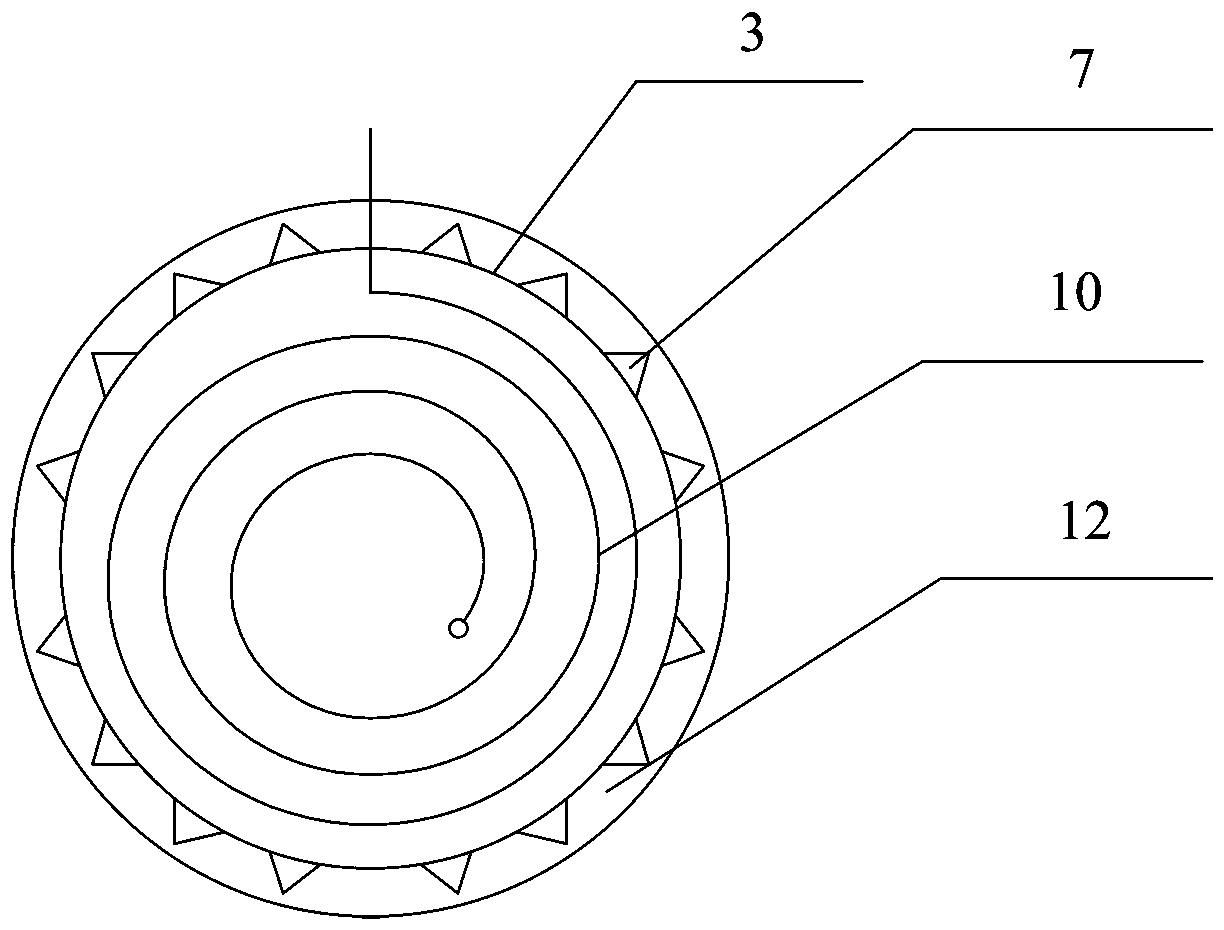

[0021] Such as Figure 1 to Figure 4 As shown, the naphthalene evaporation device in the phthalic anhydride preparation process includes a naphthalene evaporator 1, and the naphthalene evaporator 1 includes an upper head 2, a cylinder 3 and a lower head 4, and the bottom of the cylinder 3 is connected to the naphthalene through a pipeline. The bottom of the reboiler 5, the top of the naphthalene reboiler 5 is connected to the middle and upper part of the cylinder 3, the bottom of the naphthalene reboiler 5 is provided with a heavy component discharge port, and the naphthalene reboiler 5 feeds high-pressure steam to the liquid Naphthalene indirect heating; the top of the upper head 2 is provided with a naphthalene steam outlet 6, the bottom of the lower head 4 is provided with a heavy component discharge port, and the outside of the cylinder 3 is evenly arranged with angle steel 7, and the upper end of the angle steel 7 is connected with The steam inlet passage 8 surrounding th...

Embodiment 2

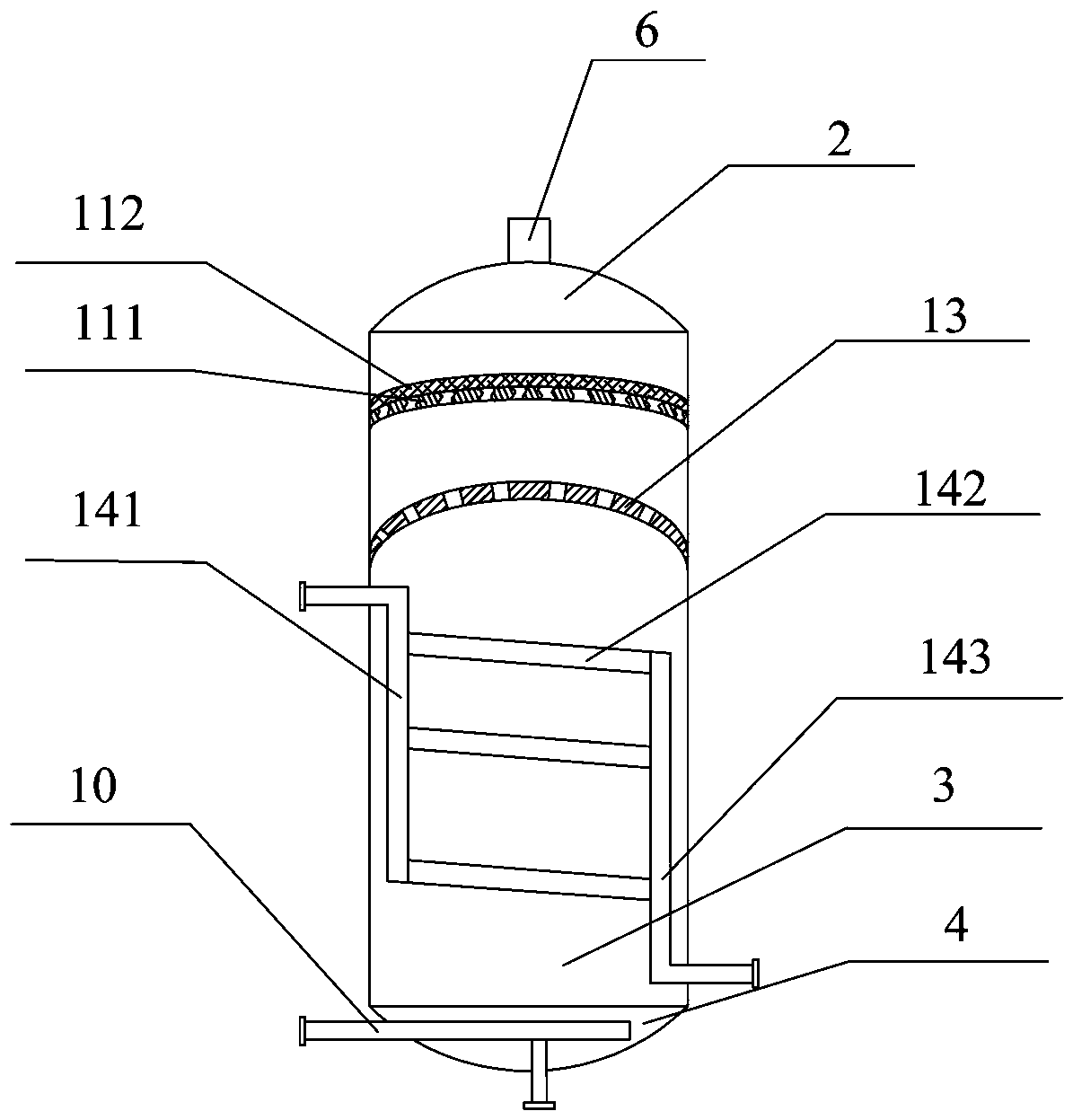

[0023] Such as Figure 1 to Figure 4 As shown, with embodiment 1, the difference is that: the outside of the angle steel 7 is provided with a thermal insulation layer 12; the cylindrical body 3 is provided with a hemispherical retaining plate 13, and the retaining plate 13 is arranged at the position above the liquid naphthalene liquid surface to retain Through holes are evenly arranged on the plate 13; the demister 11 includes a lower primary filter layer 111 and an upper screen layer 112, the primary filter layer 111 is hemispherical, and the primary filter layer 111 is uniformly arranged " S"-shaped channel; the cylinder 3 is provided with a steam heat exchange pipe 14, and the steam heat exchange pipe 14 includes a steam inlet pipe 141, a heat exchange ring pipe 142 and a steam outlet pipe 143, and the heat exchange ring pipe The opposite ends of 142 are respectively connected to the steam inlet pipe 141 and the steam outlet pipe 143, and the heat exchange ring pipe 142 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com