Novel vehicle frame and track frame connecting plug plate

A crawler frame and connecting plug technology, which is applied in the field of crawler cranes, can solve the problems of the inclined surface of the plug plate, the inability to control the gap, and the existence of shear bolts, etc., and achieve the effect of controlling the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

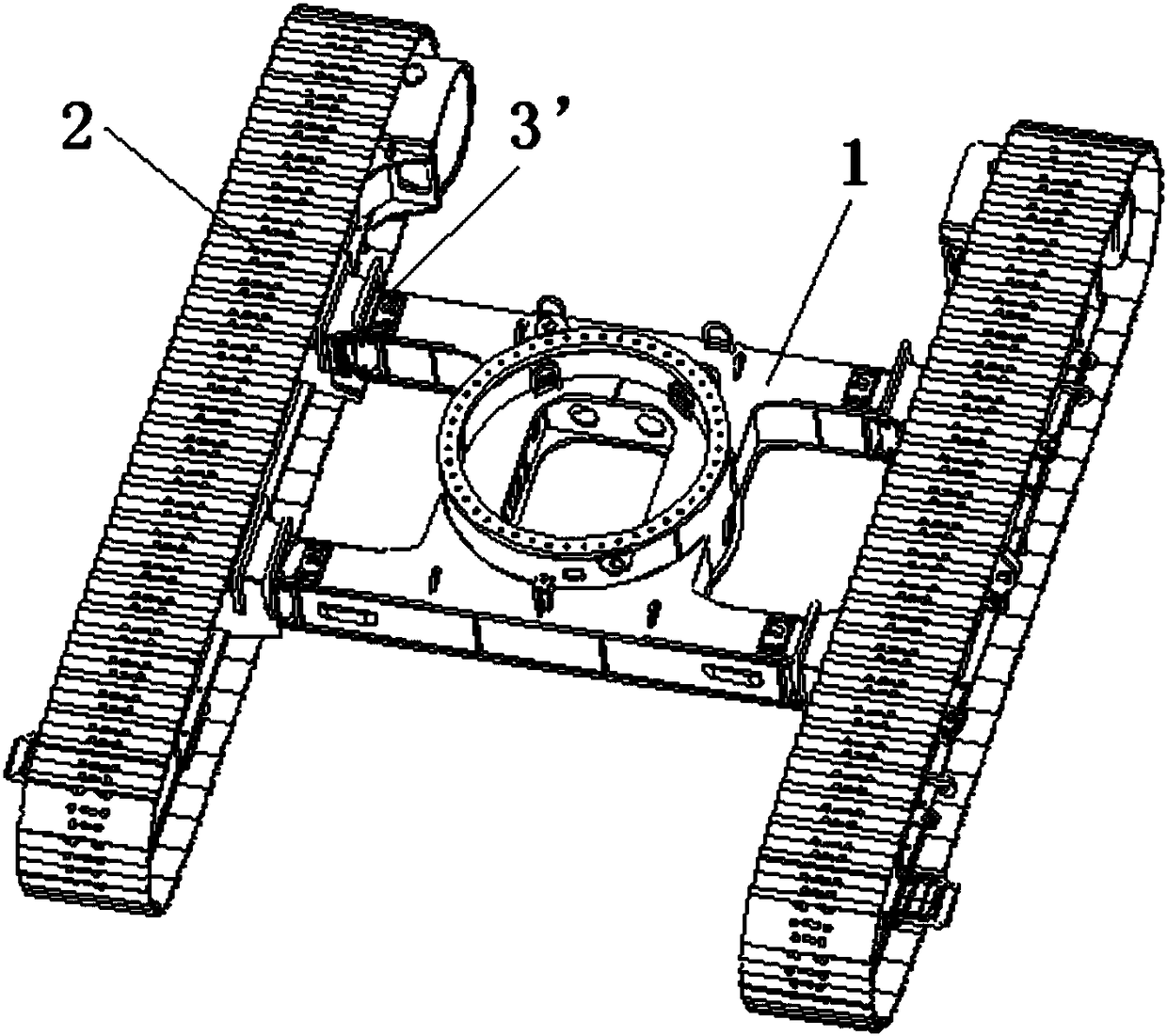

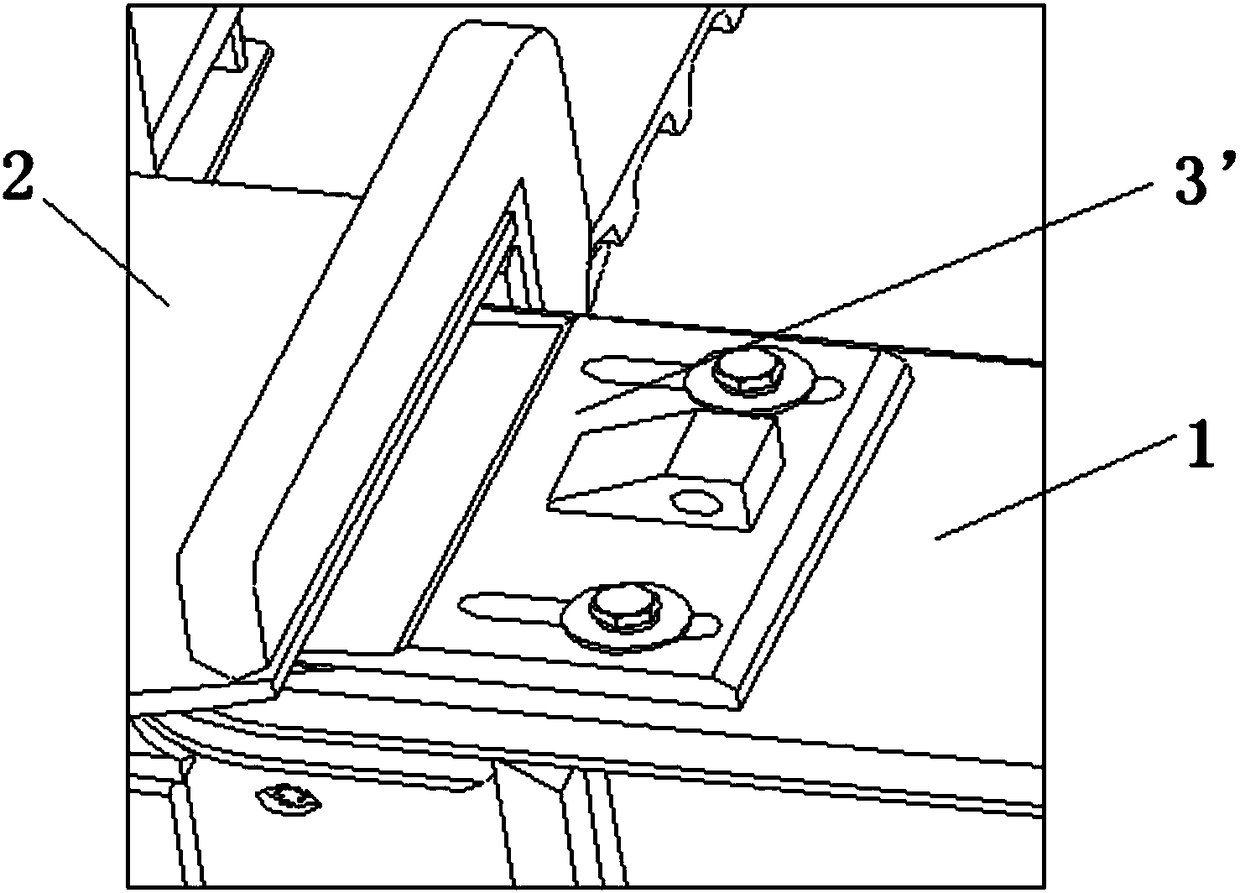

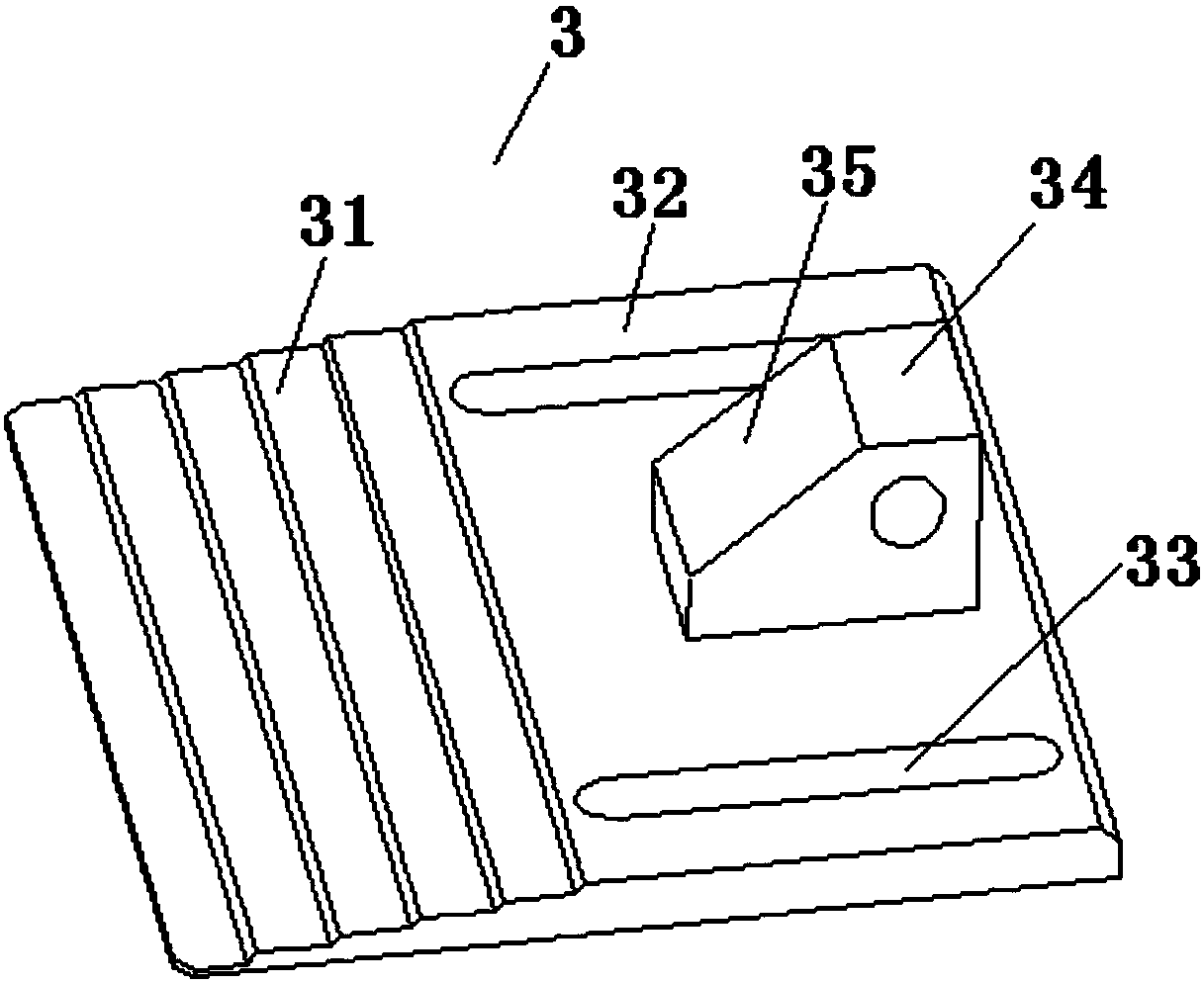

[0023] Since the connection between the vehicle frame 1 and the track frame 2 is tailor-welded, the final gap size cannot be determined, and it is within a certain range. Therefore, the present invention has adopted the plug plate 3 of stepped form, as image 3 As shown, one end of the plug plate 3 of the present invention is a stepped surface 31 facing and in contact with the upper cover plate of the track frame 2; the other end is a fixed end 32 which can be fixedly connected with the vehicle frame. The fixed end 32 is provided with two elongated holes 33, and the plug plate 3 can be fixed on the vehicle frame 1 through the elongated holes 33 by bolts; The side is an inclined surface 35 tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com