PTA powder chain plate conveying system

A conveying system and chain conveying technology, which is applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of unstable PTA powder conveying, increase the use of nitrogen and energy consumption, and affect the production progress, etc., to achieve excellent airtightness performance, reduce dust pollution, and improve the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and described below through specific embodiments in conjunction with the accompanying drawings. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

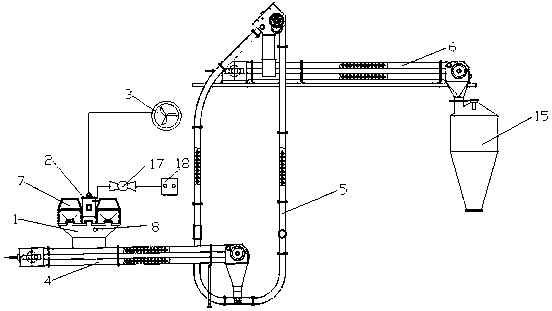

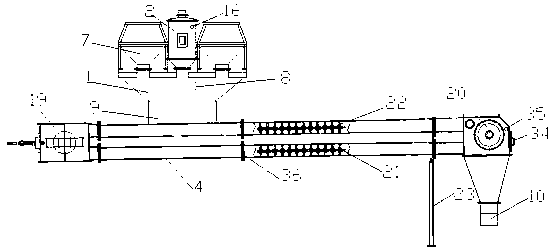

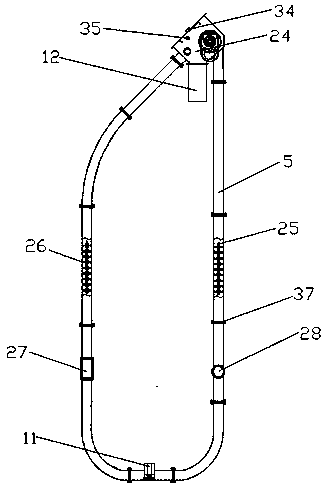

[0024] Such as Figure 1-4 Shown, a kind of PTA powder chain conveyor system, it includes feeding system, dust removal system and conveying system, described feeding system includes feeding trough 1, dust removal system includes dust remover 2 and dust removal blower 3, and conveying system includes sequentially connected The first horizontal pipe chain conveyor 4, the second vertical pipe chain conveyor 5 and the third horizontal pipe chain conveyor 6; the top of the feeding trough 1 is provided with a manual feeding hopper 7, and the side wall is provided with a tank car unloading Port 8, the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com