Automatic mounting and demounting method and device of counterweight of engineering machine and engineering machine

A construction machinery, automatic loading and unloading technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of increasing hand-held equipment, low efficiency, low cost performance, etc., to achieve the effect of convenient operation, high efficiency, and reduced auxiliary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0059] see Figure 4 , this embodiment provides a method for automatically loading and unloading the counterweight of construction machinery, and this embodiment takes the automatic hanging process as an example to specifically introduce the method for automatically loading and unloading the counterweight of construction machinery. The method for automatically loading and unloading the balance weight of construction machinery includes the following steps:

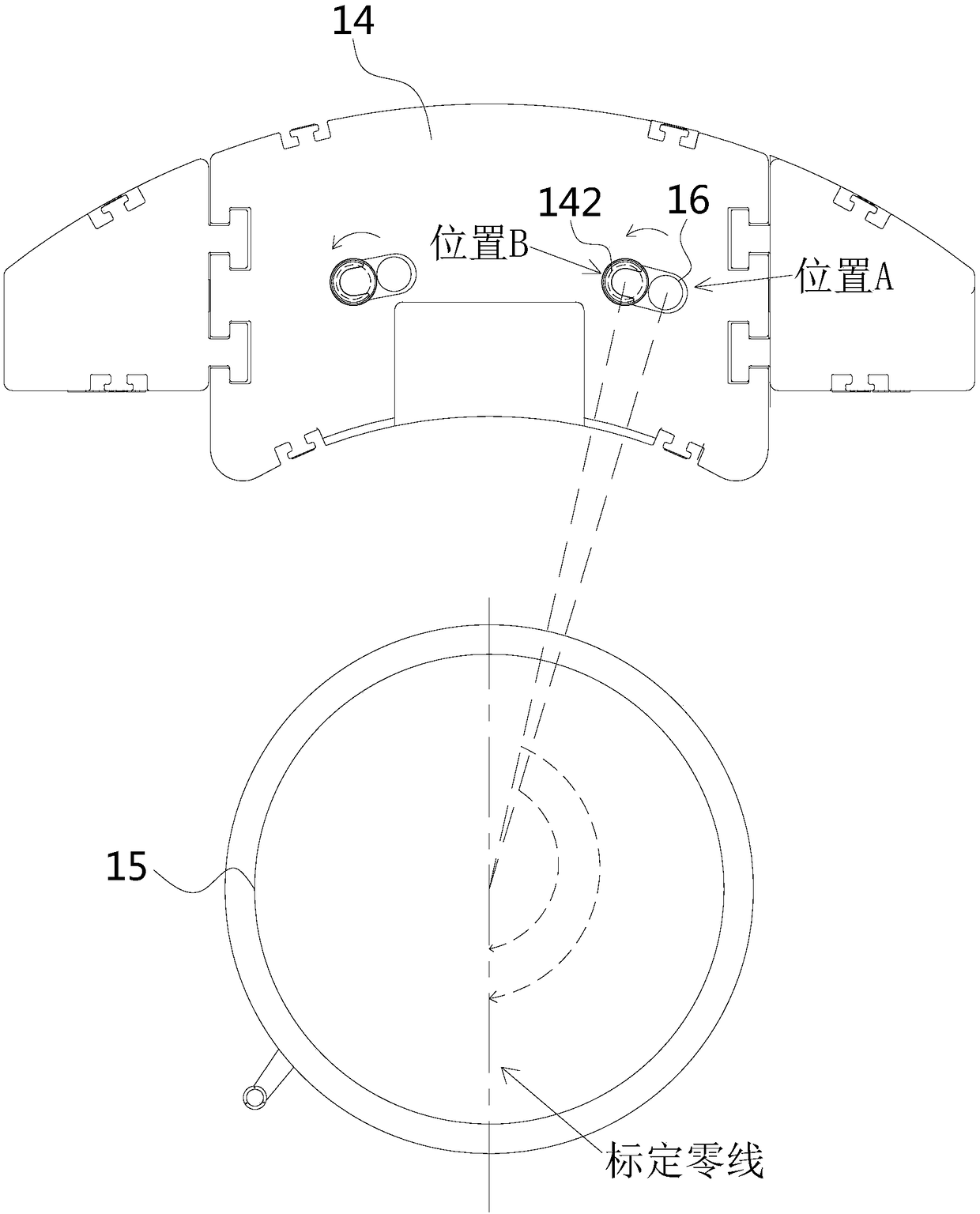

[0060] Step S101 , in response to the operation of the control handle of the construction machine 10 , control the rotation mechanism 15 of the construction machine 10 to rotate, and drive the counterweight tray 14 of the construction machine 10 to rotate to a first calibration angle position. Wherein, the first calibration angle position indicates that the angle between the projection of the block 16 of the vertical oil cylinder of the construction machine 10 on the counterweight tray 14 and the center of rotation of the s...

no. 2 example

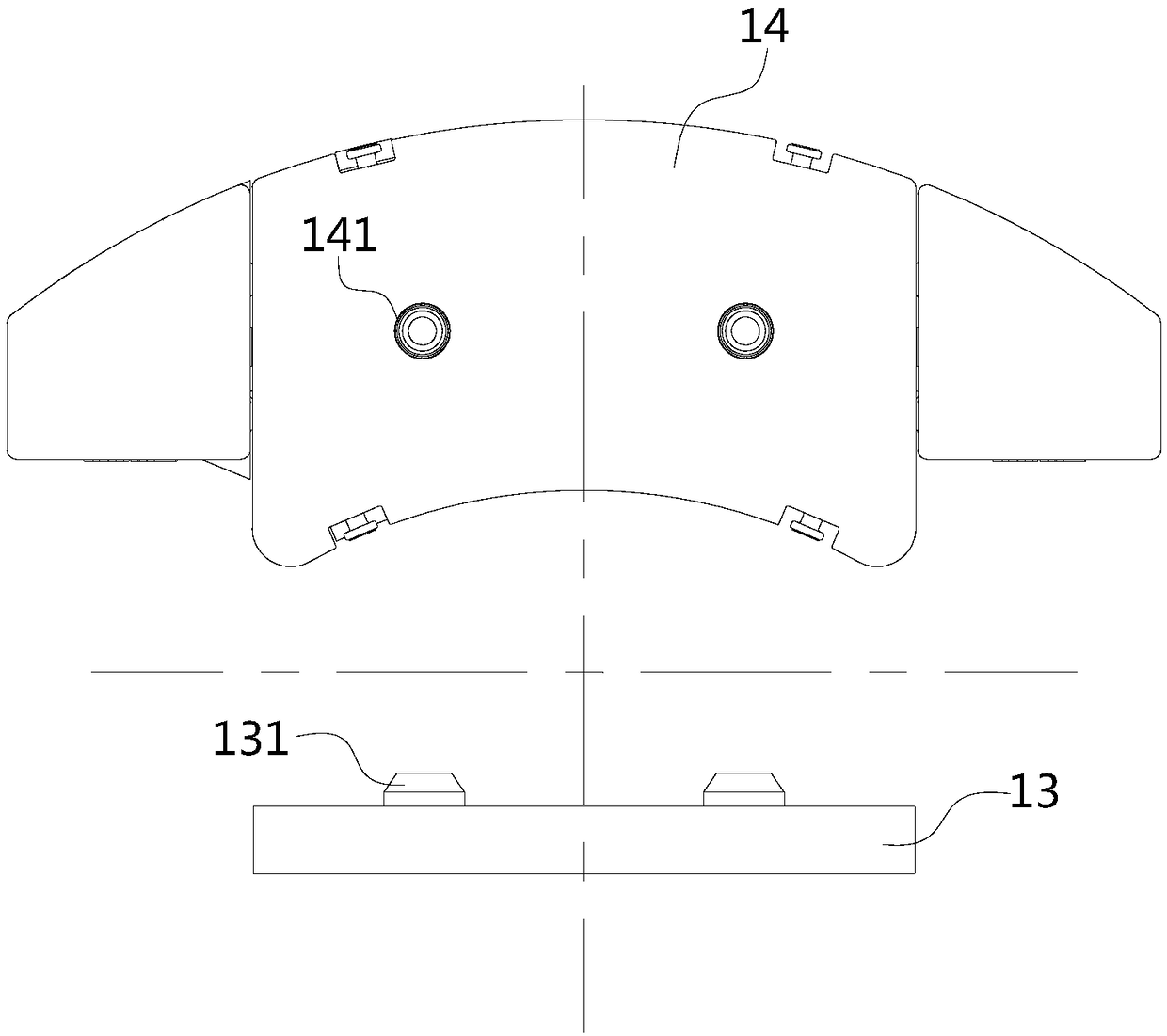

[0088] see Figure 2-Figure 4 , this embodiment provides a method for automatically loading and unloading the counterweight of construction machinery, and this embodiment specifically introduces the method for automatically loading and unloading the counterweight of construction machinery by taking the automatic unloading process as an example. The flow chart of this embodiment can refer to the first embodiment. The difference between the automatic loading and unloading method of the construction machinery counterweight in this embodiment and the first embodiment is that the initial state is different. In this embodiment, in the initial state, the balance weight has been hung up. , the clamping block 16 and the clamping slot 142 have been assembled, and the automatic unloading process of the counterweight is realized through the automatic loading and unloading method of the construction machinery counterweight in this embodiment. Only the differences between this embodiment an...

no. 3 example

[0096] see Figure 8 , this embodiment provides a method for automatic loading and unloading of construction machinery counterweights, which, on the basis of the first embodiment and the second embodiment, further includes an angle calibration step, which is used to calibrate the first calibration angle and the second calibration angle , to determine the first calibration angle position and the second calibration angle position.

[0097] In this embodiment, the step of angle calibration is before the above step S101, which includes the following steps:

[0098] Step S201 , setting the calibration zero line of the slewing mechanism 15 .

[0099] In this embodiment, the quantitative displacement rotation angle of the rotation mechanism 15 is marked as 0, and it is confirmed that one rotation corresponds to 360°. Among them, the calibration zero line is indicated by the dotted line in the attached drawing.

[0100] Step S202 , hoisting the balance weight to be hung onto the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com