Reinforced rail vibration-damping fastener

A vibration-damping fastener and reinforced technology, which is applied in the field of rail transit, can solve problems such as unsatisfactory vibration-damping performance and lateral stiffness, and achieve the effects of compact structure, convenient operation, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

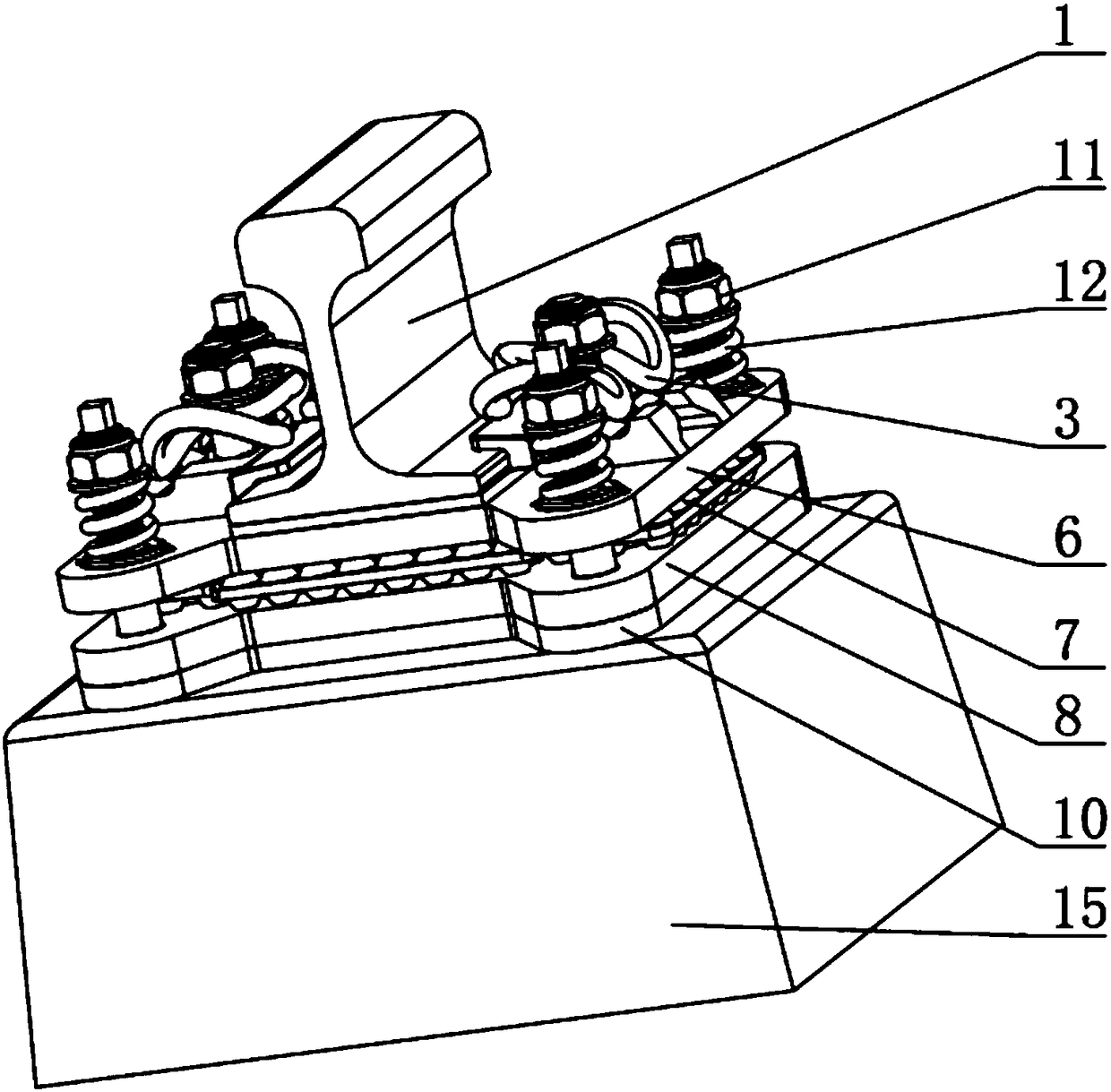

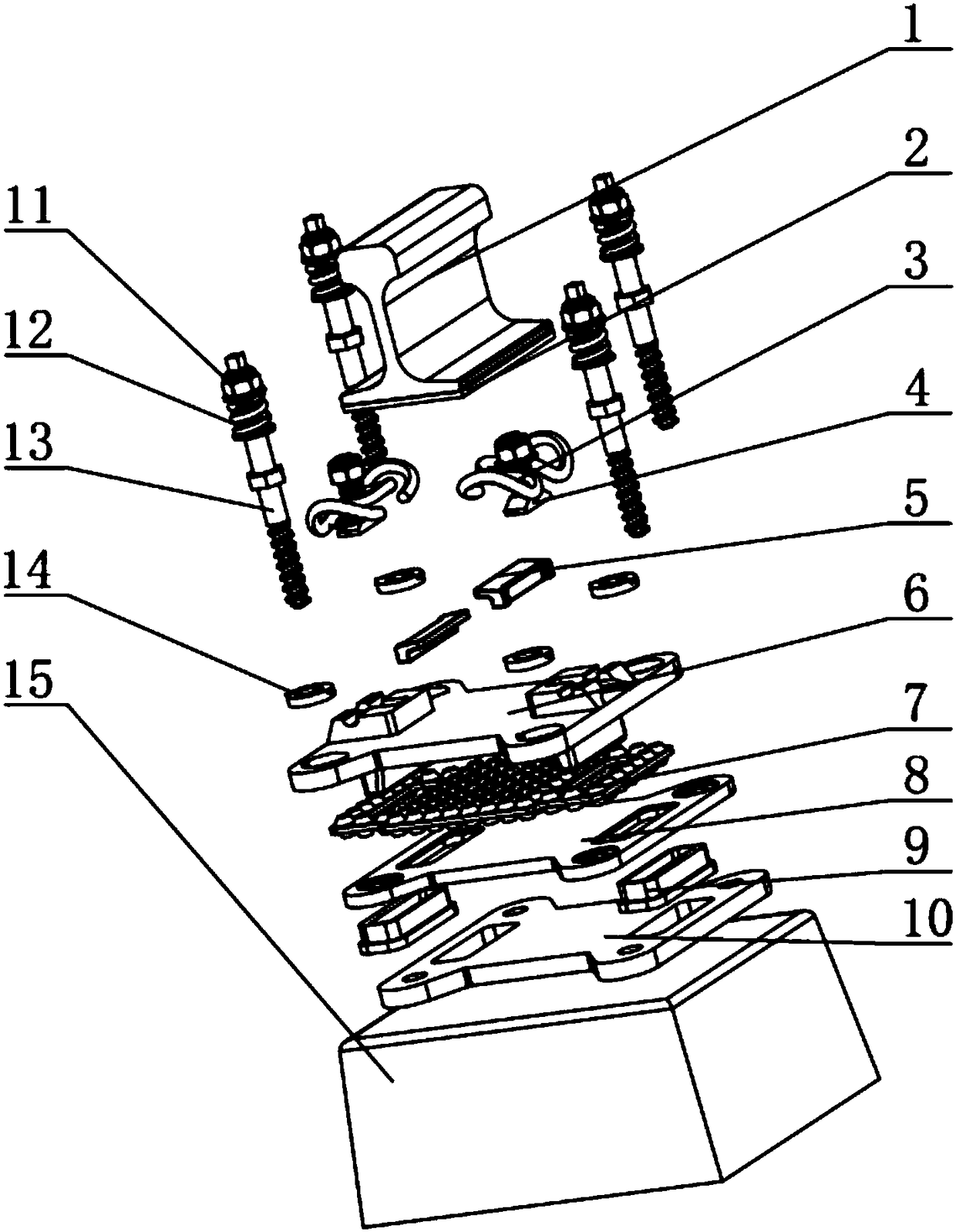

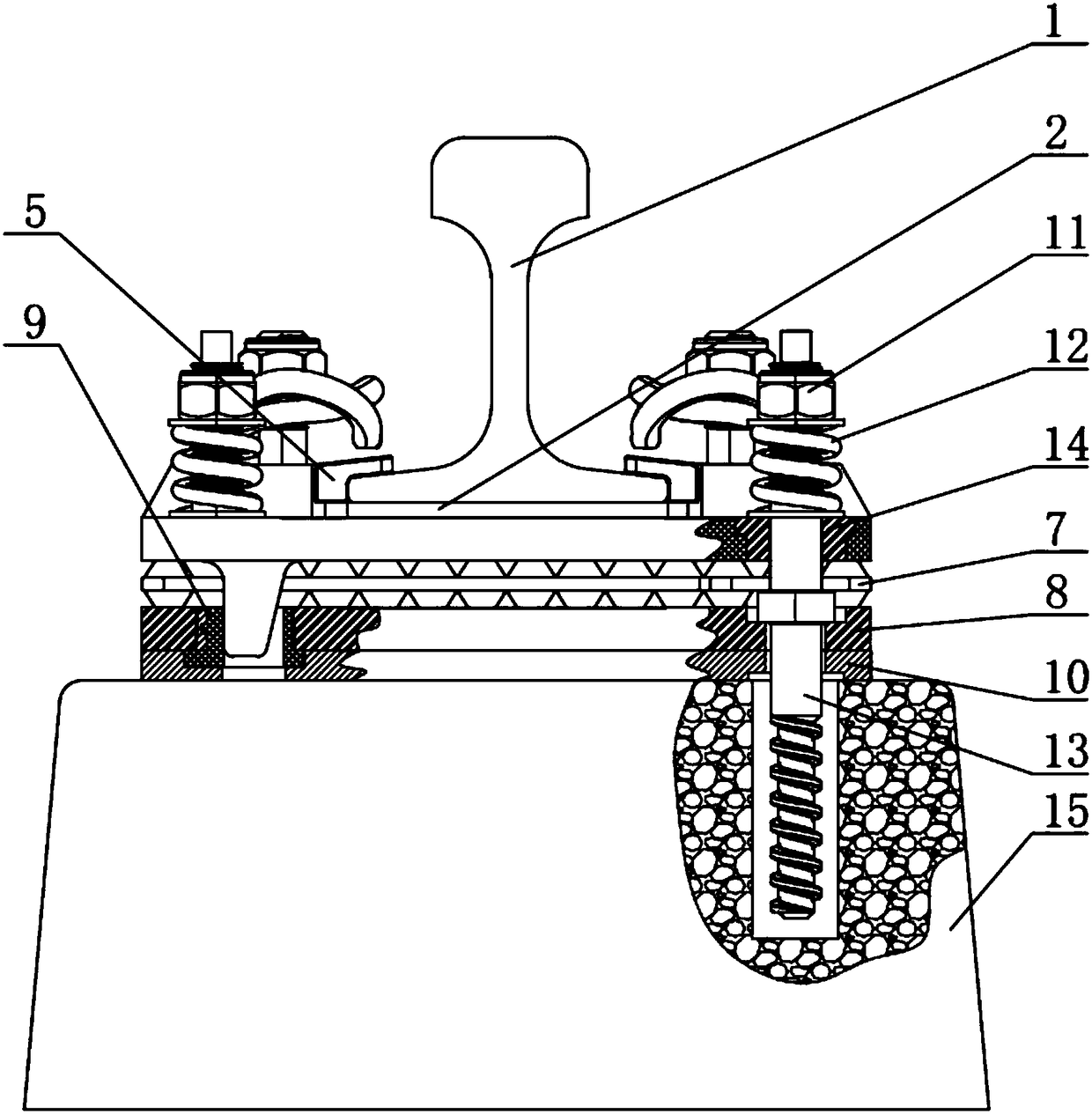

[0029] Such as figure 1 , figure 2 with image 3 As shown, the reinforced track damping fastener of this embodiment includes a short sleeper 15, and the lower iron backing plate 8 and the under-board backing plate 10 are anchored on the short sleeper 15 through the lower thread of the stud bolt 13, and the under-board backing plate The plate 10 is located at the bottom of the lower iron backing plate 8, the two ends of the lower backing plate 10 and the lower iron backing plate 8 are respectively slotted, and elastic sliding sleeves 9 are respectively installed in the slots; the upper surface of the lower iron backing plate 8 The floating iron backing plate 6 is installed through the vibration-isolation rubber backing plate 7. The bottom of the floating iron backing plate 6 is provided with a wedge-shaped shoulder 604. The wedge-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com