Rail maintenance equipment with rail rust removal and crack repair functions

A technology for maintaining equipment and tracks, which is applied in track maintenance, tracks, and track laying, etc. It can solve problems affecting the mechanical properties of rails, long repair time for cracks, clean rail waists, etc., achieve good rust removal effect, save manpower, and prevent spattering The effect of less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

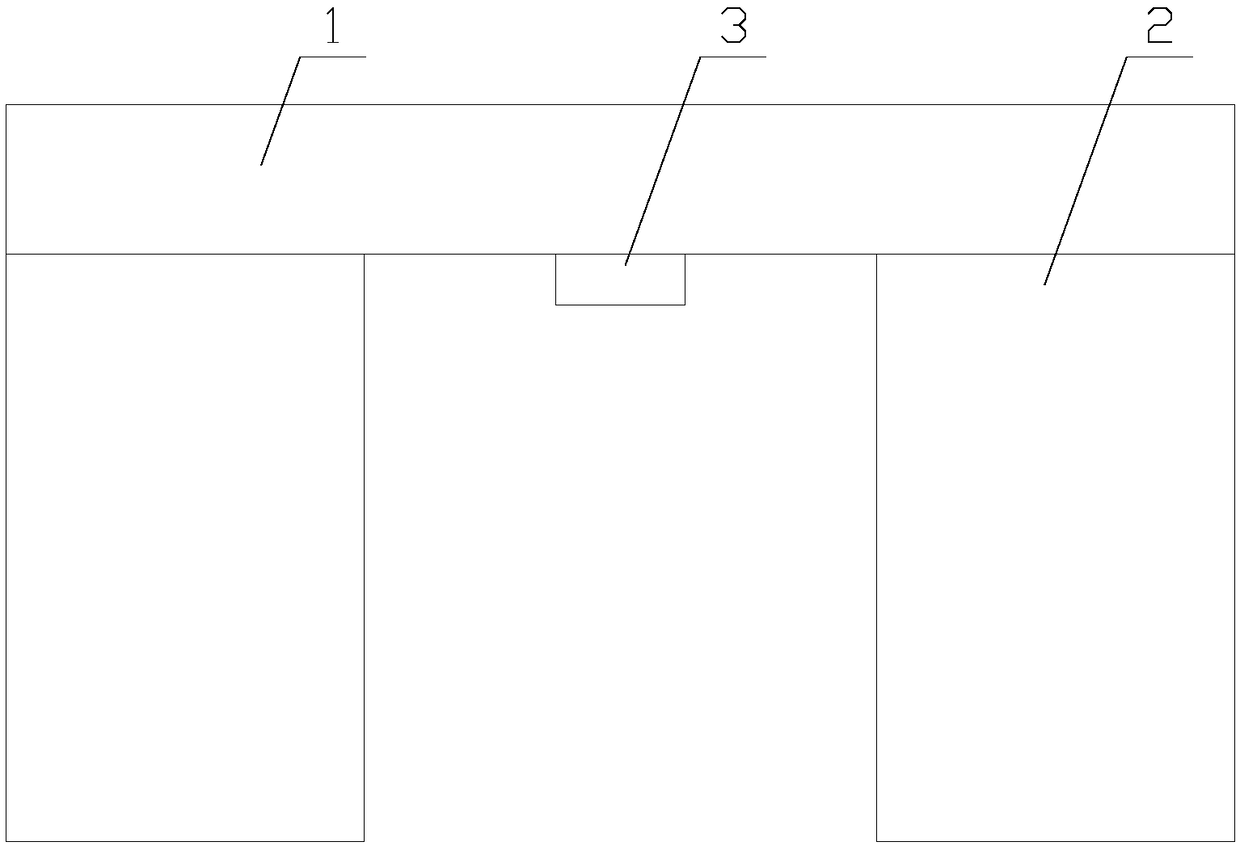

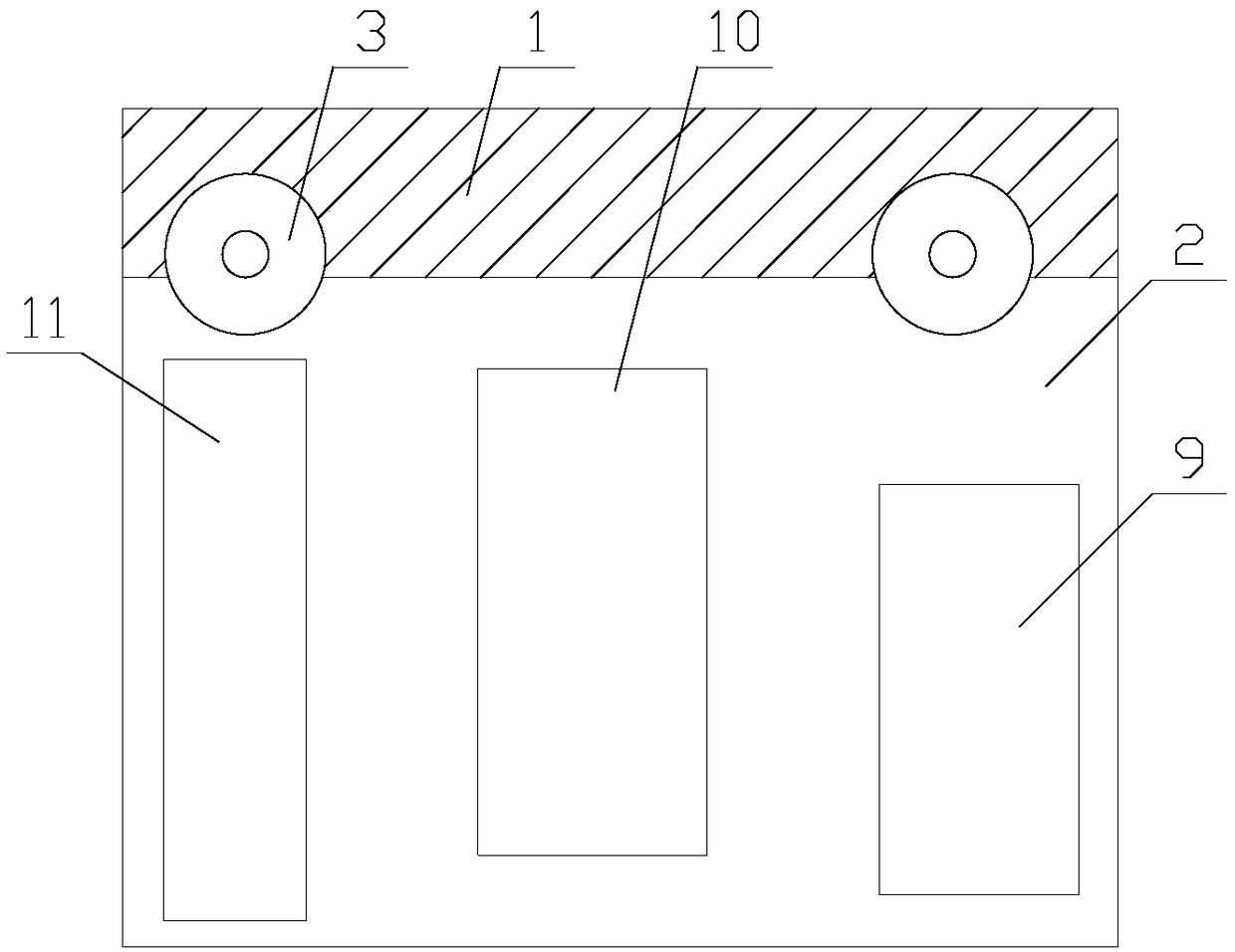

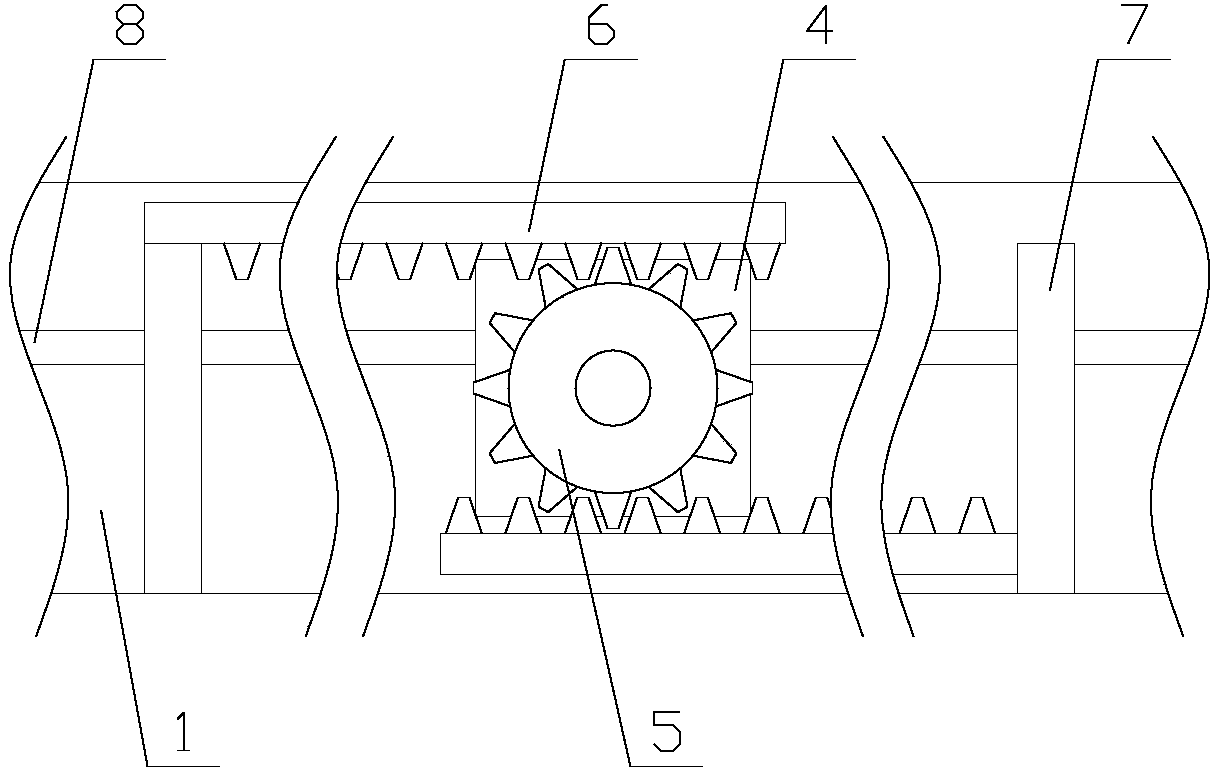

[0035] Such as Figure 1-2 As shown, a track maintenance equipment with track derusting and crack repairing functions includes a beam 1, two working boxes 2 and at least two moving wheels 3, and the two working boxes 2 are arranged under the beam 1, and two The working boxes 2 are respectively arranged on both sides of the crossbeam 1, and each moving wheel 3 is arranged between the two working boxes 2, and each moving wheel 3 is evenly distributed under the crossbeam 1, and the crossbeam 1 is provided with a clamping mechanism. The first groove 9, the second groove 10 and the third groove 11 are arranged in the described working box 2, and the first groove 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com