Automobile adjusting shock absorber and damping adjusting method thereof

A shock absorber and adjustment technology, which is applied in the field of automobile adjustment shock absorber damping adjustment and automobile adjustment shock absorber, can solve problems such as difficult operation, achieve cost saving, simple and convenient adjustment method, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

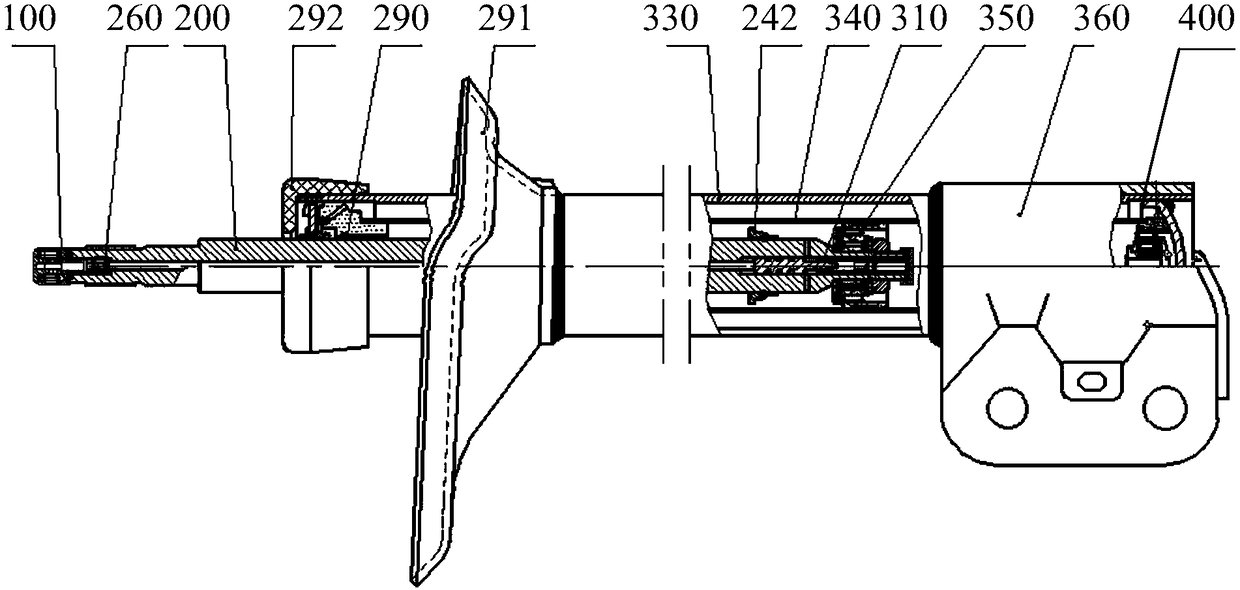

[0059] like figure 1 As shown, the automobile tuning shock absorber provided by the present invention includes: a damping tuning actuator 100 , a piston rod 200 and a valve train 300 .

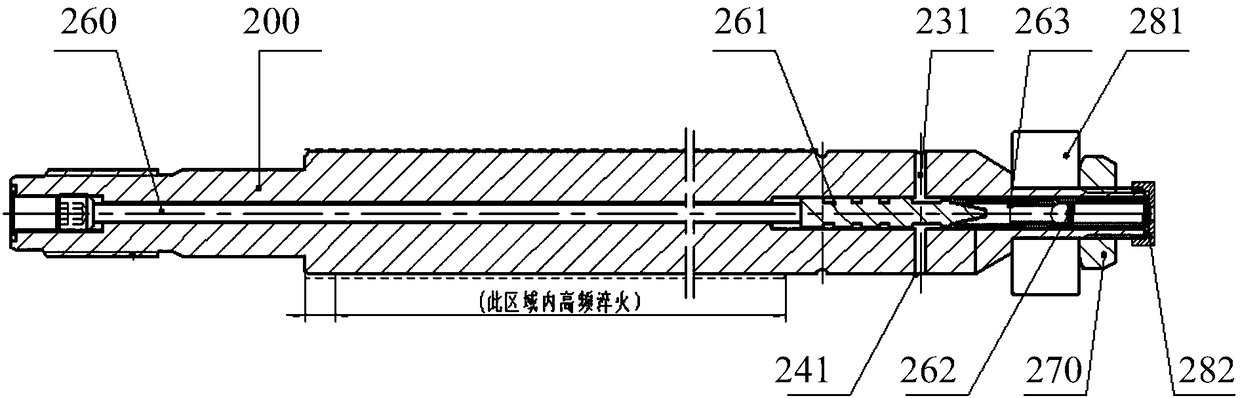

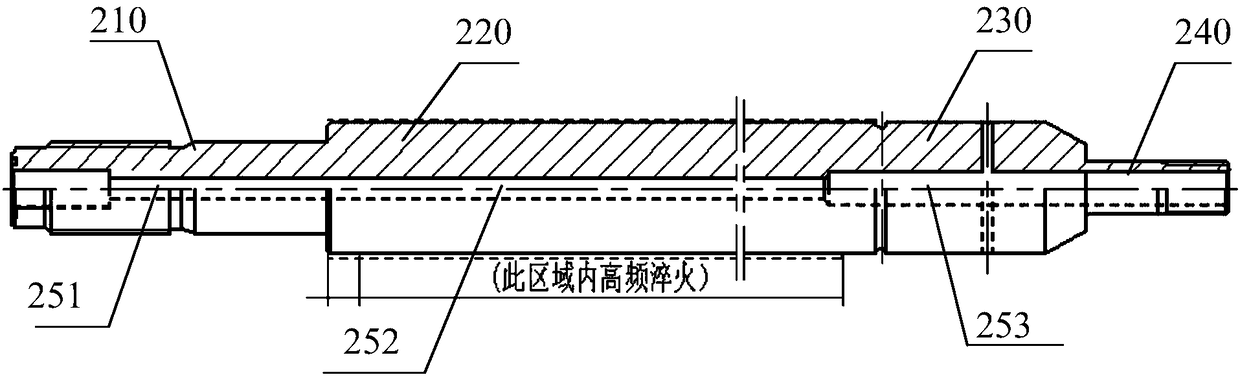

[0060] The piston rod 200 is hollow, and the hollow rod cavity is used for installing the adjusting rod 260 and the throttle valve assembly 310 . Both ends of the piston rod have a threaded structure, and the user end also has an internal threaded structure. There is a cross hole 231 on the piston rod 200, so that the oil generates a small hole high pressure during the recovery stroke of the piston rod. The shaft section with the largest shaft diameter of the piston rod has a section area that is subjected to high-frequency quenching treatment to enhance its mechanical properties.

[0061] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com