A gas-liquid separator assisted air conditioner system and its control method

A gas-liquid separator and control method technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of increasing the pressure drop gradient on the side of the refrigerant, hindering the evaporation of liquid-phase refrigerant, etc., and reduce the flow resistance loss. , The effect of reducing the rate of frost formation and increasing the evaporation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

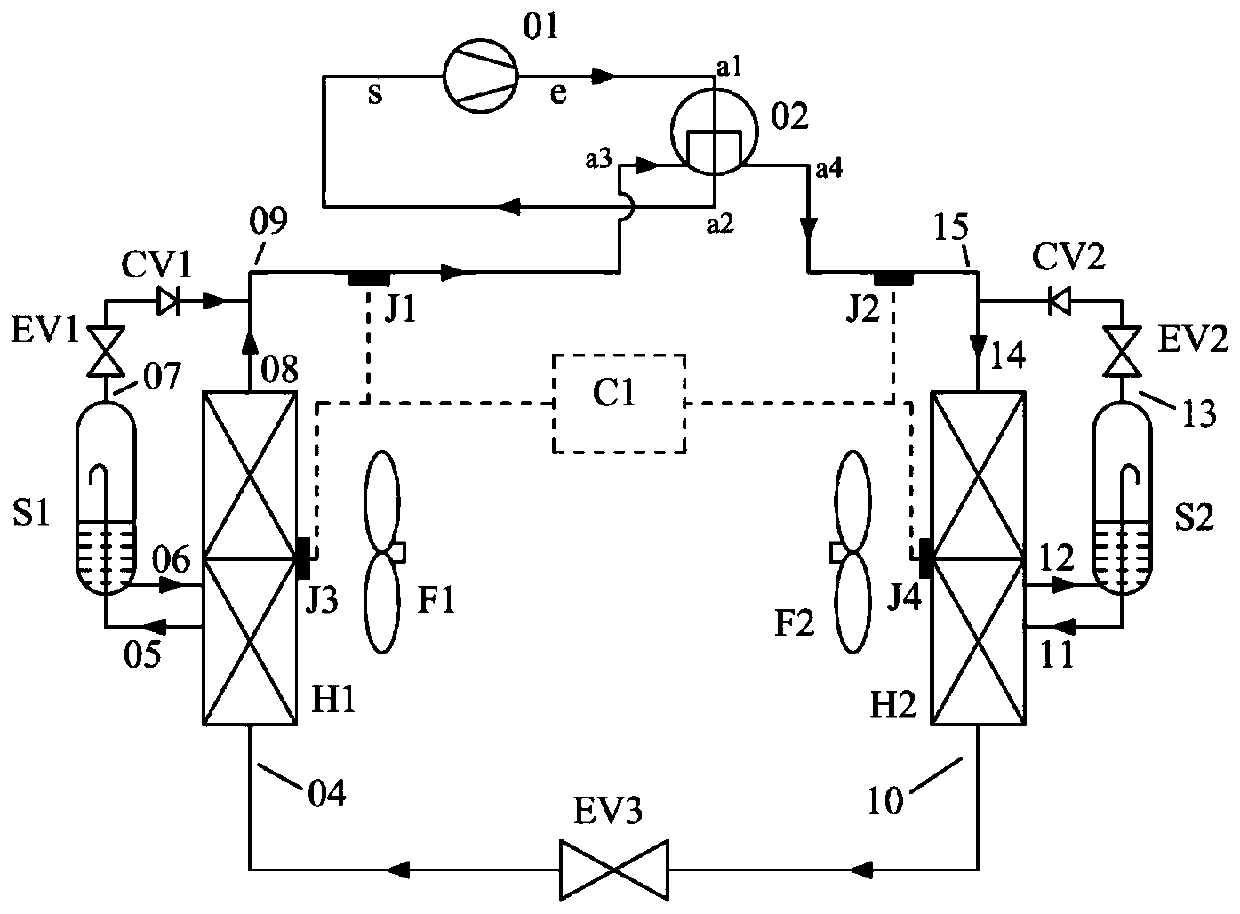

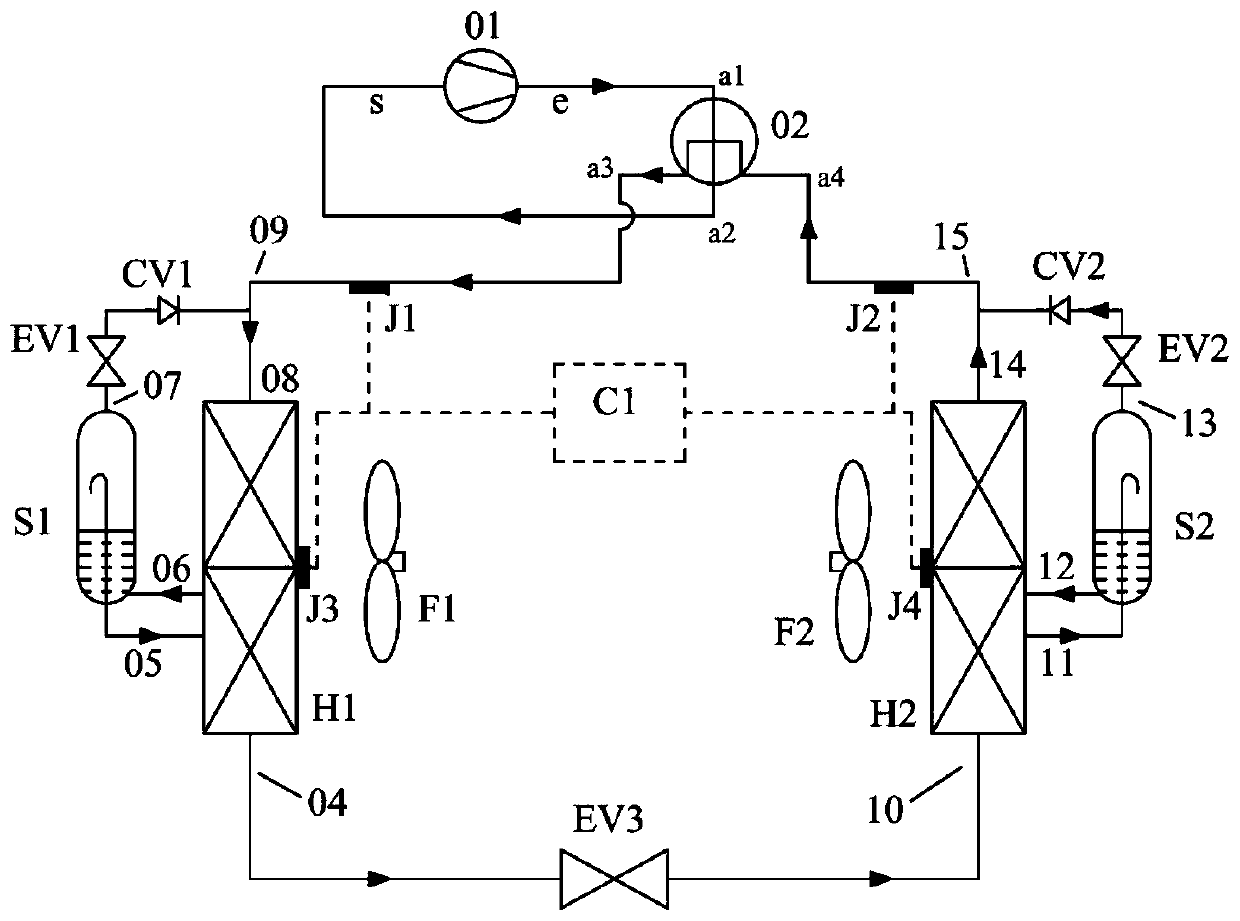

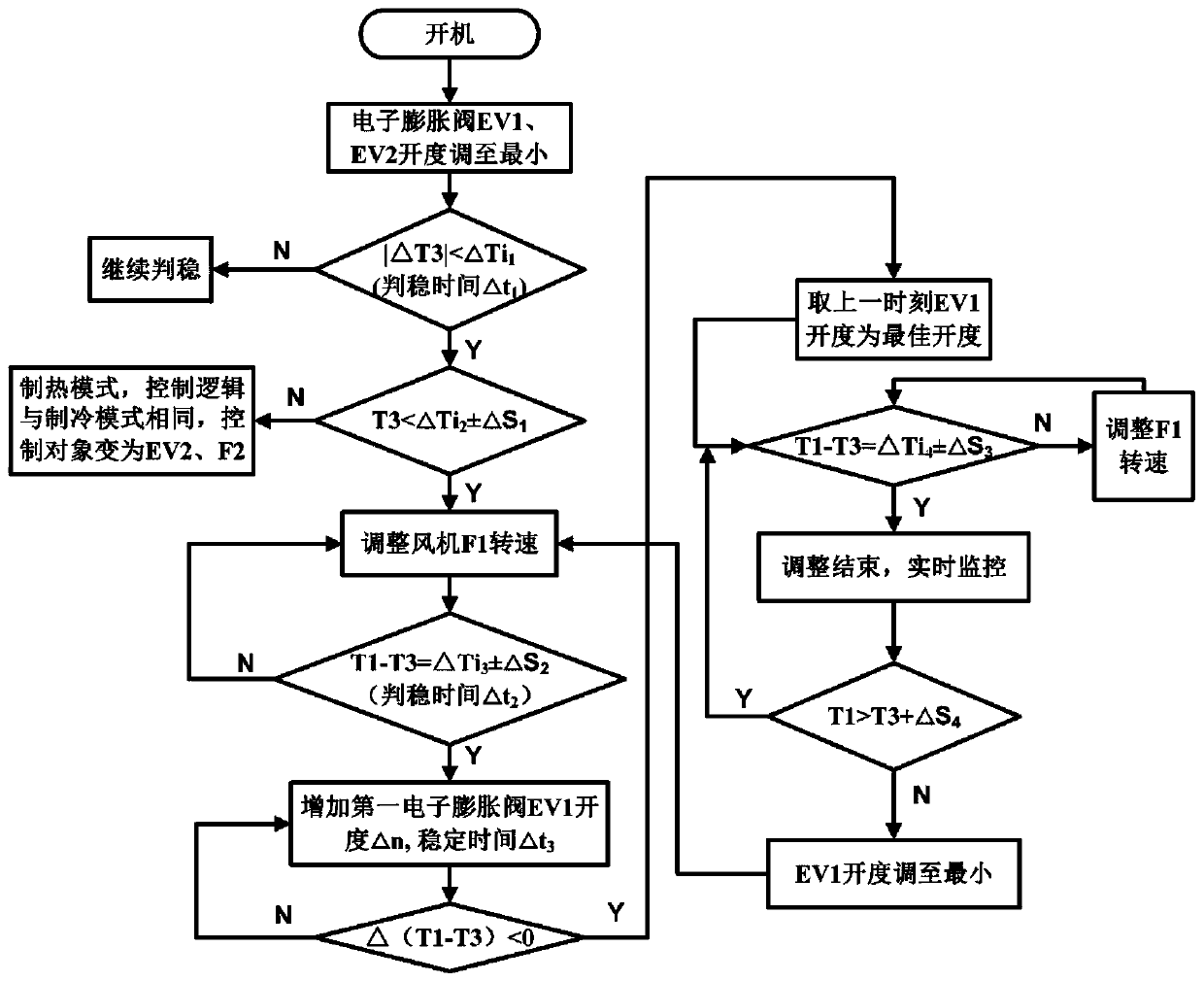

[0025] Such as figure 1 and figure 2As shown, in the cooling mode, the indoor heat exchanger H1 acts as an evaporator, and the outdoor heat exchanger H2 acts as a condenser; the refrigerant enters the indoor heat exchanger through the third electronic expansion valve EV3 and enters the indoor heat exchanger through the evaporation process inlet 04 of the indoor heat exchanger. Heater H1 evaporates and exchanges heat. The refrigerant flows through the first half of the indoor heat exchanger and enters the first gas-liquid separator S1 through the inlet 05 of the first gas-liquid separator. The liquid-phase refrigerant flows from the liquid-phase outlet of the first gas-liquid separator. 06 enters the second half of the indoor heat exchanger H1 and continues to participate in heat exchange. The gas-phase refrigerant flows out fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com