Rock sample processing device

A processing device and rock sample technology, applied in the field of rock sample processing devices, can solve the problems of easy confusion, tedious and time-consuming, inconvenient batch processing and management of source rocks, and achieve the effect of avoiding dumping and convenient batch processing and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

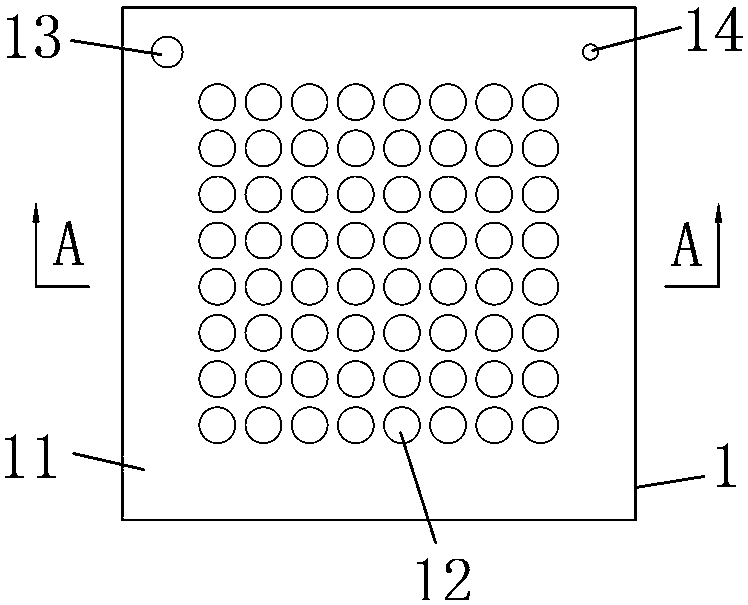

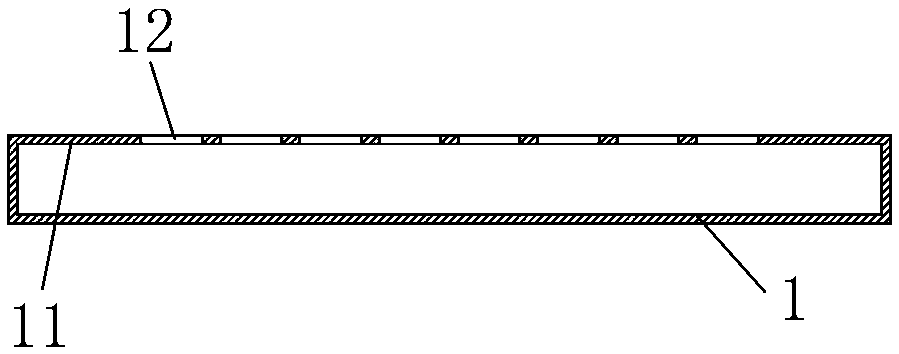

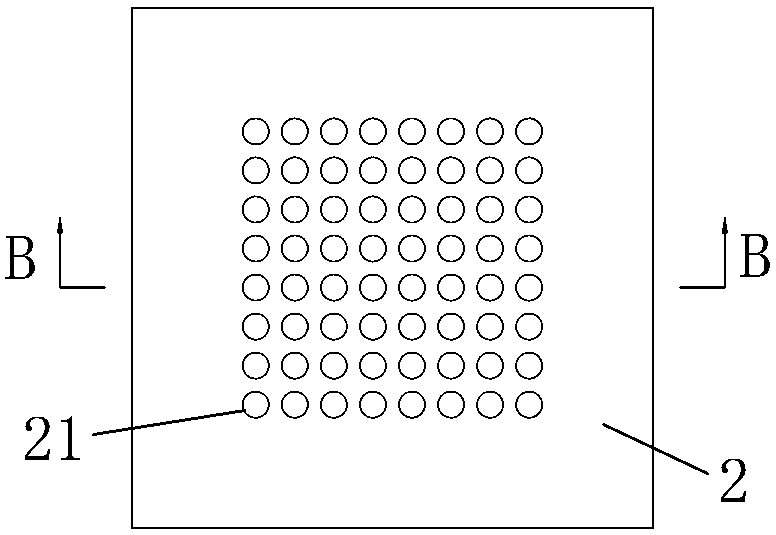

[0022] Embodiment 1 of the rock sample processing device of the present invention is as Figure 1~4 As shown, it includes a box body 1 and a tray assembly. The box body 1 has an end face supporting the tray assembly. In this embodiment, the end face supporting the tray assembly is the upper end face of the top cover 11. The storage cup 21 that the loading tray 2 is integrally provided with, in the present embodiment, there are 64 storage cups and are distributed on the loading tray in a matrix form of eight rows and eight columns. In other embodiments, the storage cups are also It can be 36, 81 and other numbers, and can also be discretely distributed on the loading tray; the plane where the mouth of the holding cup 21 is located is on the same level as the upper end surface of the loading tray 2, and the holding cup 21 is all extended into Inside the box body 1; a top cover 11 is integrally provided on the box body 1, and the box body 1 and the top cover 11 are both rectangul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com