Convolutional neural network based ribbon edge burr defect detection method

A convolutional neural network and defect detection technology, applied in the field of webbing edge defect detection, can solve the problems of consuming computing resources, huge amount of computing, and increasing the total amount, so as to improve computing performance, increase computing amount, and reduce computing volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

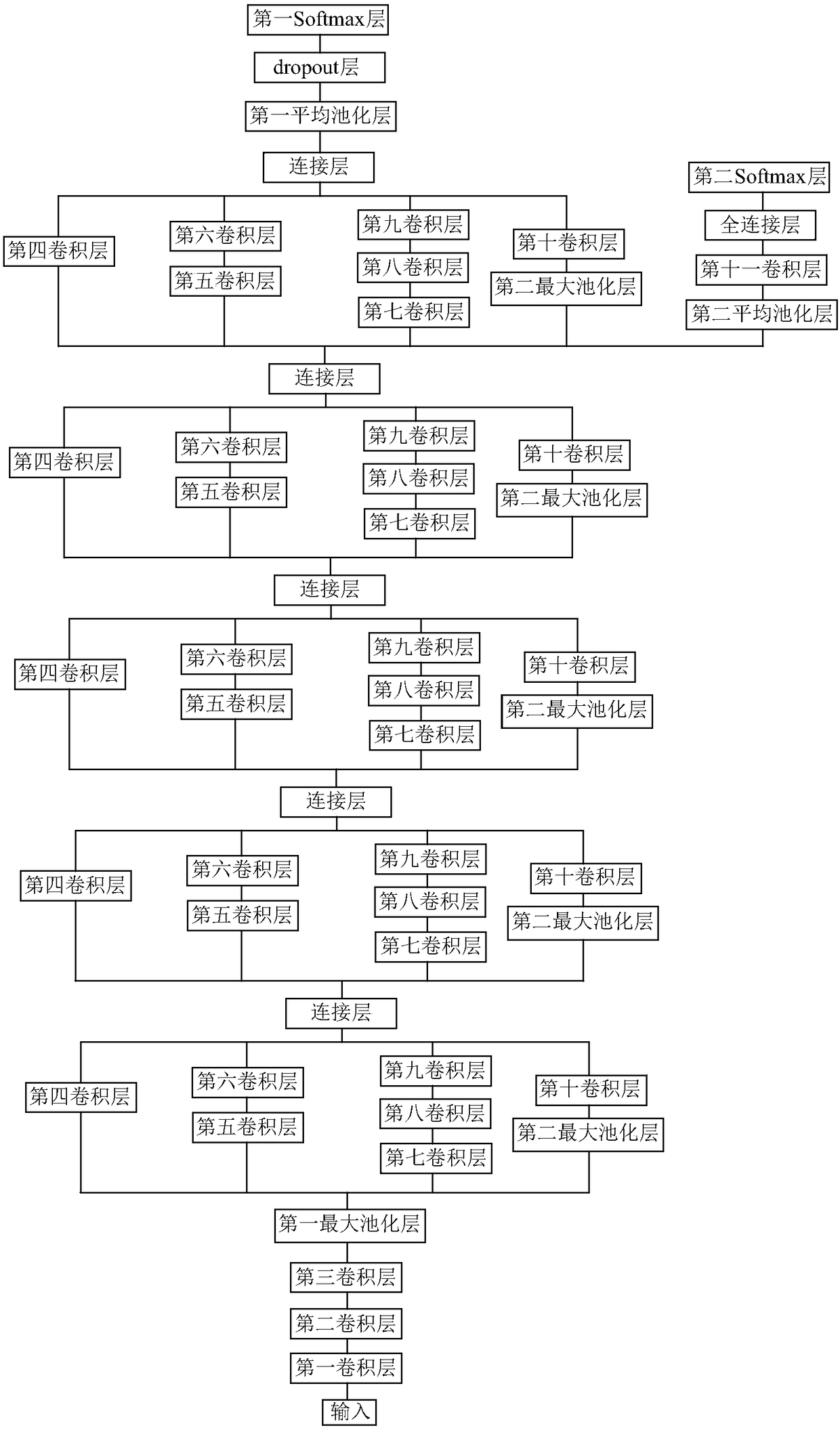

[0035] refer to figure 1 - figure 2 , a kind of webbing edge blemish defect detection method based on convolutional neural network of the present invention, comprises the following steps:

[0036] A. Image acquisition and preprocessing to obtain sample images;

[0037] B. Perform image enhancement processing on the sample picture to obtain the training picture;

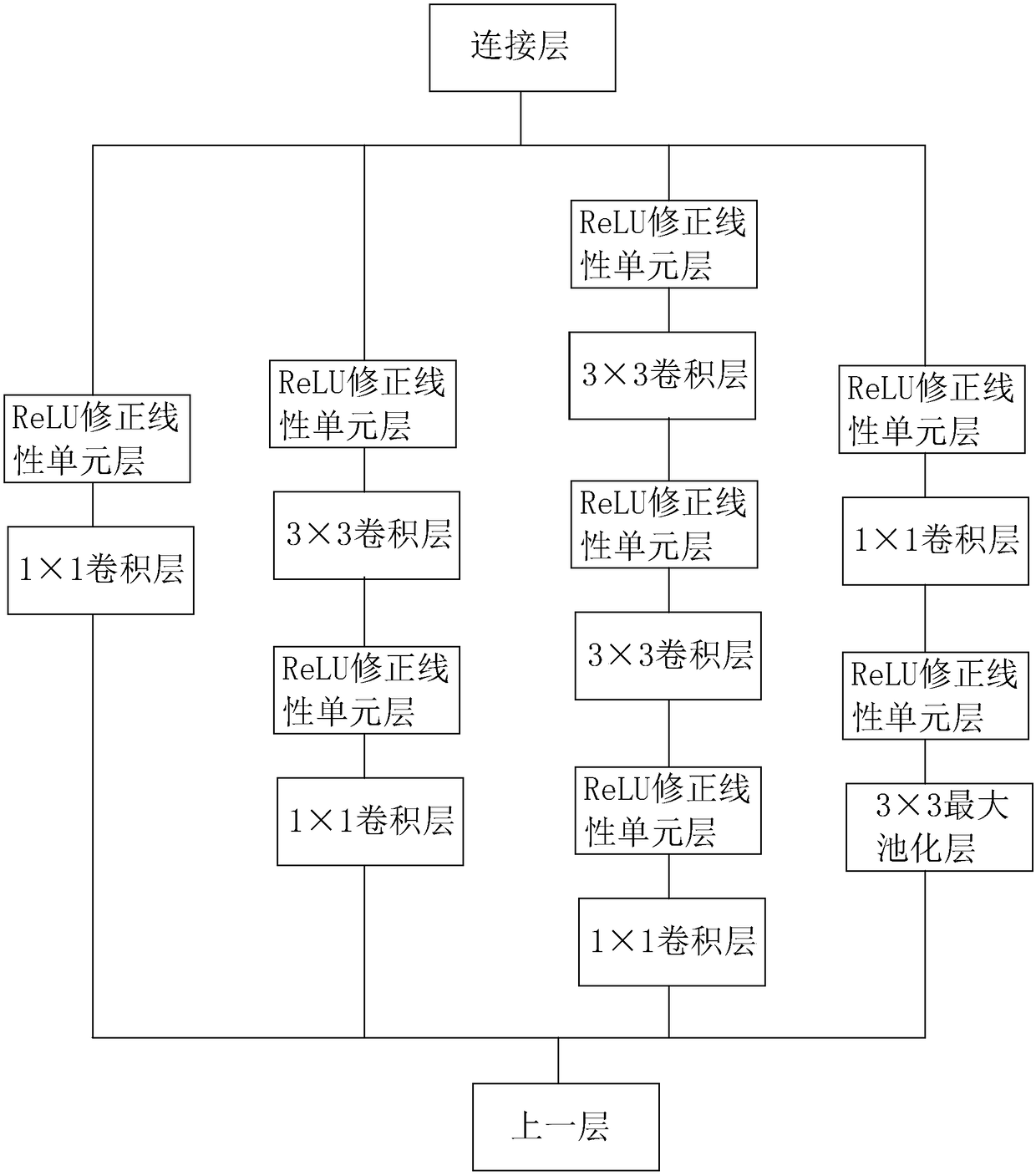

[0038] C. Construct a convolutional neural network with a multi-scale parallel training structure;

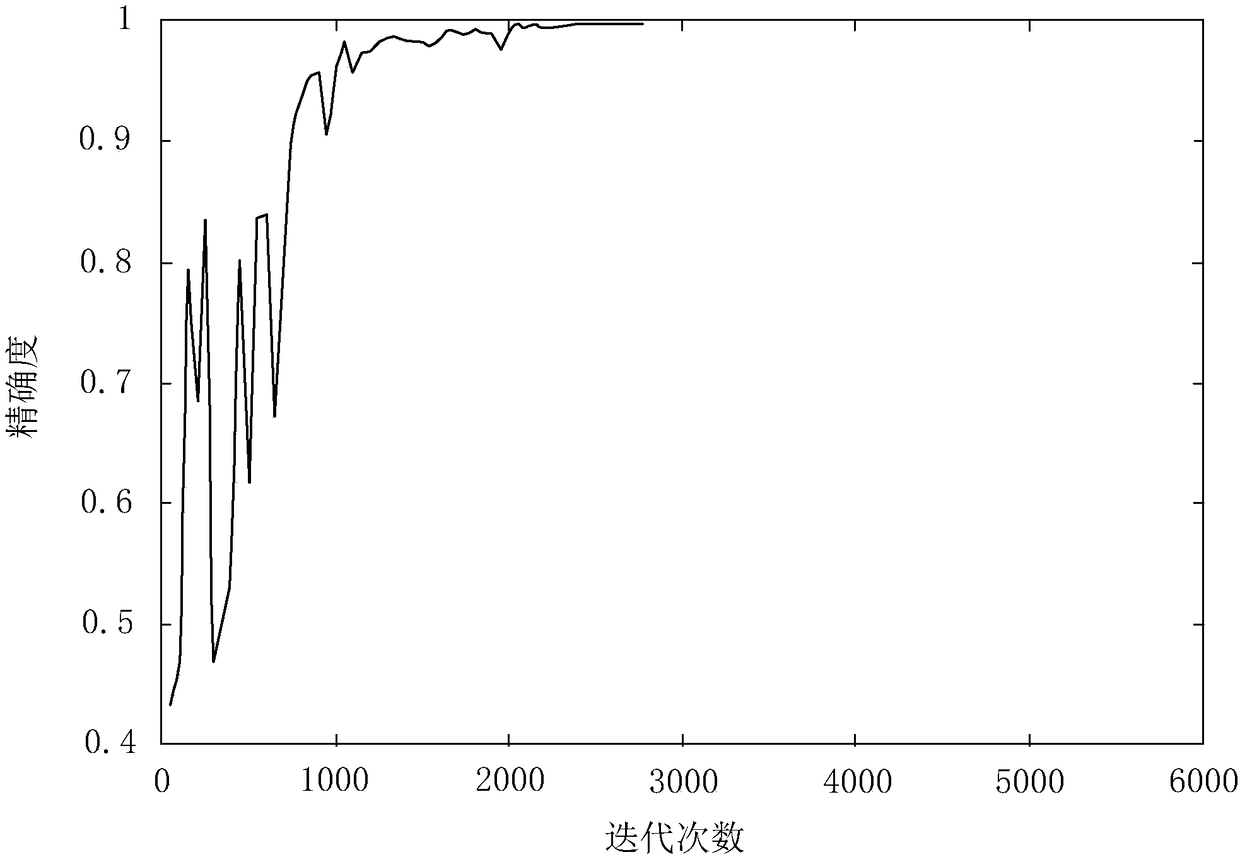

[0039] D. Use the training pictures to train the convolutional neural network;

[0040] E. Use the trained and processed convolutional neural network for fault detection.

[0041] Wherein, in step A, the image acquisition and preprocessing to obtain the sample picture include the following steps:

[0042] A1, use the camera to collect the webbing pictures, and carry out binarization processing on the collected webbing pictures;

[0043] A2. Perform tilt correction on the binarized webbing image;

[0044] A3. Cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com