Connection structure for radio frequency coaxial connector and printed circuit board

A printed circuit board, radio frequency coaxial technology, applied in the direction of circuit, connection, fixed connection, etc., can solve the problems of cumbersome assembly process and difficult replacement of components, and achieve the effect of reducing damage, convenient disassembly and assembly, and accurate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

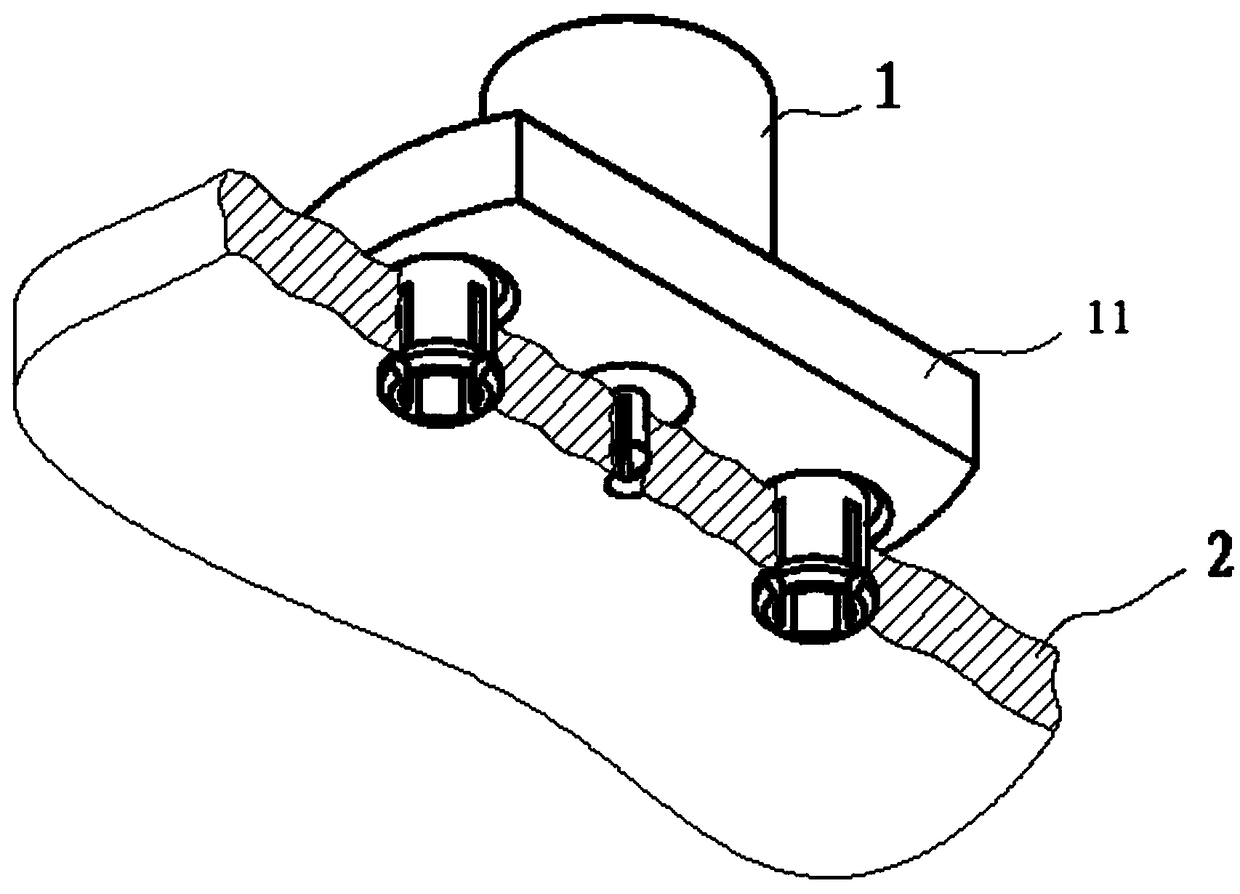

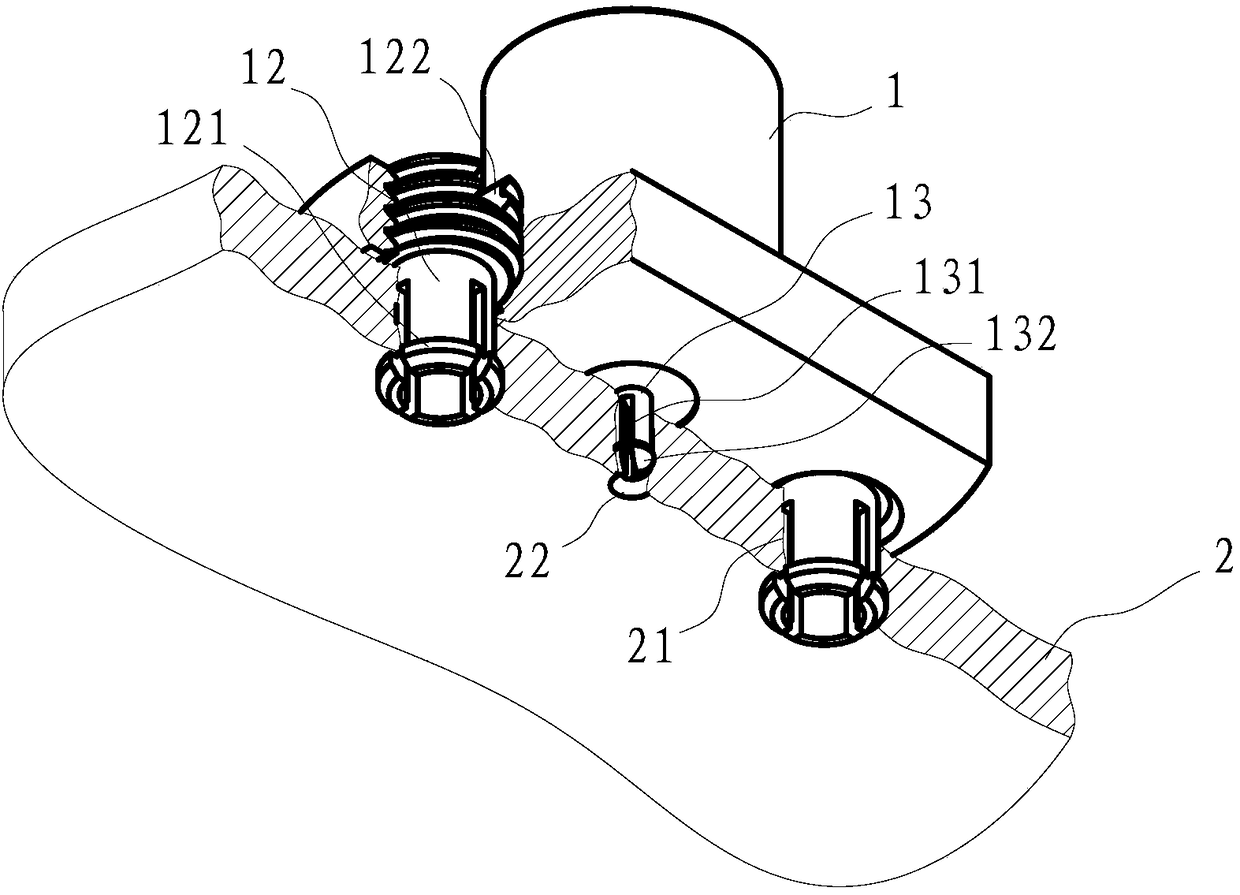

[0032] Such as Figure 2 to Figure 5 In the shown embodiment, the number of positioning connectors is two, and the axial projections of the two positioning connectors 12 and the contact pins 13 are arranged on the same straight line, and the contact pins 13 are located in the middle of the two positioning connectors 12 .

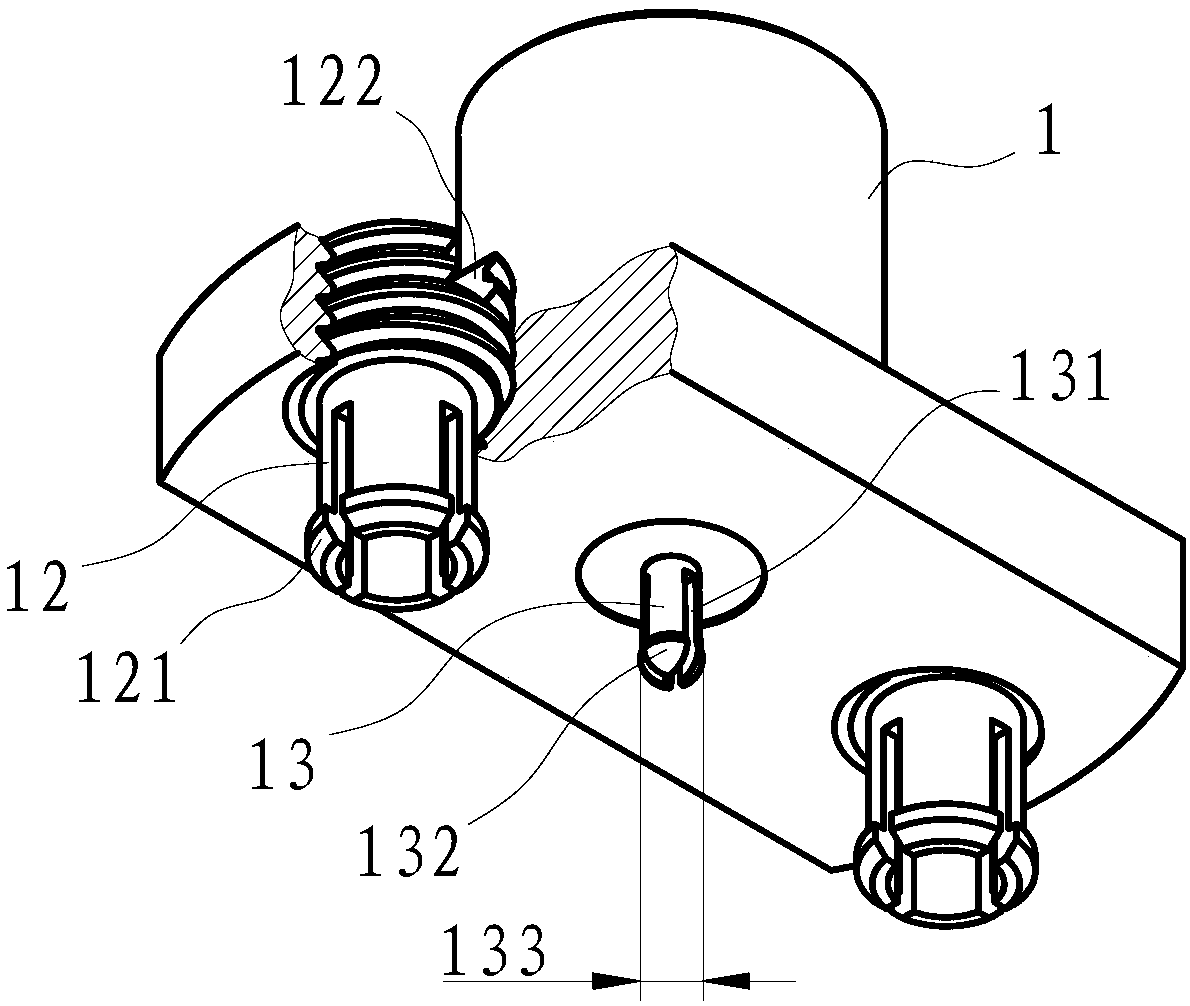

[0033] Such as figure 2 with image 3 One end of the positioning connector 12 is threadedly connected to the contact piece 11, and the other end is clamped to the printed board 2 by a circlip, and the printed board 2 is provided with a clamping hole 21 for the circlip to pass through;

[0034] Such as Figure 4 The circlip of the positioning connector 12 is a hollow cylinder, and its circumference is provided with a plurality of grooves along the axial direction of the locating connector, so that the circlip can be elastically compressed in the radial direction.

[0035] A slot or a cross groove 122 is provided on one end surface of the positioning conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com