A new ultra-light and ultra-quiet driver

A driver, ultra-light technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of low efficiency, heavy weight, high noise, and achieve the effect of shortening the time of the expansion and contraction process, high practicability, and novel methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

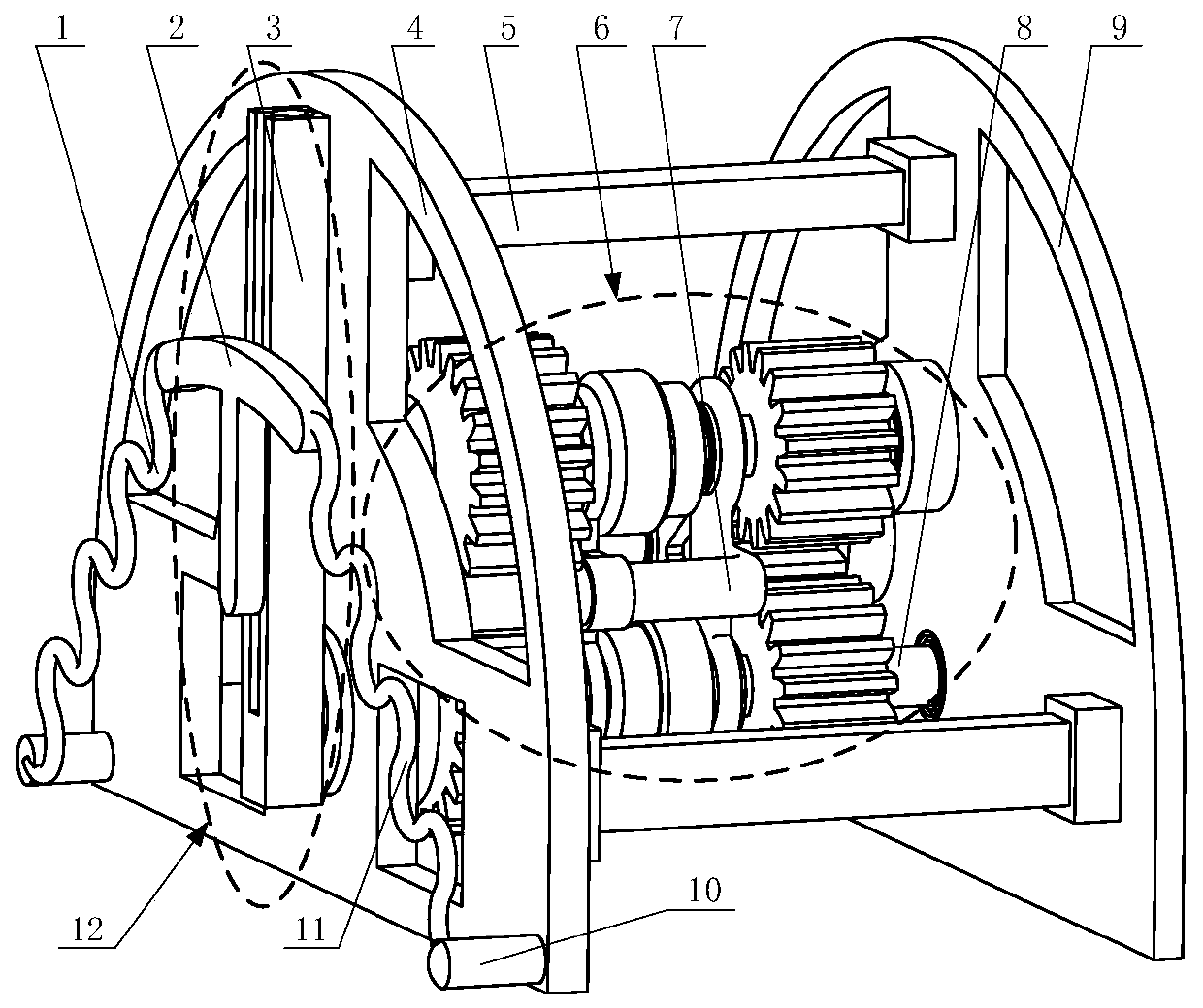

[0052] Figure 1a One embodiment of the invention is shown in the form of:

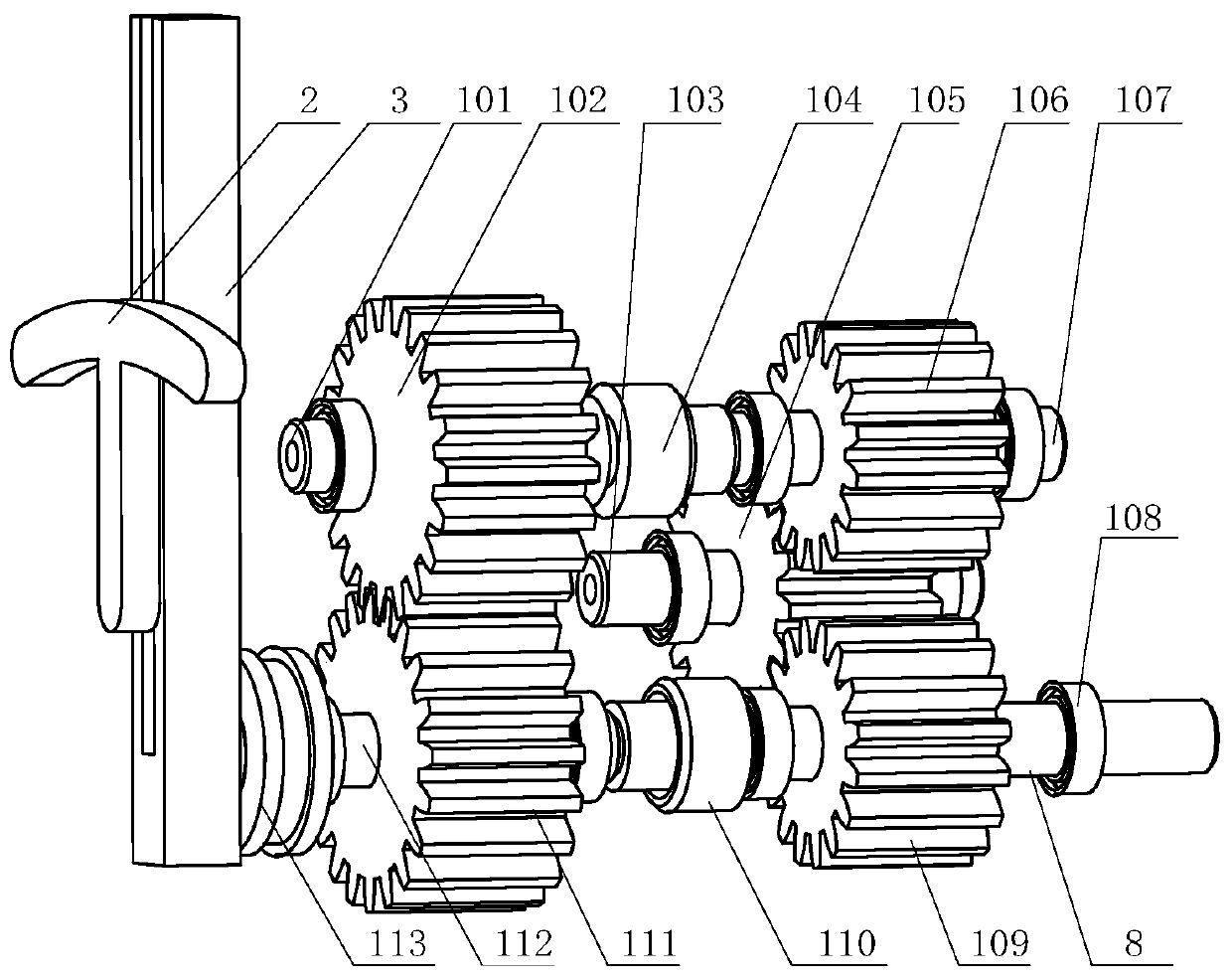

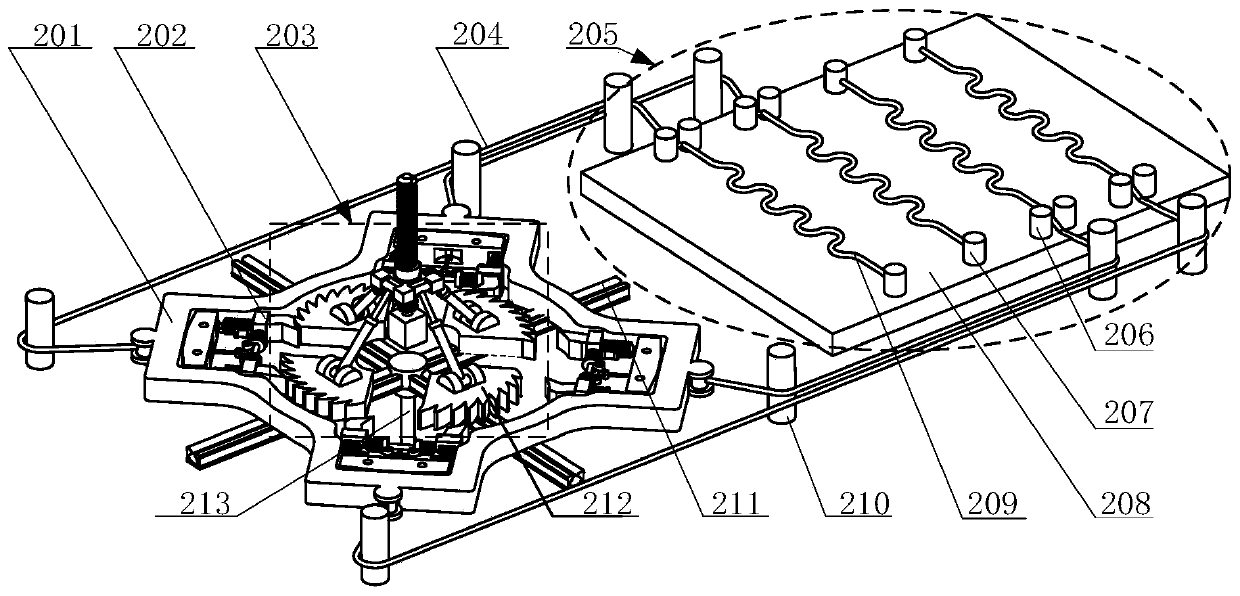

[0053] The basic mechanical structure of the new ultra-light silent driver is composed of a power generating mechanism, a "T"-shaped swing mechanism 12, and a movement direction maintaining mechanism 6. The power generating mechanism is composed of a shape memory alloy driving wire I 1 and a shape memory alloy driving wire II 11 And its corresponding control electrode 10 composition, based on the "memory" effect of SMA, when the shape memory alloy driving wire is heated and cooled by a certain frequency through the control electrode 10, the shape of the wire changes and stretches and contracts periodically, while the shape One end of the memory alloy drive wire is connected to the control electrode 10, and the other end is connected to the two lugs of the slider 2 respectively, so as to control the shape memory alloy drive wire I and II to elongate and contract alternately, so as to pull the slider 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com