Filtration monitoring systems

A monitoring system and filtration system technology, applied in filtration separation, charging system, dispersed particle filtration, etc., can solve problems such as damage to the engine, different replacement cycles of the filtration system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

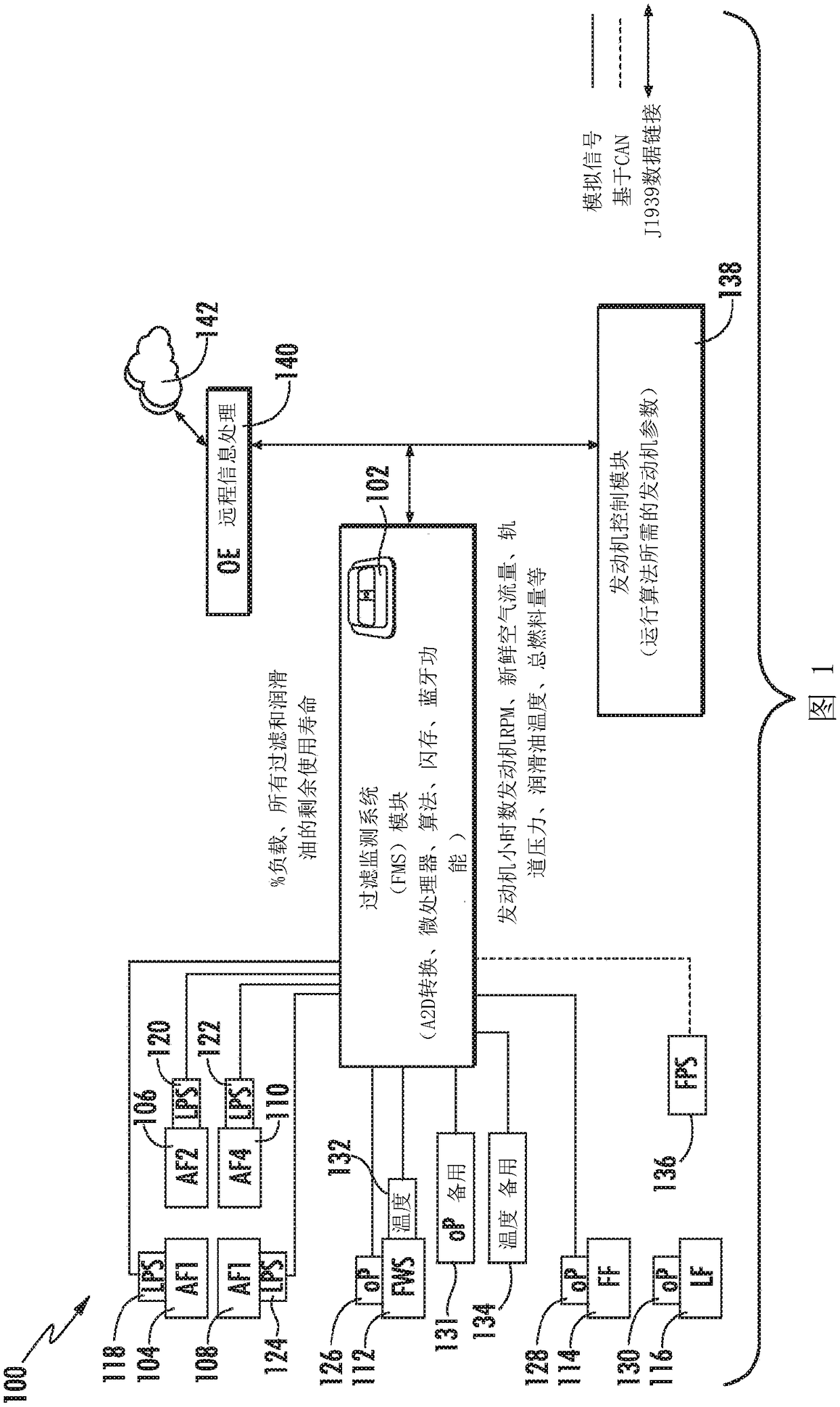

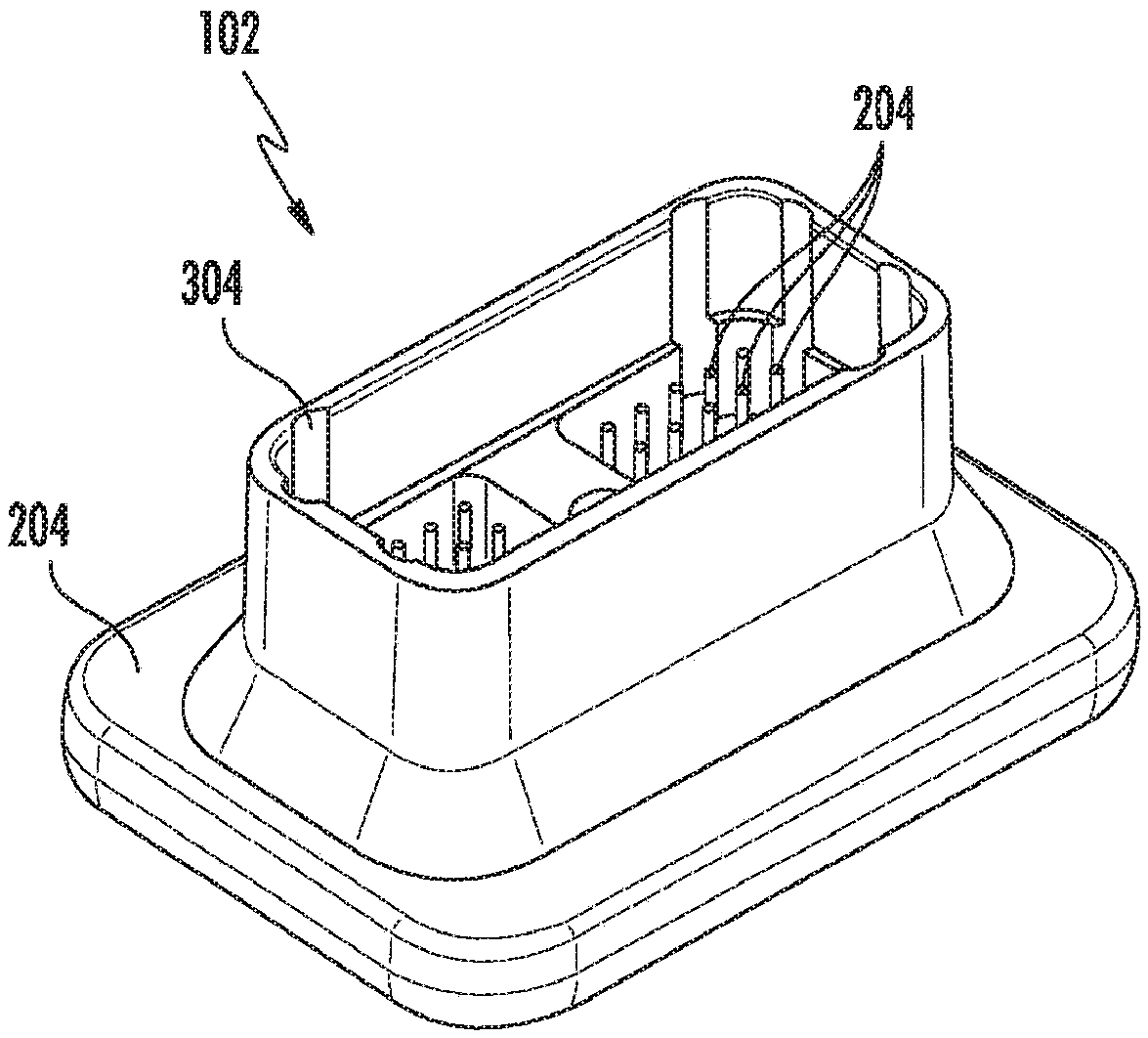

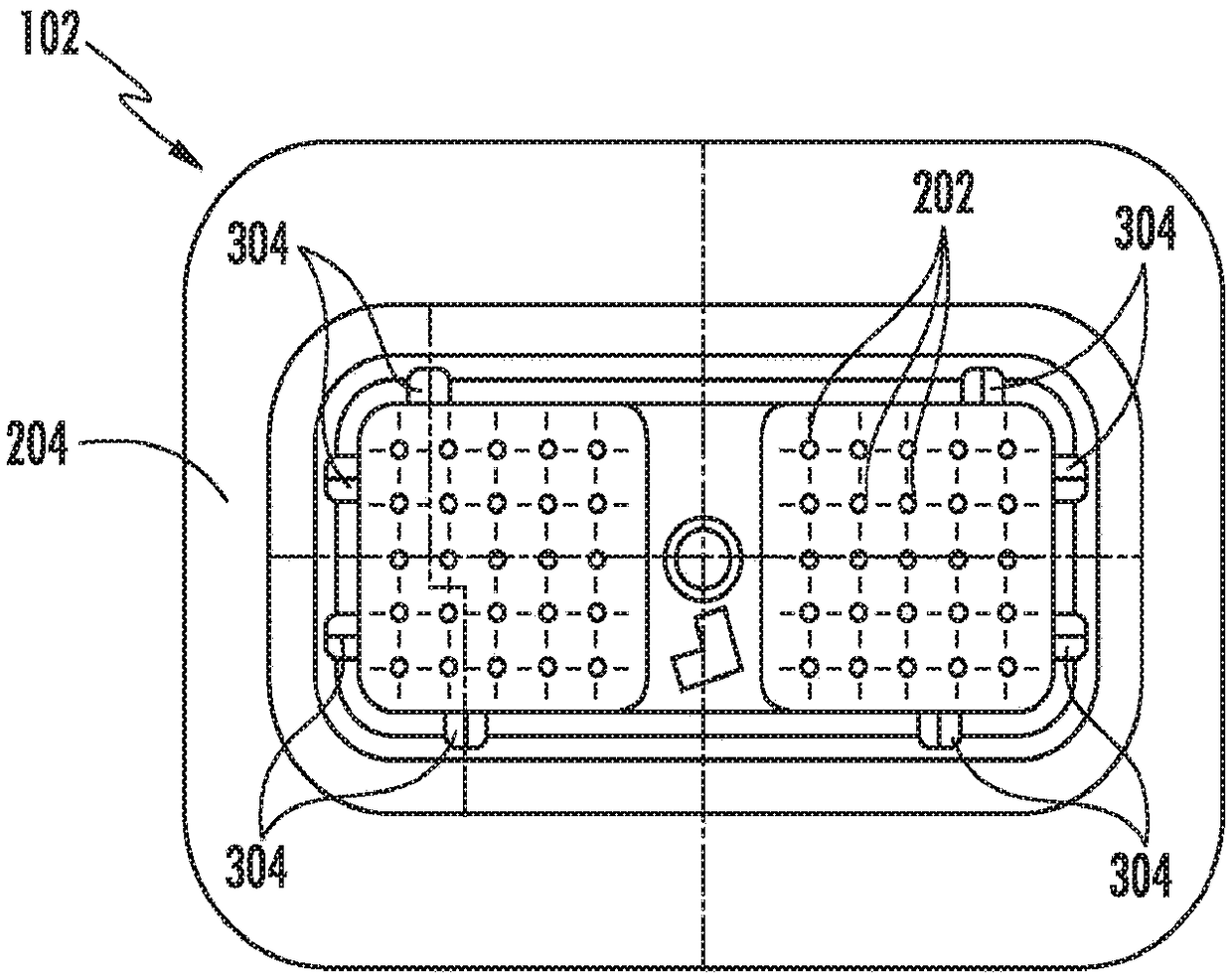

[0035] Referring generally to the drawings, a filtration monitoring system is described. A filter monitoring system is an electronic system control module installed on an internal combustion engine or in a vehicle powered by an internal combustion engine. The filtration monitoring system monitors the health and status of the filtration system on the engine. Filtration monitoring systems track filter loading patterns and predict remaining filter life by running intelligent algorithms based on sensor feedback (eg, pressure sensor feedback, differential pressure sensor feedback, fluid quality characteristic sensor feedback, etc.). Monitoring filtration systems and fluids may include fuel-water separator filtration systems, fuel filtration systems, lube oil filtration systems, hydraulic fluid filtration systems, air filtration systems, crankcase ventilation systems, engine oil, cooling fluids, hydraulic oil, air, and any other Any of those fluids associated with filtration system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com