Cutting device used for solid wood floor cutting machine

A cutting device, a technology for solid wood floors, applied in wood processing appliances, forming/shaping machines, special forming/shaping machines, etc., can solve the problem of difficult control of cutting precision, improve cutting precision, cut uniform size, avoid top and bottom bouncing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

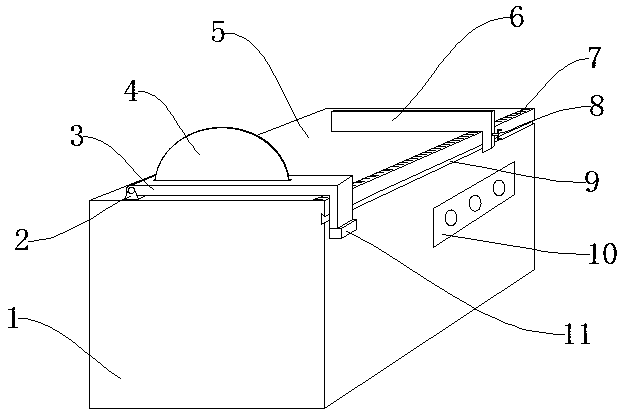

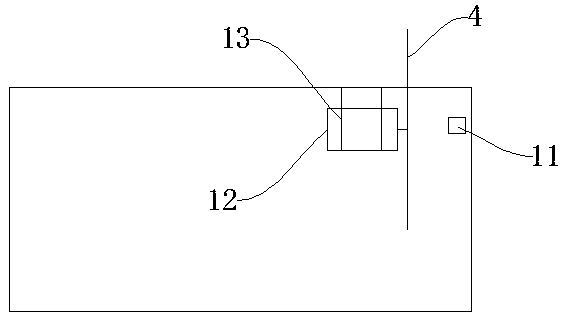

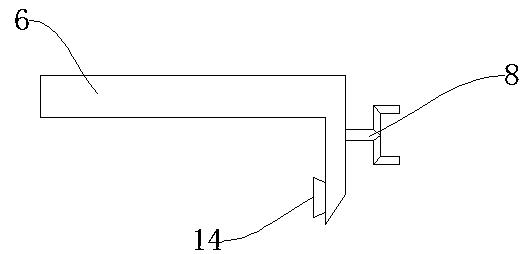

[0020] Such as Figure 1-Figure 3 As shown, a cutting device for a solid wood floor cutting machine includes a body 1, a support 2, and a baffle 6. A bracket 13 is arranged on the top of the body 1, and a servo motor 12 is arranged on the lower part of the bracket 13. One end of the servo motor 12 is arranged There is a cutting piece 4, an electromagnet 11 is arranged on one side of the body 1, a worktable 5 is arranged on the top of the body 1, a scale 7 is arranged on one side edge of the worktable 5, a support 2 is provided at one end of the worktable 5, and a support 2 A pressure plate 3 is arranged on the top, a slideway 9 is arranged on one side of the body 1, a slider 14 is arranged inside the slideway 9, a baffle 6 is arranged at one end of the slider 14, and a locking screw 8 is arranged at one end of the baffle 6, and the side of the body 1 The middle part is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com