Engine piston temperature field remote measurement system calibration testing stand

A remote measurement system and piston temperature technology, applied in thermometer testing/calibration, thermometers, measuring devices, etc., to achieve synchronous calibration of data, convenient and reliable testing methods, and real-time and effective data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

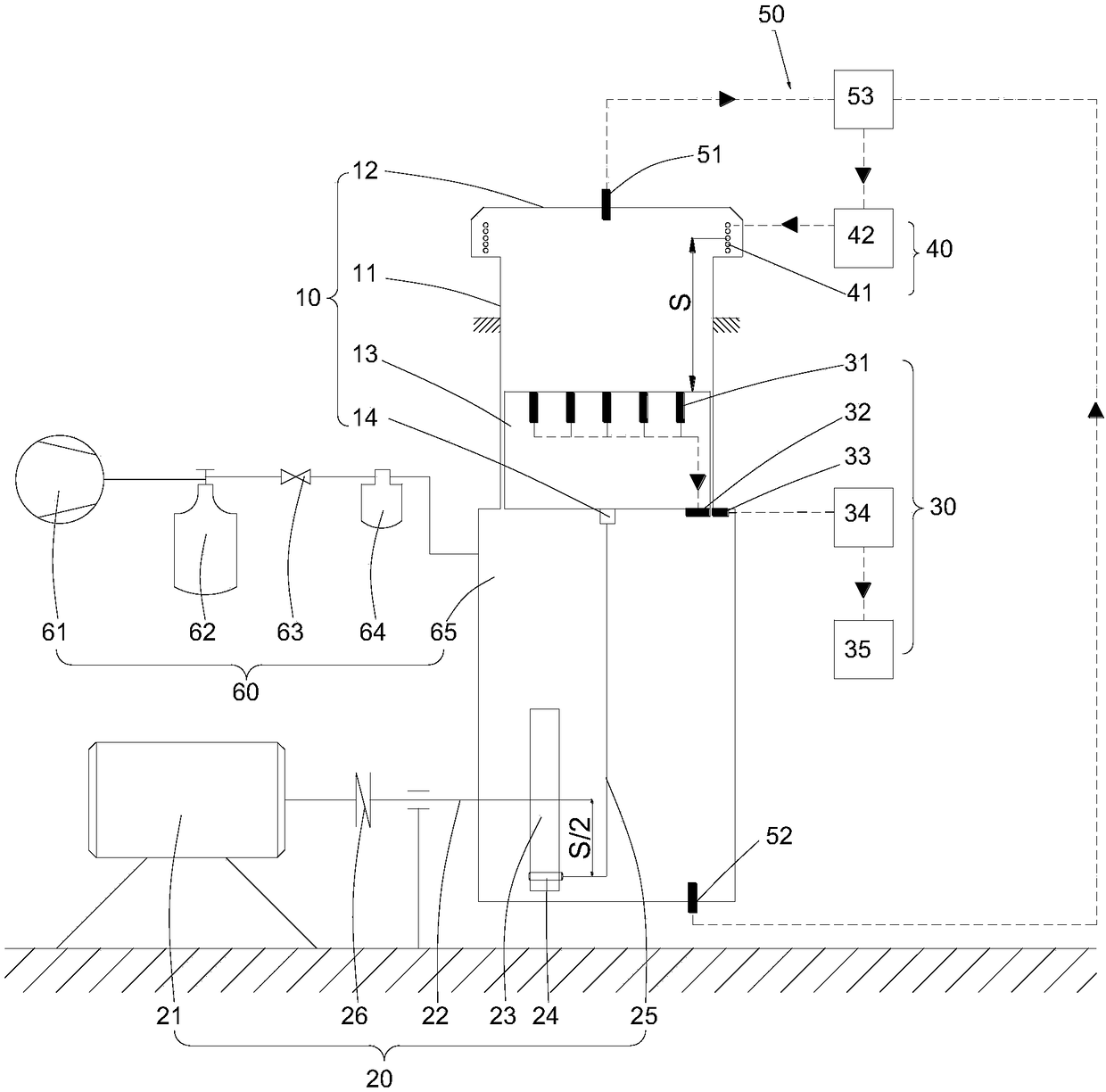

[0030] Such as figure 1 As shown, it is a calibration test bench for the engine piston temperature field telemetry system of a preferred embodiment of the present invention, including:

[0031] The simulation device 10 includes a cylinder liner 11 , a cylinder head 12 and a piston 13 . Piston 13 is the measured object of the test bench of the present invention, and it and cylinder liner 11, cylinder head 12 jointly simulate the relative motion state of engine, and cylinder liner 11, cylinder head 12, piston 13 dimensions can be appropriately simplified and reduced in design and manufacture according to the actual engine , to ensure considerable strength and rigidity.

[0032] The driving mechanism 20 includes a motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com