Vacuum cleaner suction head or floor suction head detection line and detection operation method thereof

A detection line and vacuum cleaner technology, applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve the problems of high cost of product testing and control, low testing efficiency, etc., to reduce manual operation management costs, reduce product The effect of detection cost, control stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

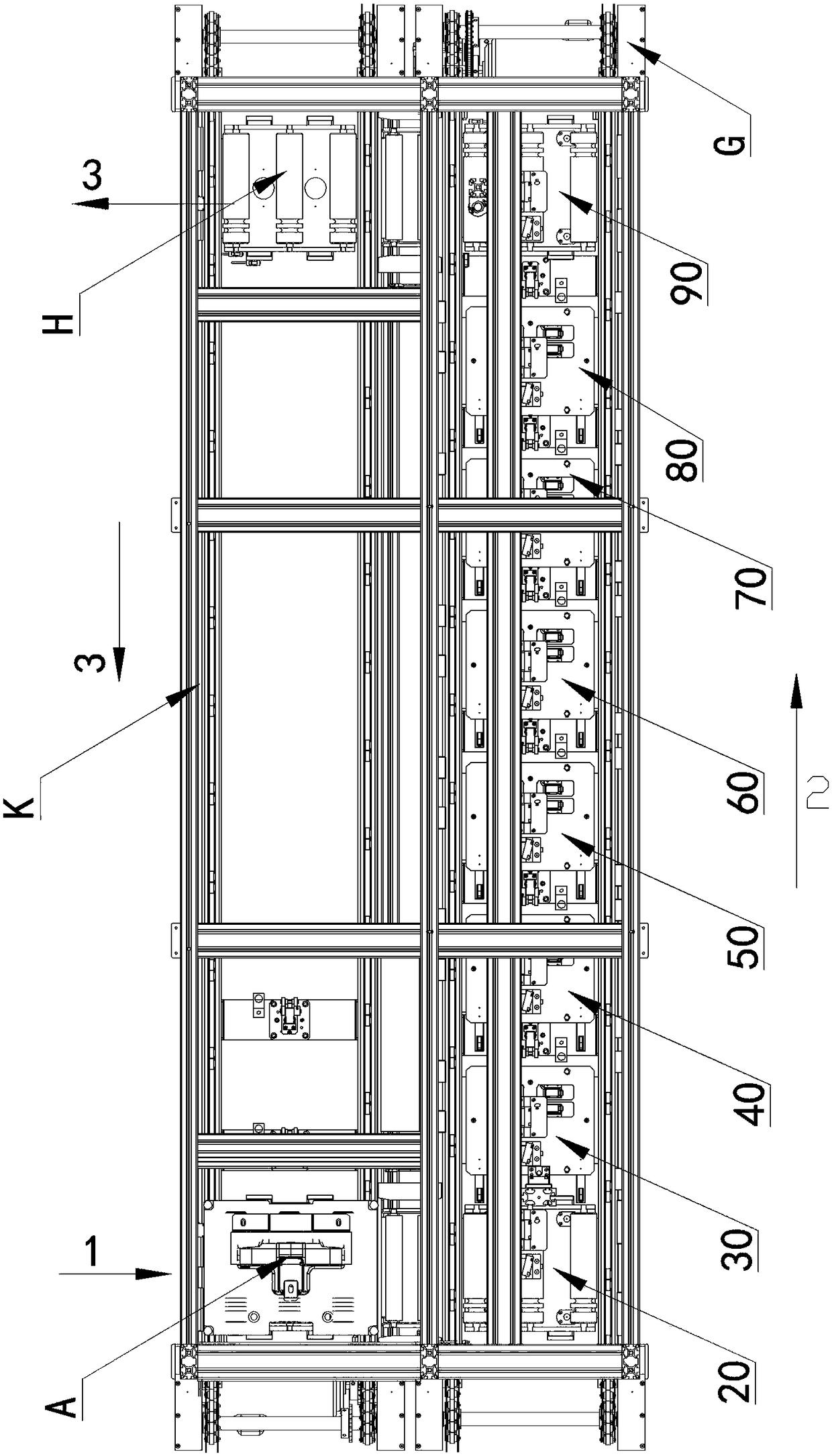

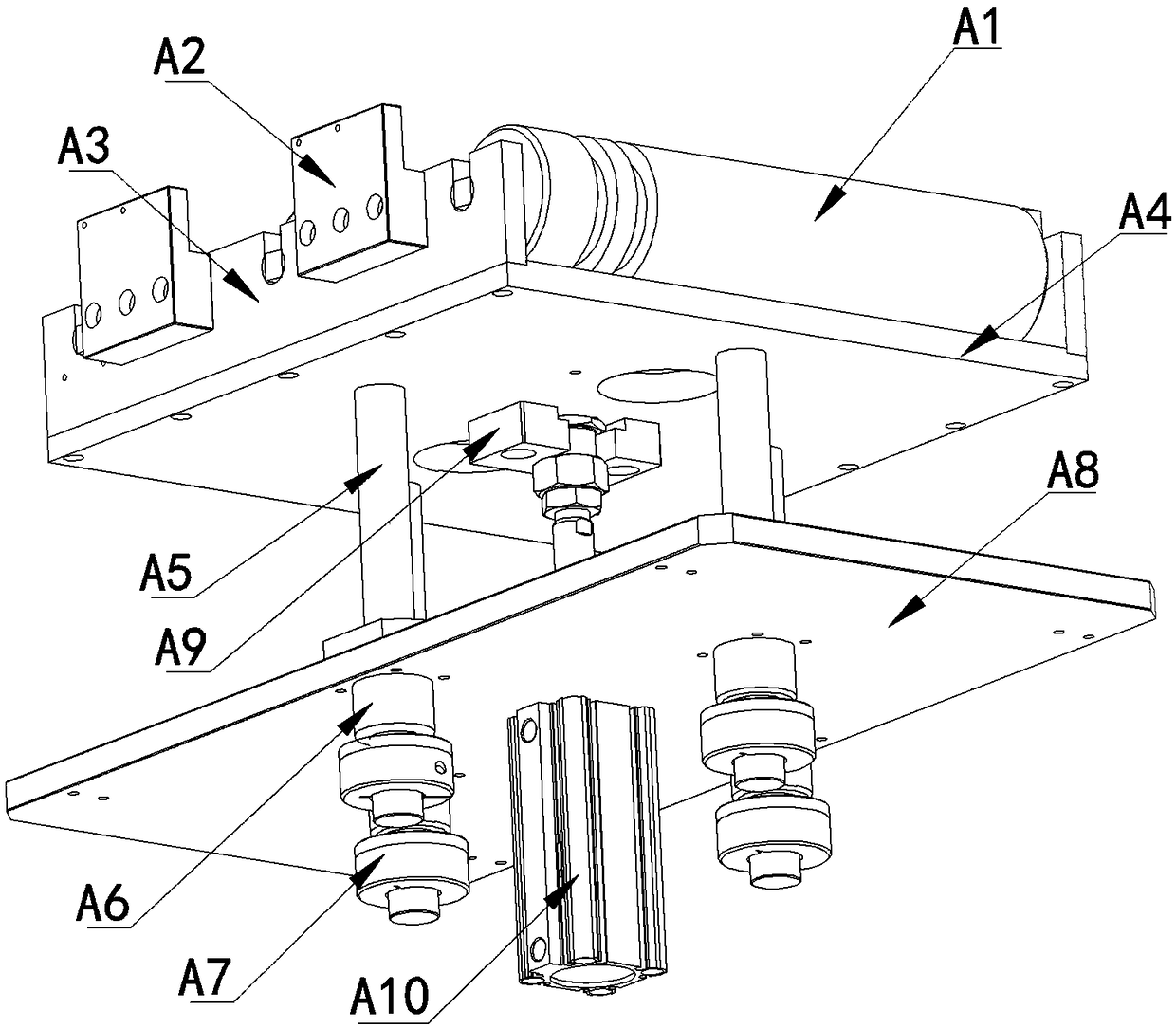

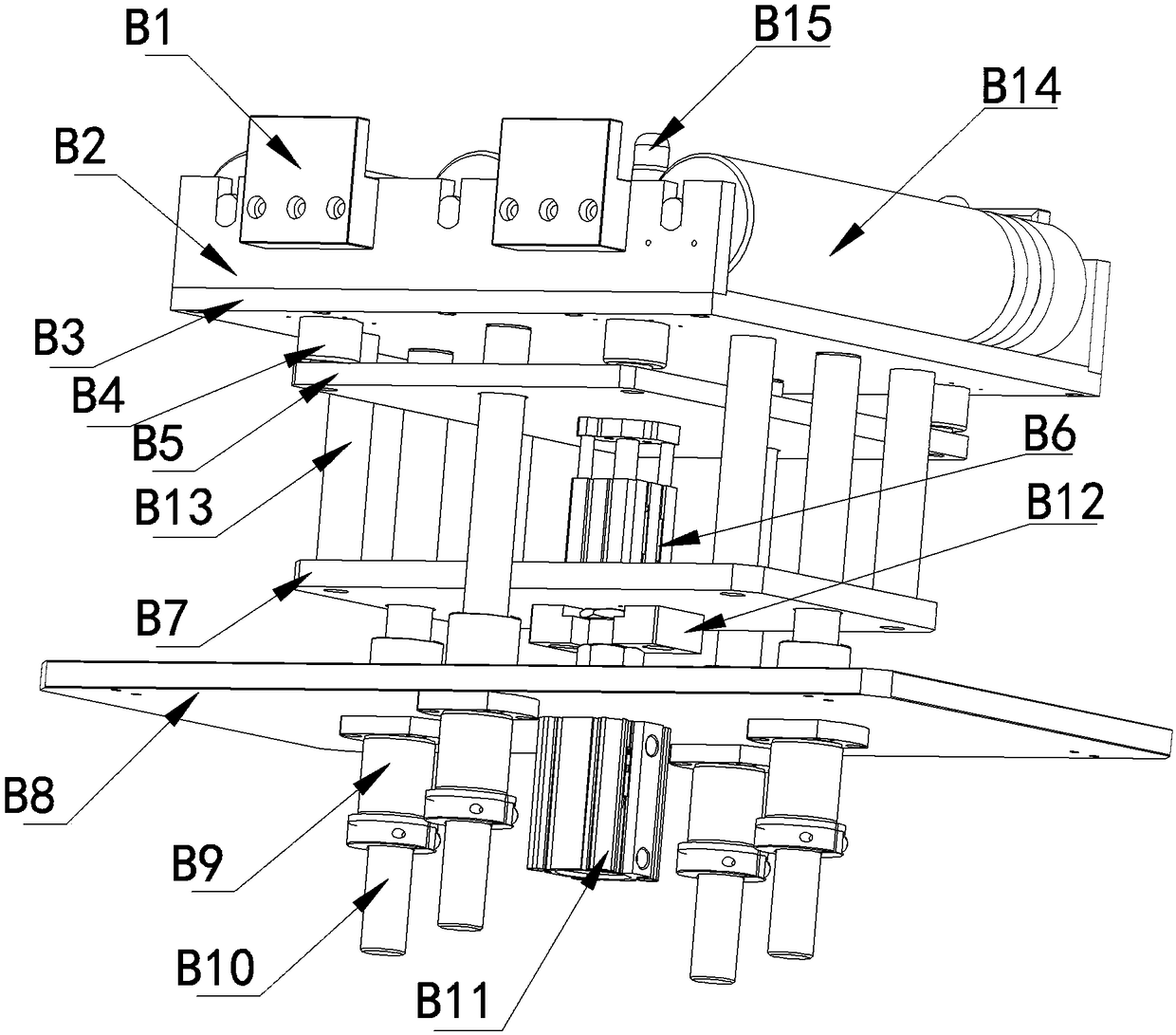

[0030] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 In the shown embodiment, a vacuum cleaner nozzle or floor nozzle detection line includes a detection line frame K, and also includes a discharge mechanism A, a power drive mechanism G, and a discharge mechanism H arranged on the detection line frame. , the sequentially arranged multi-stage top preheating mechanism and the sequentially arranged multi-stage top detection mechanism, the multi-stage top detection mechanism is set at the rear stage of the multi-stage top preheating mechanism, and each stage of the top preheating mechanism is equipped with a detection roller mechanism and One or more detection tools, the one or more detection tools include the first intermediate detection tool, the second intermediate detection tool and the LED detection tool, the multi-stage top detection mechanism includes a top mechanism and a detection mechanism, and the detection mechanism T...

Embodiment 2

[0032] A method for detecting and manipulating a suction head of a vacuum cleaner or a detection line of a floor suction head, comprising the following steps:

[0033] a. Before starting the vacuum cleaner suction head or floor suction head detection line of embodiment 1, adjust the corresponding detection station according to the different suction head products to be detected, the first intermediate detection tooling of embodiment 1 can be driven by the first detection traverse The cylinder and the first detection vertical movement drive the cylinder to move to adjust, and the second intermediate detection tool of embodiment 1 adjusts the position of the probe by adjusting the pin and the positioning block;

[0034] b. Start the detection line, put in the suction head product, and the suction head product enters the multi-stage upper-top preheating mechanism of embodiment 1 through the drive of the electric drum. According to the different suction head products, different dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com