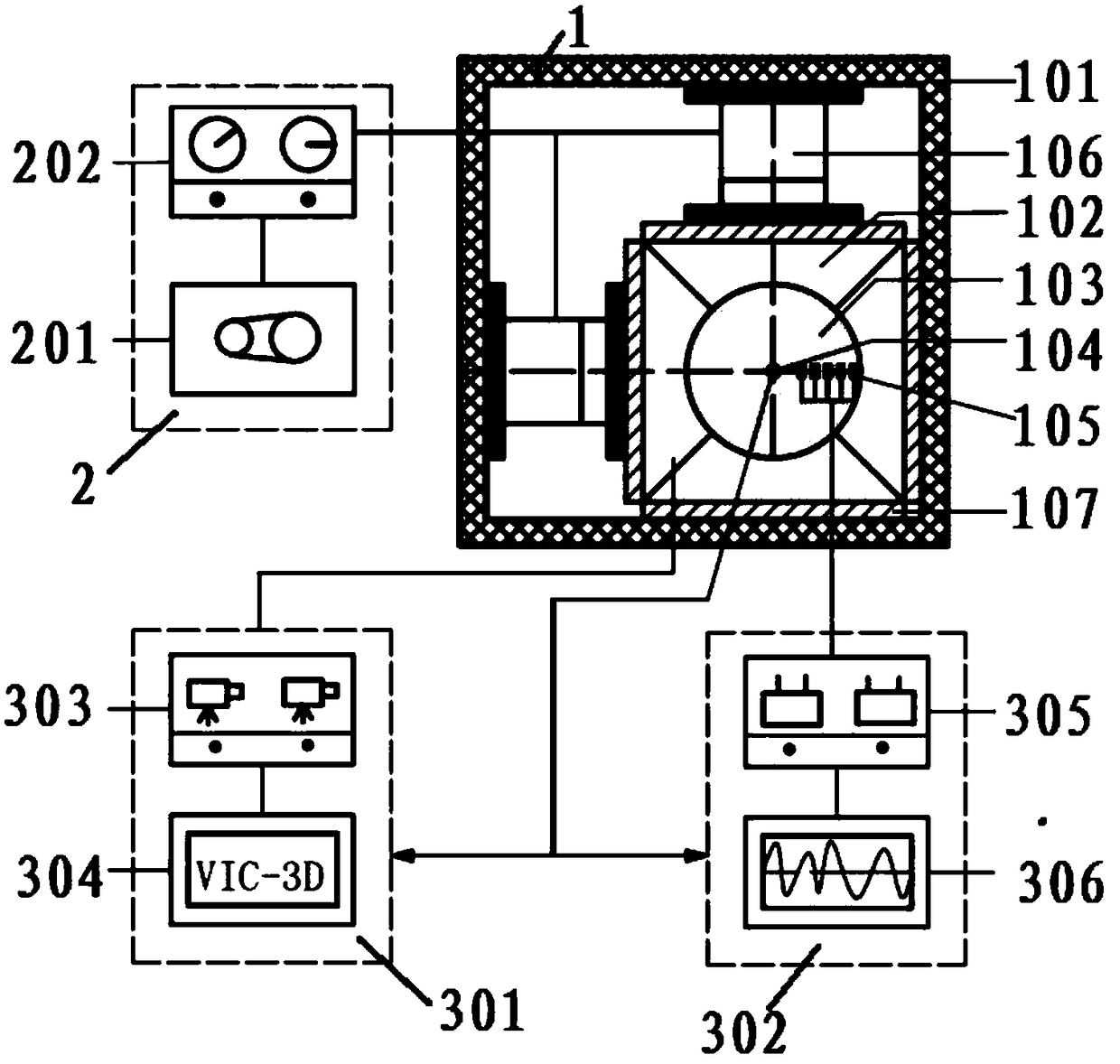

Driving dynamic-static loading experimental device for confining pressure and explosion

A technology for loading experiments and experimental devices, which is applied to measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve problems such as the inability to accurately analyze the dynamic structure relationship and failure characteristics of rock materials, and achieve uniform pressure , The effect of eliminating interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

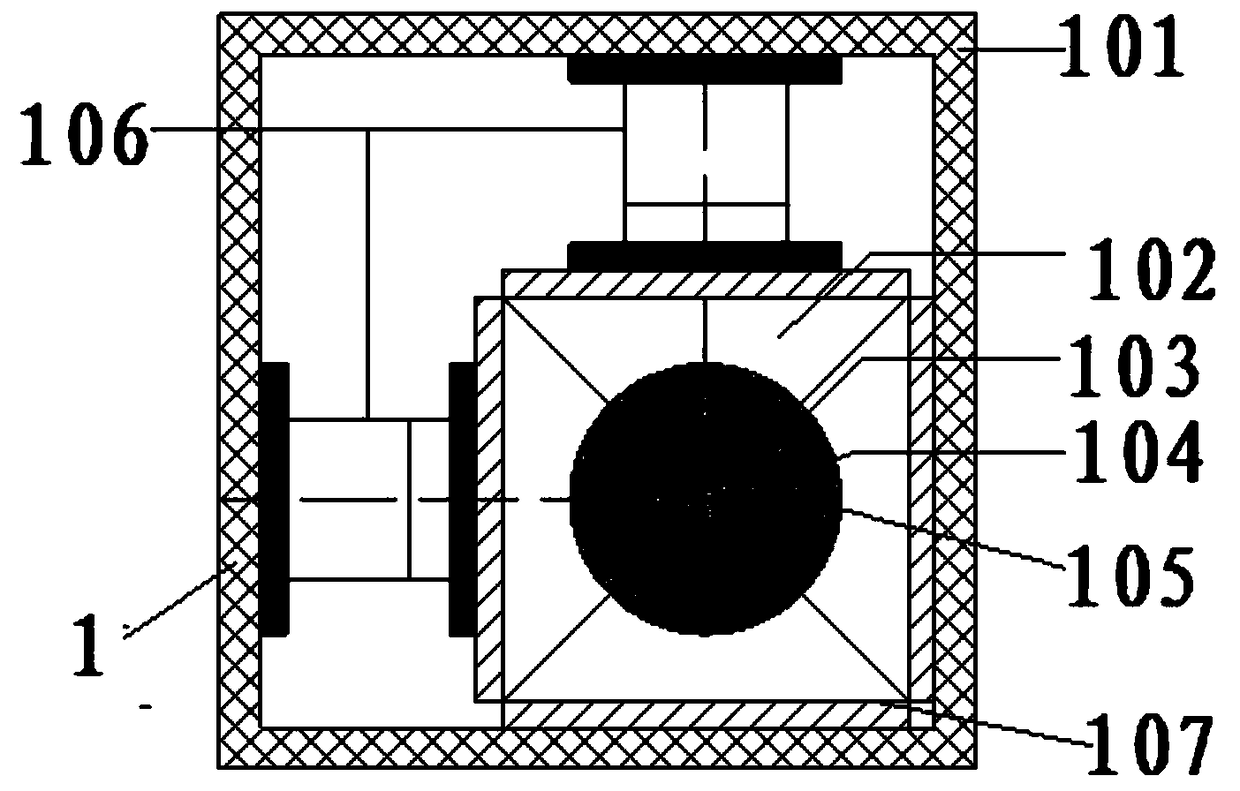

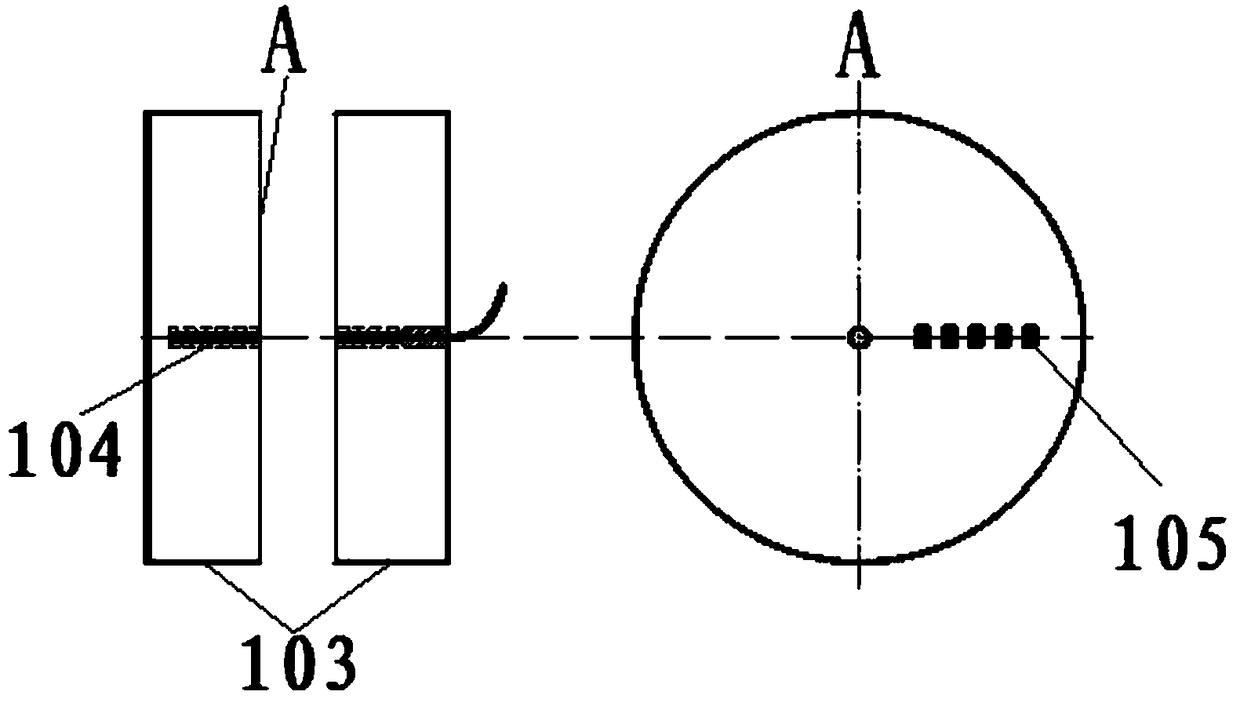

[0027] In actual operation, the built-in sensor is placed inside the test piece 103 . When making the test piece 103, each set of test pieces consists of two pieces, A and B, and A is the research object, and DIC and strain tests are performed on both ends of A. On the end face of the strain gauge test, in order to eliminate the tensile effect of the axially reflected wave, the B piece is used to closely fit the test end face, and at the same time, mark points are processed on the DIC test face (the position corresponds to the strain gauge). Four wedges are used to fix the relative position of the specimen. For easy operation, the high-pressure oil pump can be manually operated as needed. For each jack, a pressure calibration must be performed prior to the experiment. Usually the oil pressure gauge is used to measure the pressure, which is installed on the oil separator. By installing a pressure sensor in front of the jack piston head, the actual pressure of the jack can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com