Test method for acquiring aluminum alloy plate friction-stir welding head fatigue small crack initiation and extension morphology

A friction stir, small crack technology, applied in the field of mechanical structure fatigue, can solve the problem of difficult to obtain reliable online means, achieve the effect of accurate acquisition, improve work efficiency, and improve test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

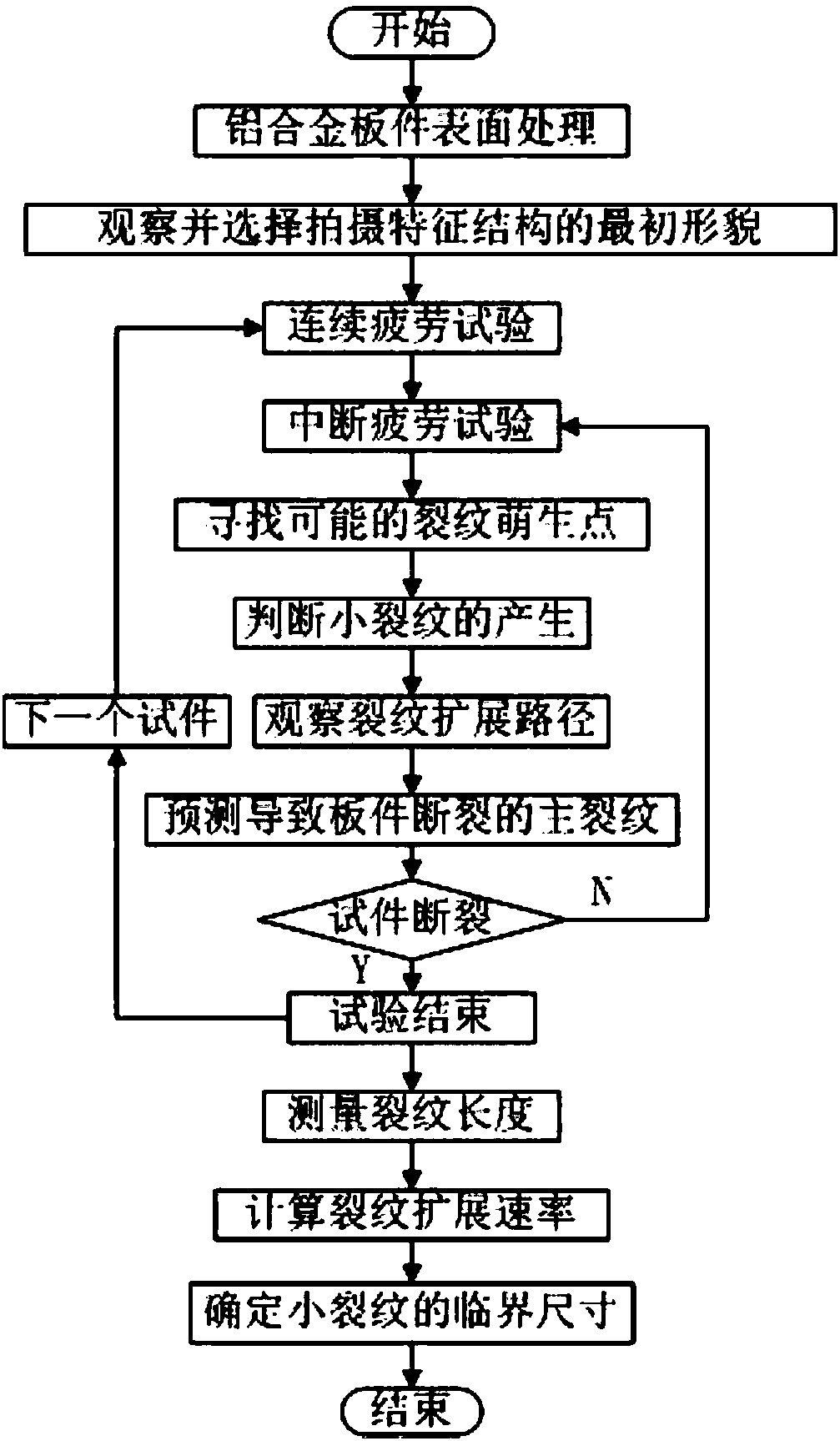

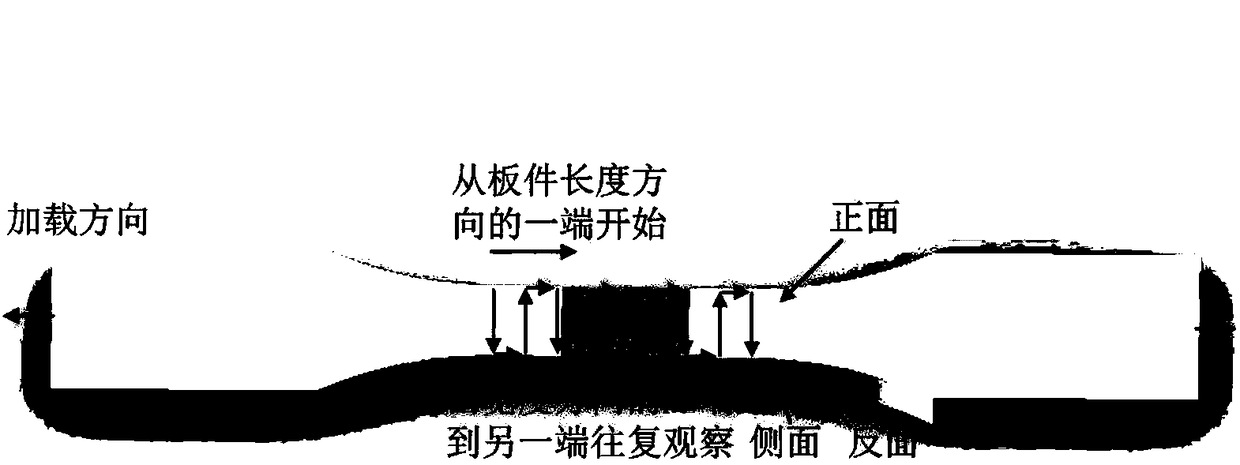

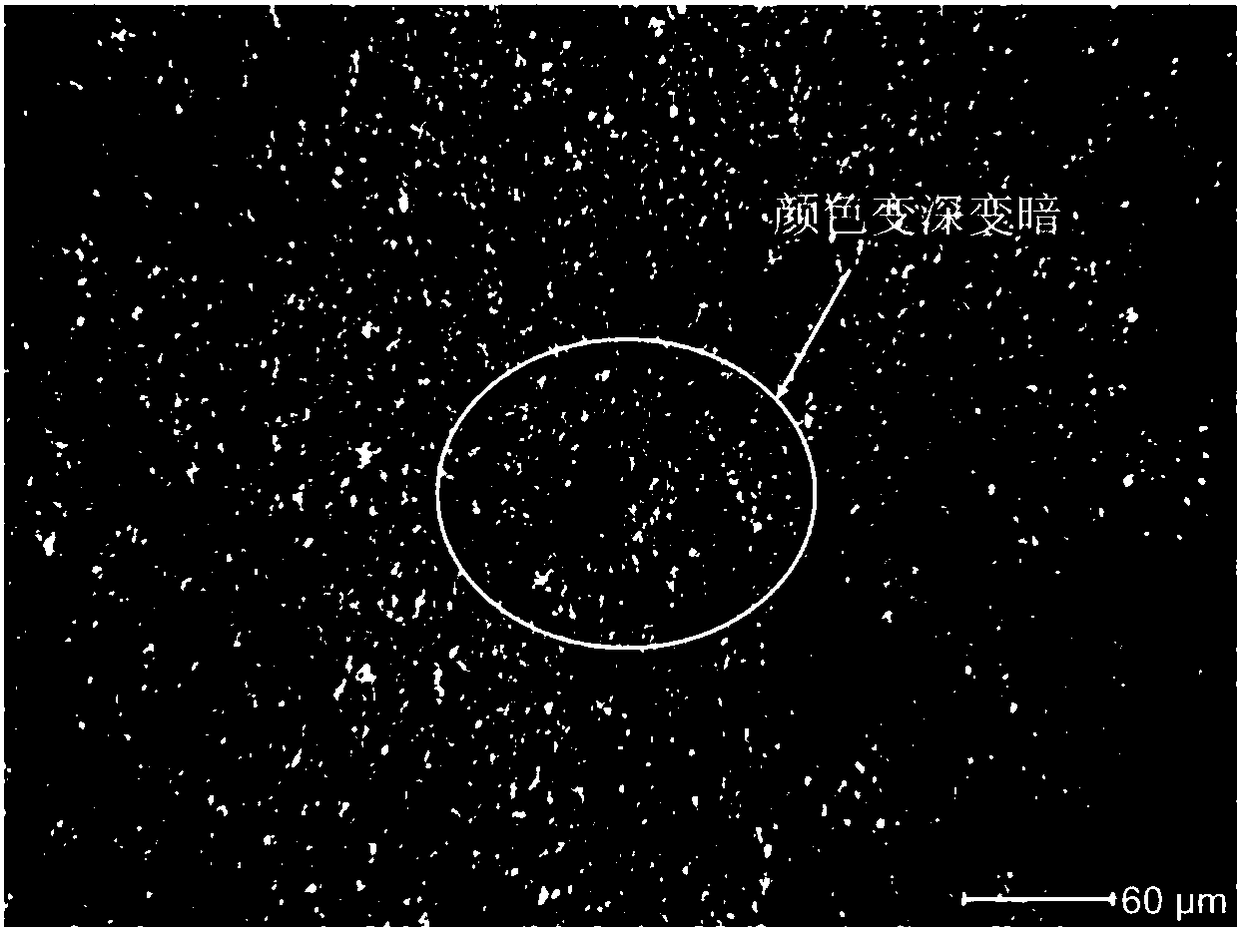

[0033] refer to Figure 1 to Figure 3 , an experimental method for obtaining the initiation and propagation of fatigue small cracks in friction stir welded joints of aluminum alloy plates, the steps of which are as follows:

[0034]Step (1): Surface treatment is carried out on the aluminum alloy plates for continuous fatigue and interrupted fatigue tests obtained by friction stir welding and wire cutting with the same welding parameters. The specific steps are as follows:

[0035] (1.1) First use sandpaper to manually polish the left and right sides of the board, and then use sandpaper to polish the front and back of the board on the grinding and polishing machine. The sandpaper models used are 400#, 800#, 1200#, 2000#, 3000#, 4000#. Every time a sandpaper is replaced, the grinding direction is 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com