Experimental device and method based on characteristic study of metal particle movvement

A technology of metal particles and motion characteristics, applied in the direction of using optical methods to test, test dielectric strength, analyze materials, etc., can solve the problems of gas decomposition, increase the difficulty of detection and prevention, and decrease the dielectric strength, reduce investment, Low performance requirements and the effect of avoiding measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

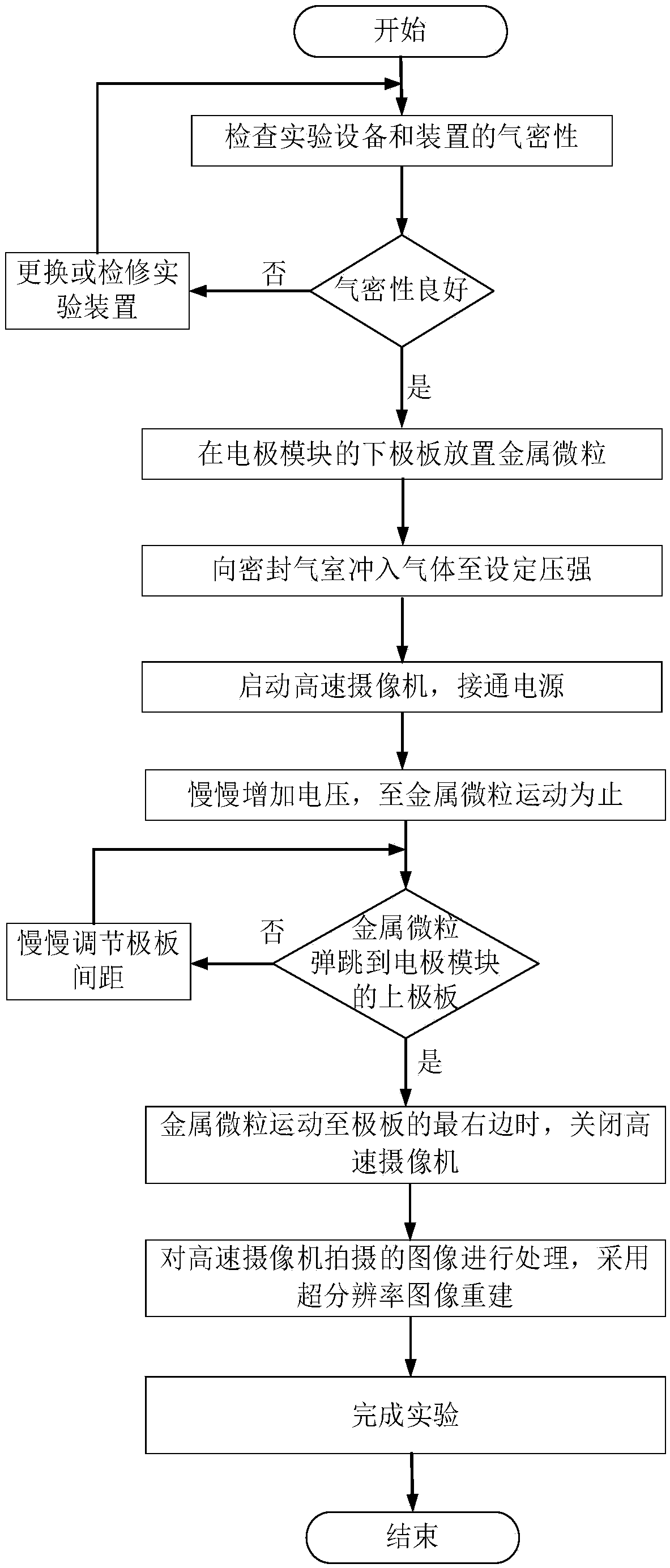

[0031] The technical solutions of the present invention will be described in detail below in conjunction with specific implementation methods.

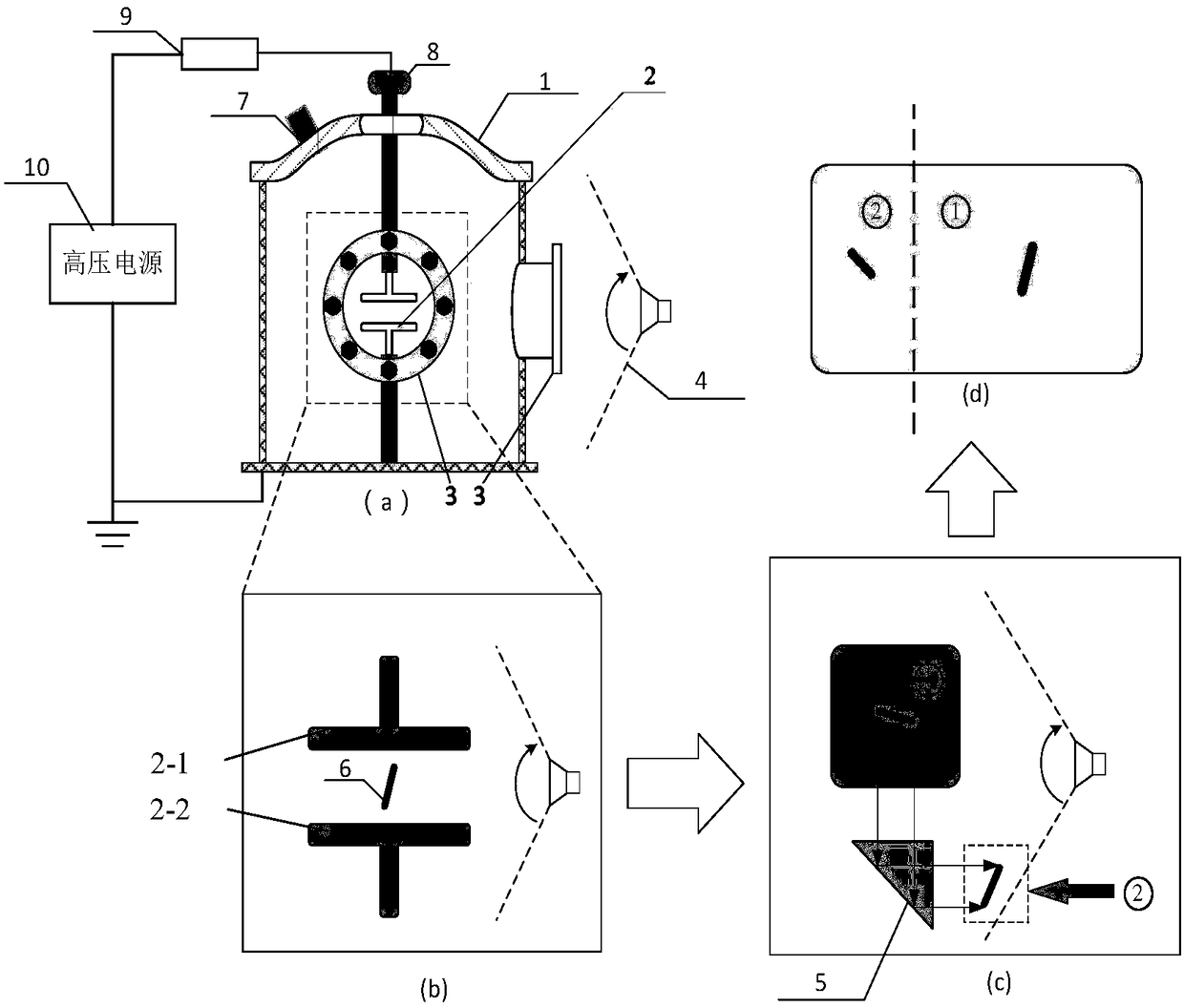

[0032] This embodiment provides a figure 1 The experimental device based on the research on the motion characteristics of metal particles shown in (a) to (d) includes a sealed gas chamber 1 and an electrode module 2; the electrode module 2 is installed inside the sealed gas chamber 1, and the electrode module 2 consists of an upper plate 2-1 and the lower pole plate 2-2, the upper pole plate 2-1 is connected with the high-voltage power supply 10 through the protection resistor 9, the lower pole plate 2-2 is connected with the shell of the sealed air chamber 1, and the shell is grounded. The upper pole plate 2-1 and the lower pole plate 2-2 are arranged in parallel or at an included angle.

[0033] Quartz windows 3 are respectively installed on the front and sides of the sealed gas chamber 1, which are respectively aligned with the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com