Rectifying tower liquid level-flow rate intelligent nonlinear region control method combined with expert system

A nonlinear region, expert system technology, applied in the field of nonlinear region control, to achieve the effect of accurate control data

- Summary

- Abstract

- Description

- Claims

- Application Information

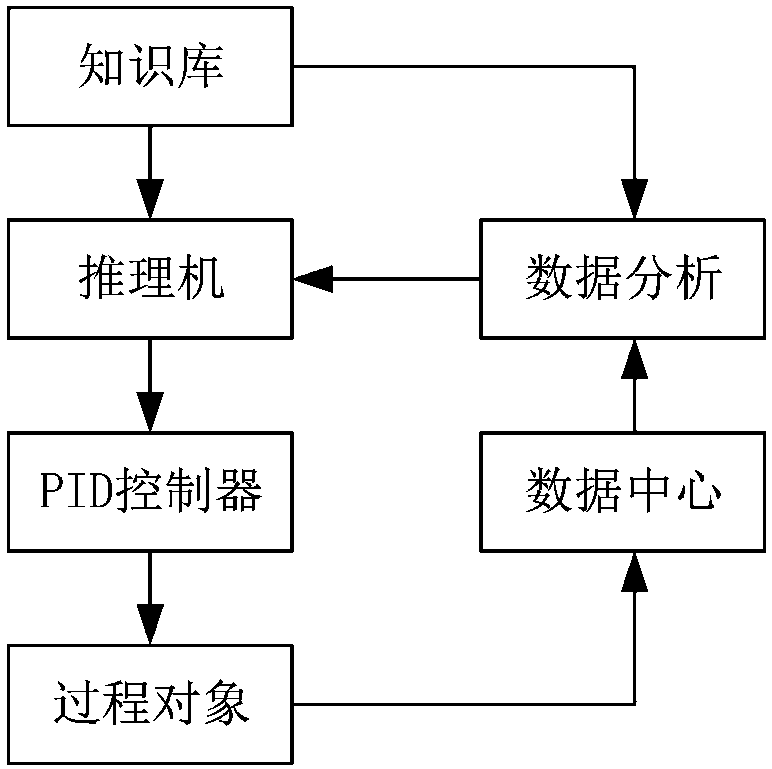

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Aiming at the method proposed by the present invention, it will be described below in conjunction with an example.

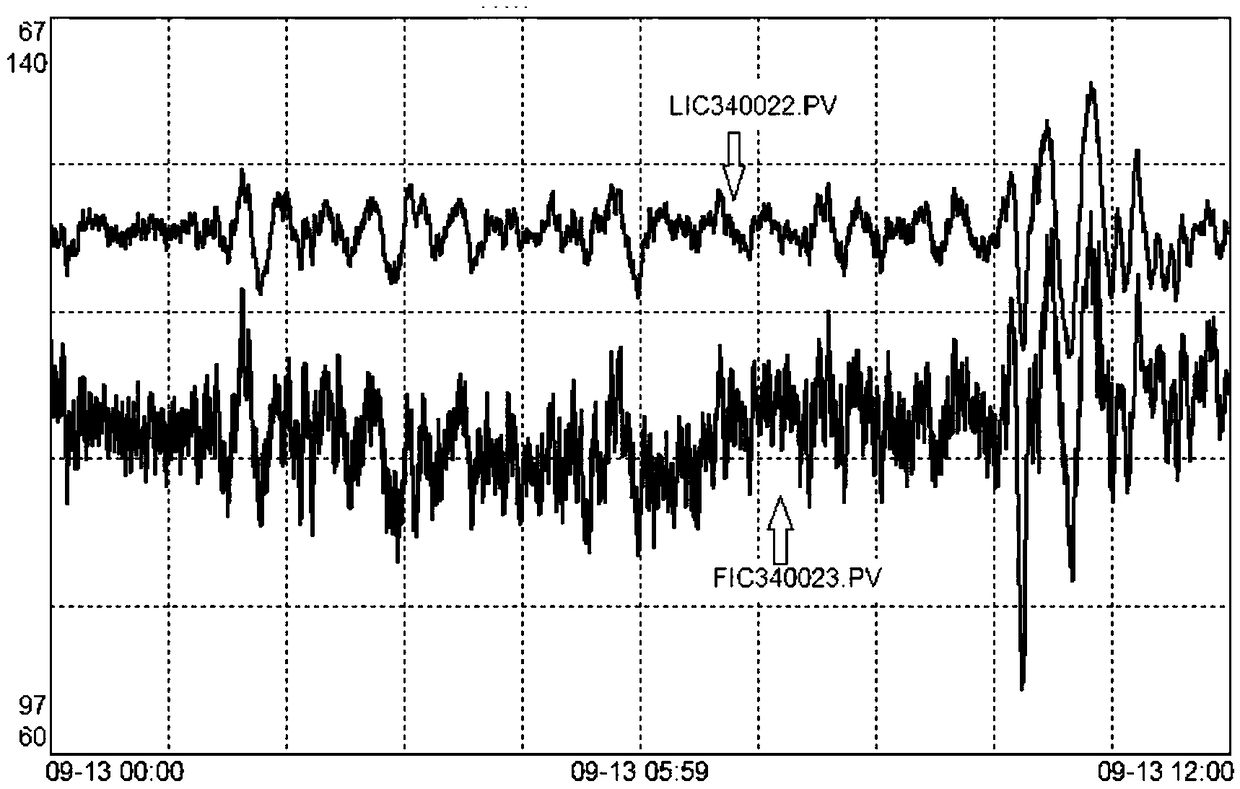

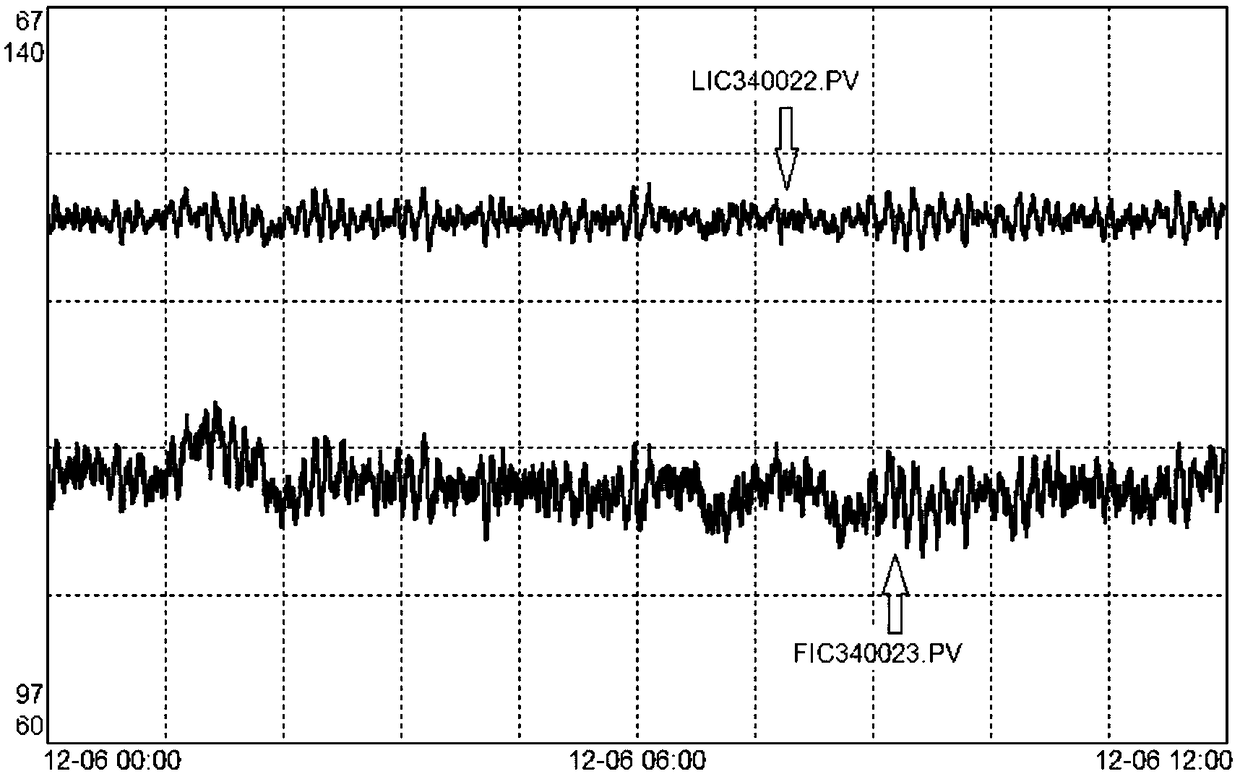

[0028] For a rectification tower object in a refinery, the nonlinear area control method designed by the present invention is implemented for the loop composed of the tower bottom liquid level control loop LIC340022 and the tower bottom outlet flow control loop FIC340023.

[0029] According to the technical parameters provided by the technician, set the adjustment range of the tower top pressure PI340027 to 2.8-3.2MPaG, set the stable area of the liquid level LIC340022 to 40-50, and set the stable threshold of the flow rate to 3.6. According to the empirical parameters provided by the operator, set the adjustment rate of the flow setting value to 3.6 / hour, set the setting value adjustment area of the flow loop to 100-120, and set the valve position adjustment range of the flow loop to 20-90.

[0030] Comparison of control effects before and after impl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com