Stirring cylinder and finished product cabin material separation box fully sealed structure of asphalt stirring station

A kind of asphalt mixing and mixing tank technology, which is applied in the direction of mixer accessories, mixers, dissolving, etc., can solve the problems of environmental pollution, loud noise, and the inability to realize the seamless connection between the mixing tank and the distribution box, and achieve convenient and reliable use. Avoid gas overflow, the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

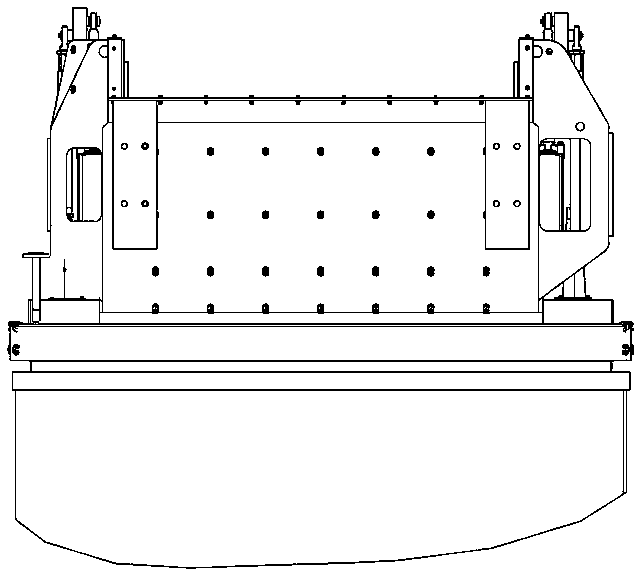

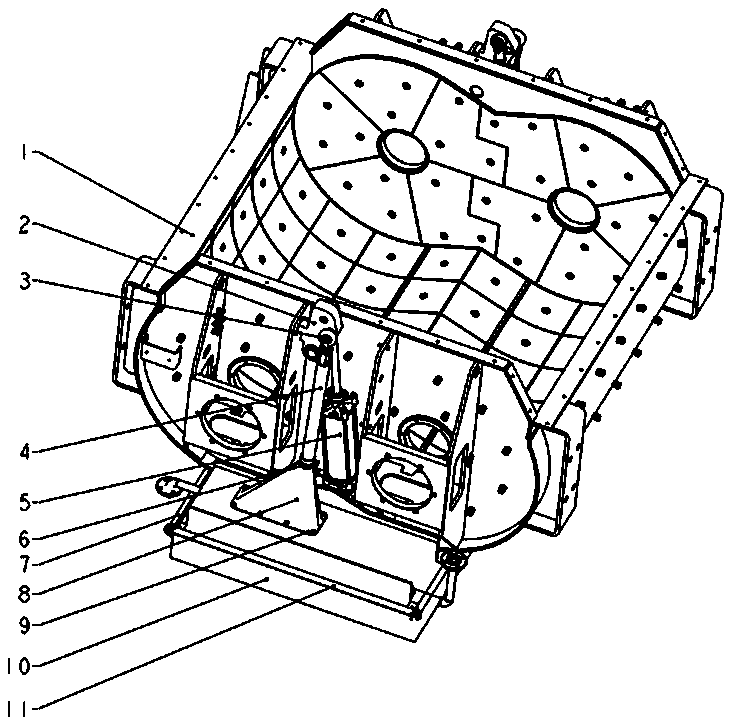

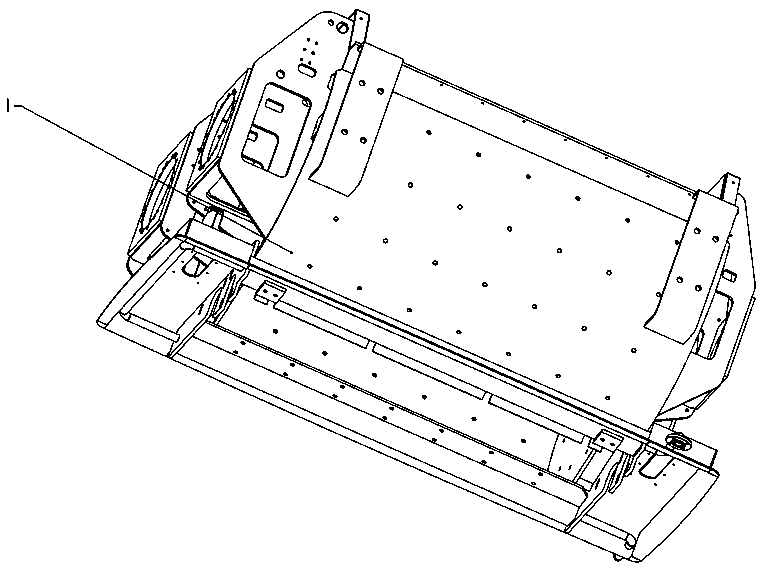

[0014] The patent of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Figure 1-5 As shown, the fully enclosed structure of the mixing tank and the finished product bin distribution box of an asphalt mixing plant according to the present invention includes a metering mixing frame, a mixing tank shell 1, a T-shaped soft connection 8, a pressure plate 9, and a hoop 6 , short clip 7, long clip 11, unloading door driving linkage mechanism, unloading door 14, material distributing device 17, canvas soft connection 10; one end of the T-shaped flexible connection 8 is fixed on the unloading On the drive push rod 4 of the material door 14, the other end of the T-shaped soft connection 8 is fixed on the sealing plate through the pressure plate 9, and the canvas soft connection 10 made of canvas is used to seal the mixing tank and the distribution box of the finished product warehouse, and the canvas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com