A prefabricated box girder steel bar binding mold and its installation method

A technology for tying steel bars and box beams, applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of difficulty in controlling the pass rate of steel bar protective layer, affecting the appearance of finished products, pollution of the bottom plate, etc., to improve the binding speed and binding quality, and easy to operate. , the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are preferred embodiments of the present invention, but the protection scope of the present invention is not limited thereby.

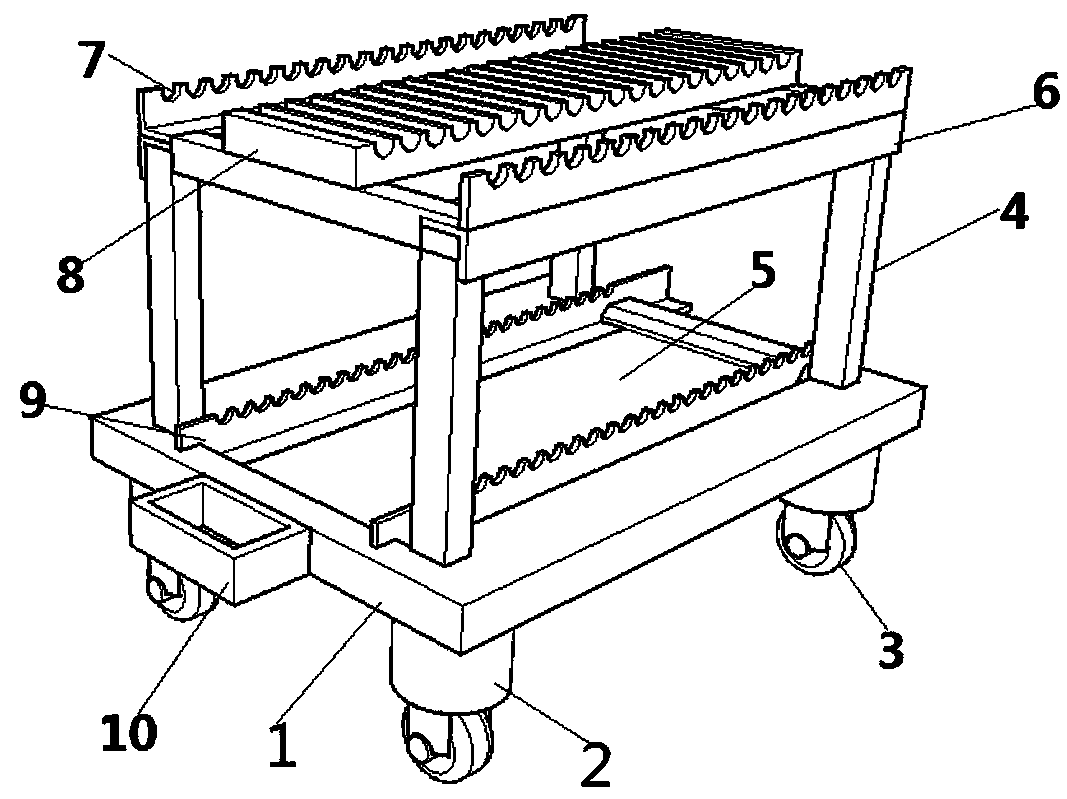

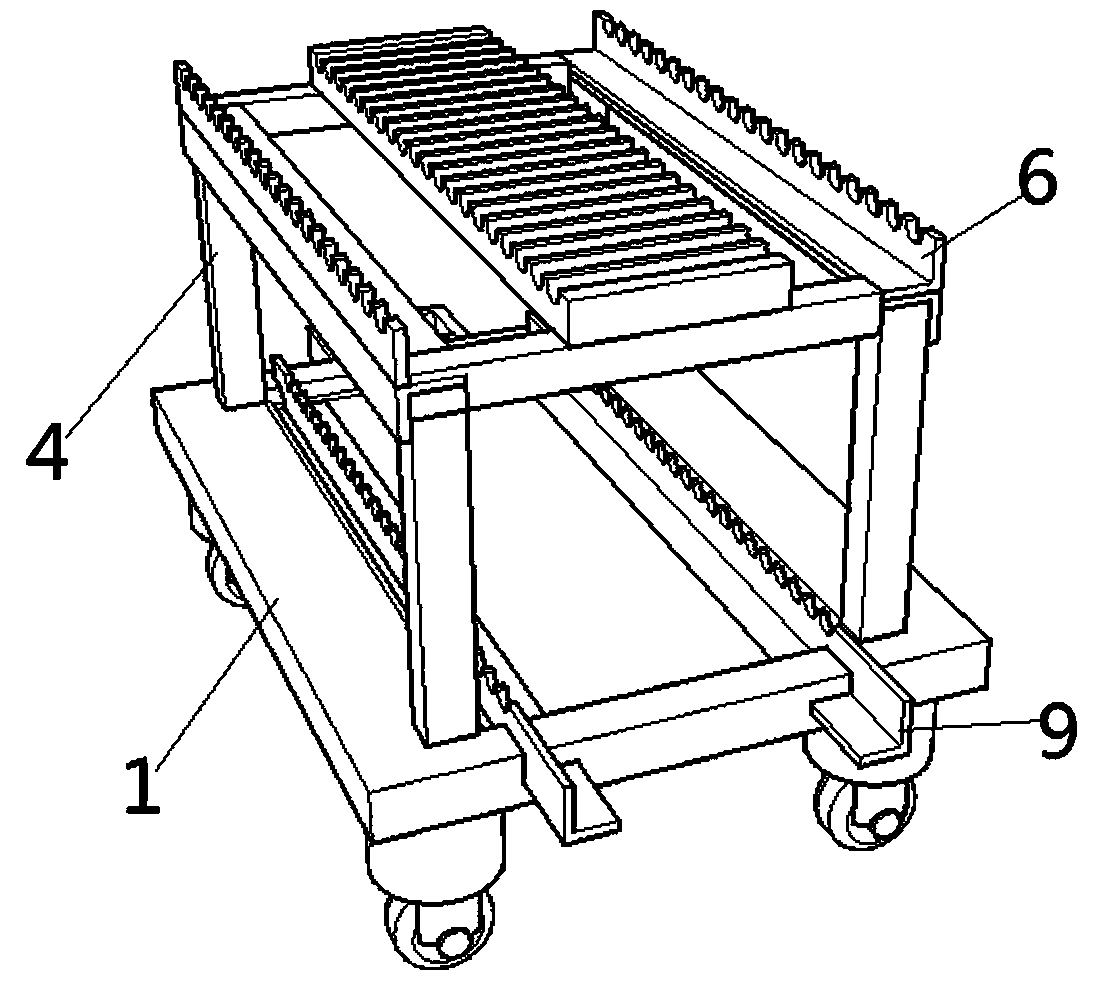

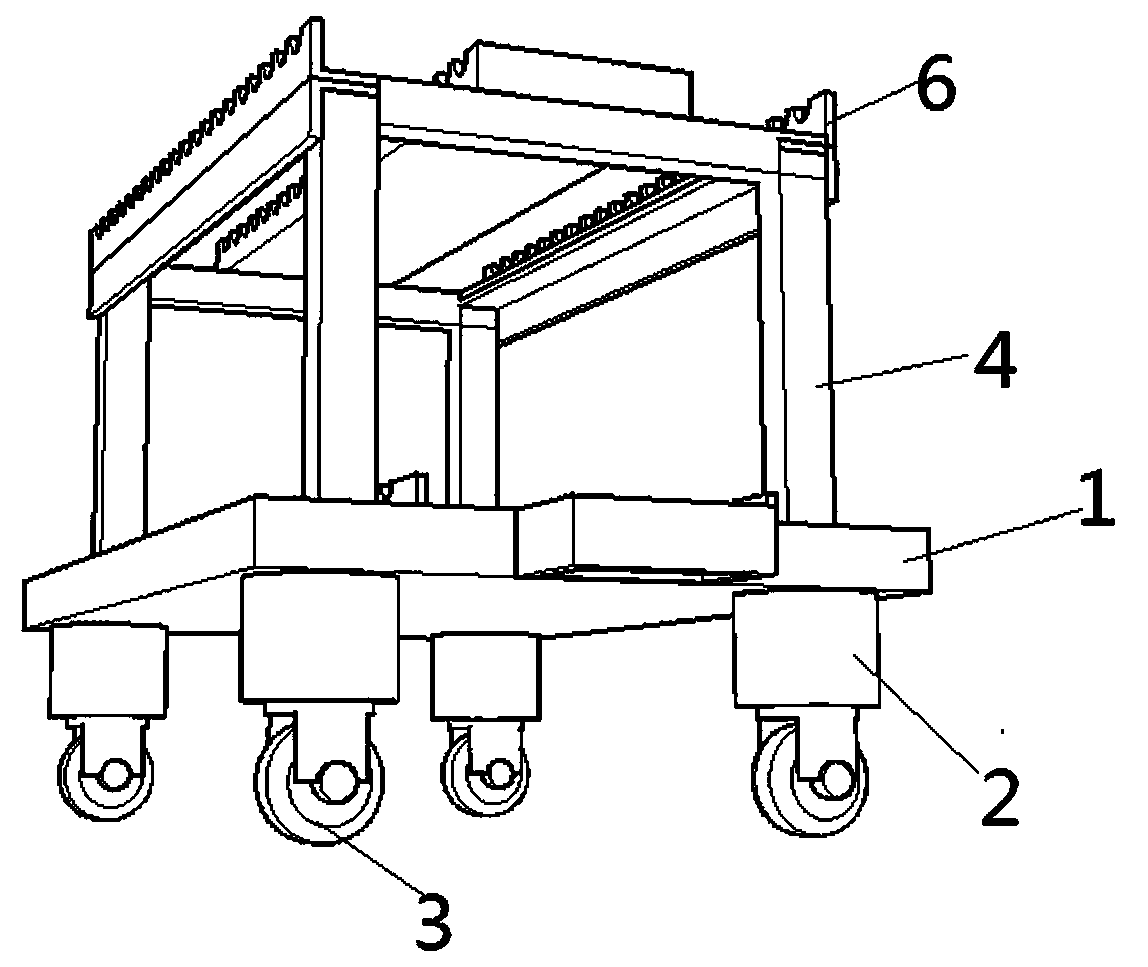

[0023] As shown in the figure, a prefabricated box girder reinforcement tying mold includes a bottom plate 1, a telescopic rod 2, a pulley 3, a frame 4, a groove 5, a T-shaped plate 6, a reinforcement slot 7, an intermediate plate 8, a triangular plate 9, and a traction Block 10; It is characterized in that: the frame 4 and the T-shaped plate 6 form a top plate steel skeleton, wherein the T-shaped plate 6 is composed of two triangular plates welded together, two of which are symmetrical to each other, and are fixedly installed at both ends of the frame 4 T-shaped plate 6, on the T-shaped plate 6 is provided with a plurality of rebar placement grooves 7 arranged in arithmetic rows, and an intermediate plate 8 is fixedly installed on the frame 4, wherein the intermediate plate 8 is located between the two T-shaped plates 6 , The middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com