Support for connecting inner upper surface with inner lower surface of oil tank

A technology for a support body and a fuel tank, which is applied to the support body and the support body connecting the upper and lower surfaces of the fuel tank, can solve the problems of high manufacturing cost of the column, increase of the hollow box body, tearing of the surface of the fuel tank, etc., and achieve low manufacturing cost and low cost. , The effect of preventing fuel tank leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

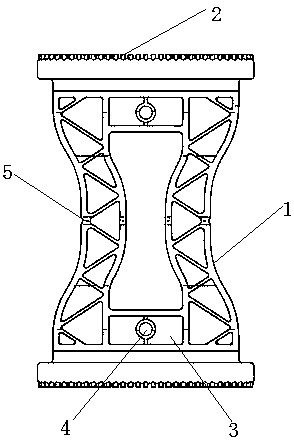

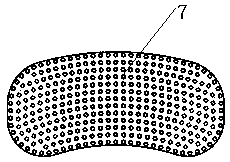

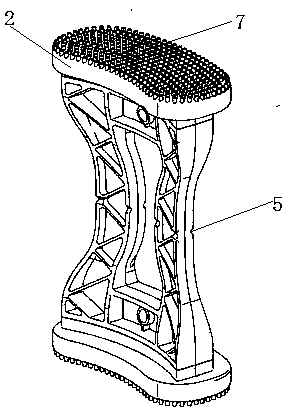

[0022] Embodiment 1: see figure 1 , a support body connecting the upper and lower surfaces inside the fuel tank, the support body includes a connecting column 1, the upper and lower sides of the connecting column are provided with end faces 2, and the end faces 2 are covered with plastic, and the connecting column 1 is A notch 5 is provided, and the number of the connecting column 1 is at least one. In this technical solution, the number of connecting columns is set to two, and the overall shape is set to H shape, and the two connecting columns are connected by connecting rod 3, wherein the connecting rod is provided with a fixing hole 4, and the function of the fixing hole 4 is When lagging the end faces, the entire support is secured. When there are two connecting columns in the middle of the upper and lower ends of the support body, the connecting columns are solid, and the cross-sectional diameter of the end surface of the supporting column is smaller than that of the hol...

Embodiment 2

[0023] Example 2: see figure 1 , image 3 , Figure 4 , as an improvement of the present invention, the connecting column 1 is also set in one of I-shape, M-shape, and W-shape. The notch 5 is set to be V-shaped, U-shaped, semicircular or other irregular figures, and the notch is provided mainly to make the fuel tank not lose its strength, and the connecting column 1 is more likely to break when a collision occurs by utilizing the notch effect, Thereby avoiding the surface of the fuel tank from being torn and preventing the fuel tank from leaking; other structures and advantages are exactly the same as those in Embodiment 1.

Embodiment 3

[0024] Embodiment 3: see figure 1 , image 3 , Figure 4 , as an improvement of the present invention, the notch 5 is set on the left side and / or right side and / or middle of the connecting column. After a large number of experiments, it has been proved that the cracking effect is best when the notch is set in the middle of the connecting column. In addition, according to The height of different connecting columns, the size and shape of the gap all need to be adjusted. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com