An automatic capping machine

A capping machine, automatic technology, applied in the direction of flanged bottle caps, etc., can solve the problems of scrapped caps, unfavorable capping operations, and affecting the normal operation of capping operations, so as to avoid cost losses, efficient and stable capping operations, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

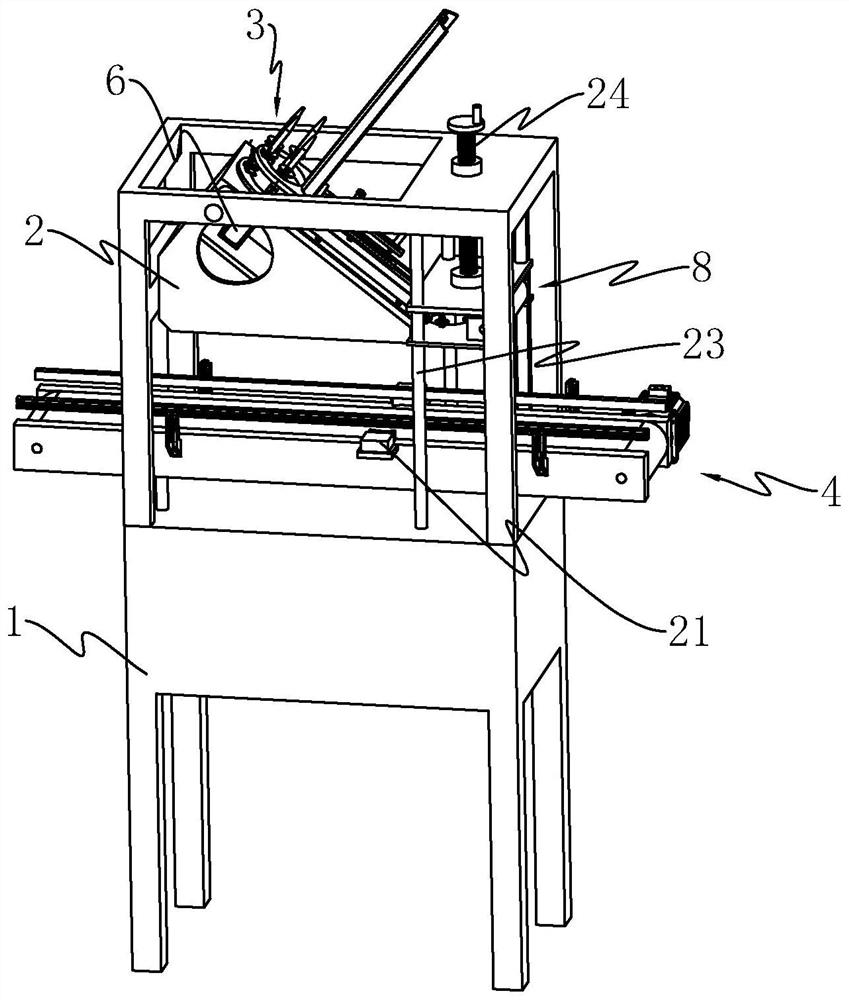

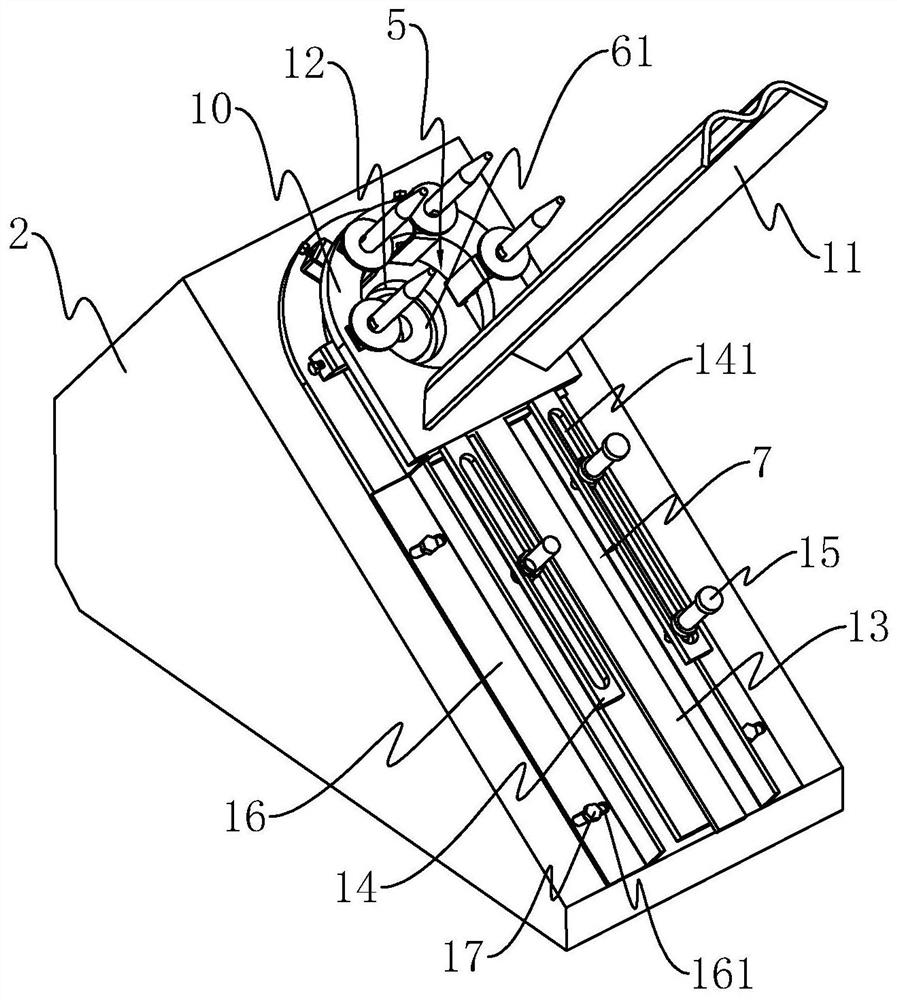

[0029] See attached Figure 1-2 , an automatic capping machine, mainly used for the capping operation of product packaging tanks, it includes a frame 1, a fixed frame 2 is fixed on the frame 1, and a stacking assembly 3 is provided on the fixed frame 2; during work, The can lids are integrally stacked inside the stacking assembly 3 . A conveyor belt 4 is horizontally erected under the fixed frame 2, and the tank body will be horizontally transported under the fixed frame 2 along the conveyor belt 4 during the capping operation.

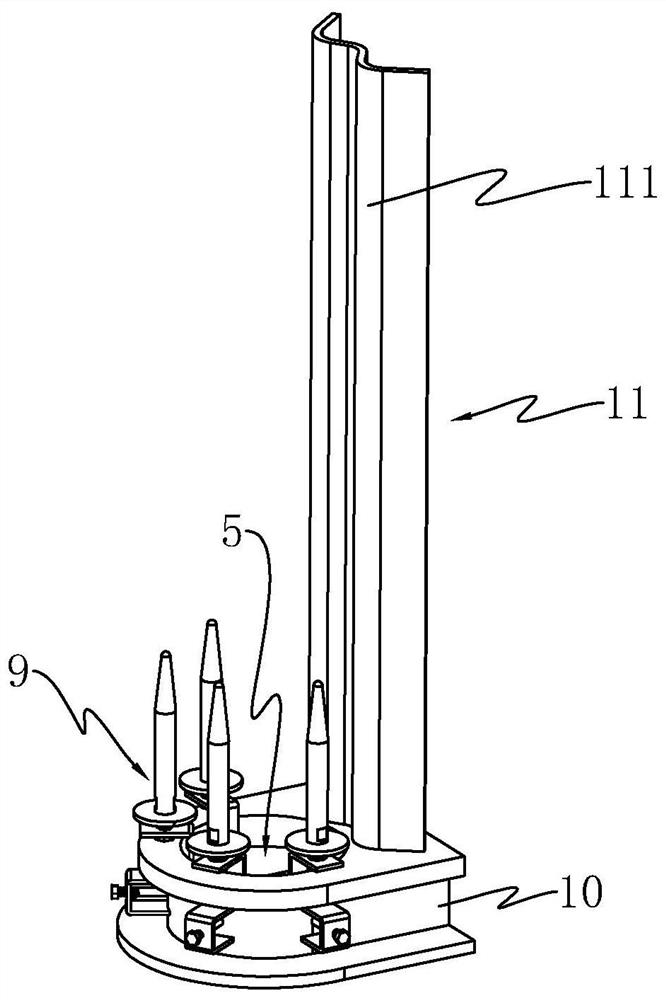

[0030] The bottom of the overlapping assembly 3 is formed with a cover outlet 5 for the can lids to pass through, and a power part is provided below the cover outlet 5 for absorbing each can lid one by one; at the same time, the cover outlet 5 is also connected to the cover outlet channel 7 ; After the tank cover passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com