A plastic structured packing

A technology of structured packing and plastics, applied in the direction of chemical/physical/physical chemical process, chemical instrument and method, chemical/physical process, etc., can solve the problem of limiting the application range of plastic packing, unable to effectively promote liquid phase turbulence, and unfavorable liquid film. Formation and renewal, etc., to achieve the effect of highlighting wetting performance, increasing the effective contact surface area of gas and liquid, and reducing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A new type of plastic wire mesh structured packing of the present invention will be further described below in conjunction with the accompanying drawings.

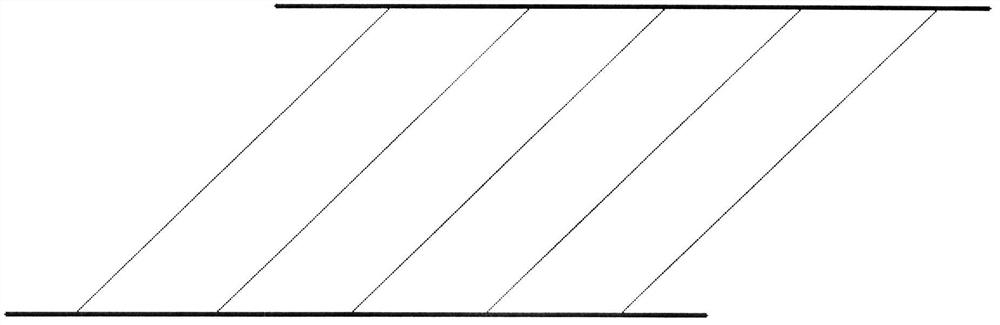

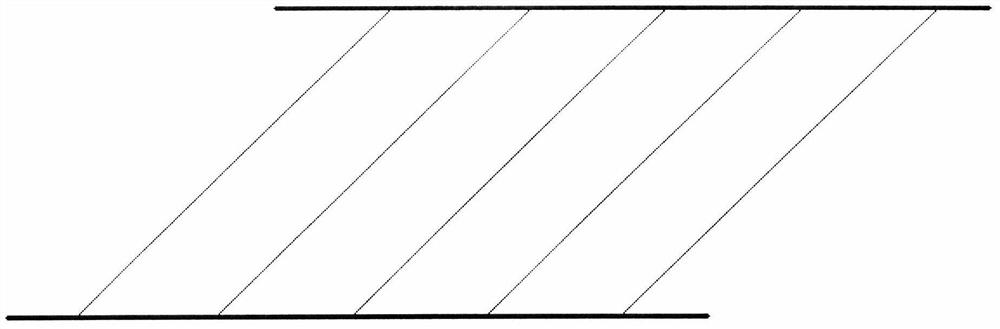

[0030] refer to figure 1 , a kind of corrugated packing for plastic plates involved in the present invention, firstly make plastic ribs on plastic plates of certain thickness, stretch the plastic plates to a certain extent at intervals of a certain distance, and form a certain thickness of embossing between two stretches. It is the plastic ribs. figure 1 Shown is a schematic diagram of the structure of a plastic plate with a rib angle of 45°.

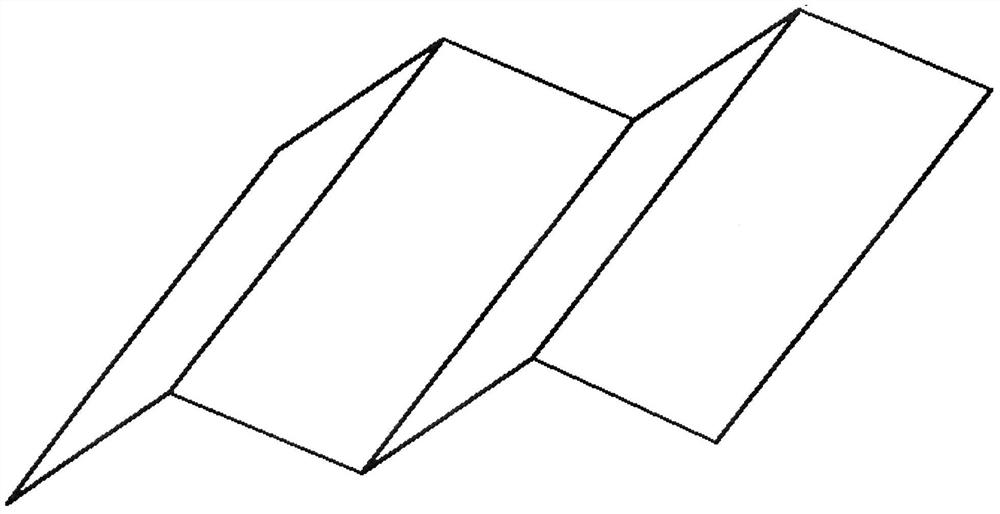

[0031] refer to figure 2 , a kind of corrugated packing of plastic plate that the present invention relates to, is made into figure 1 After the plastic sheet with ribs shown, it is rolled into different corrugated structures according to requirements. figure 2 Shown is a linear plastic sheet corrugated packing sheet with a corrugation inclination angle of 45°.

[0032...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com