Super long muffle tank of horizontal steel strip annealing furnace

An annealing furnace and muffle tank technology, applied in the field of metal heat treatment equipment, can solve the problems of narrow application range, easy deformation, short muffle tank length, etc., and achieve the effect of wide application range, super long length, and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

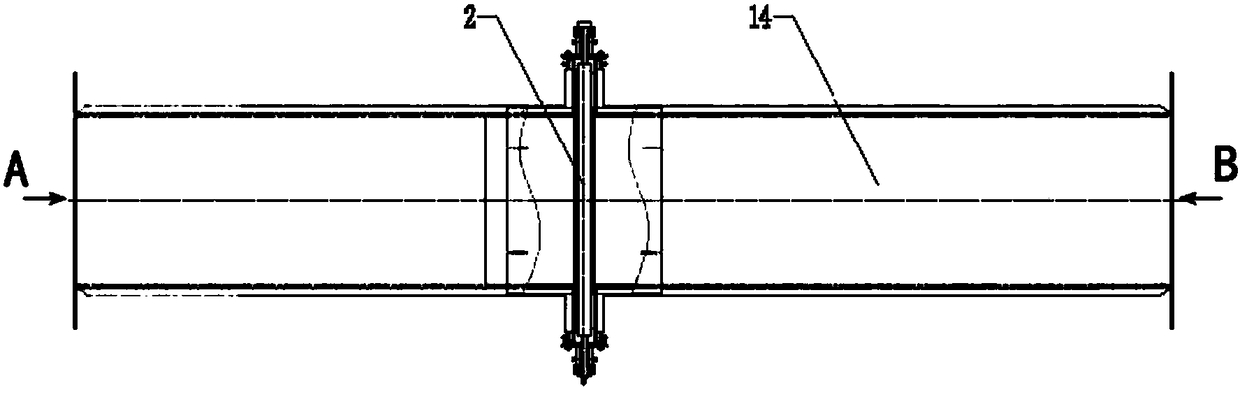

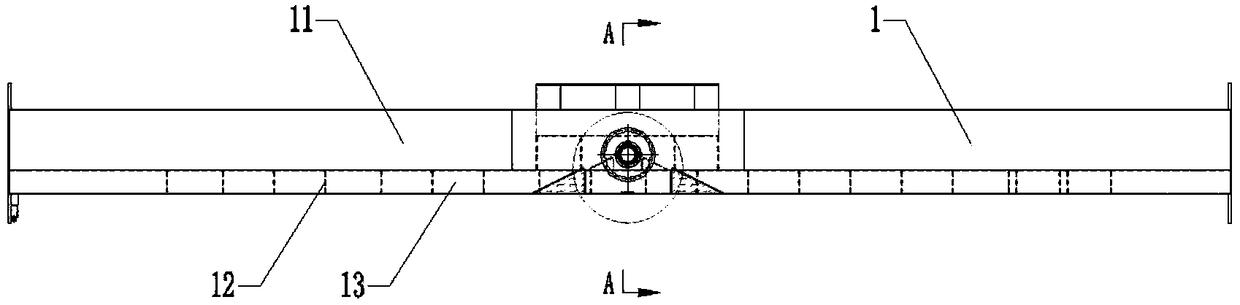

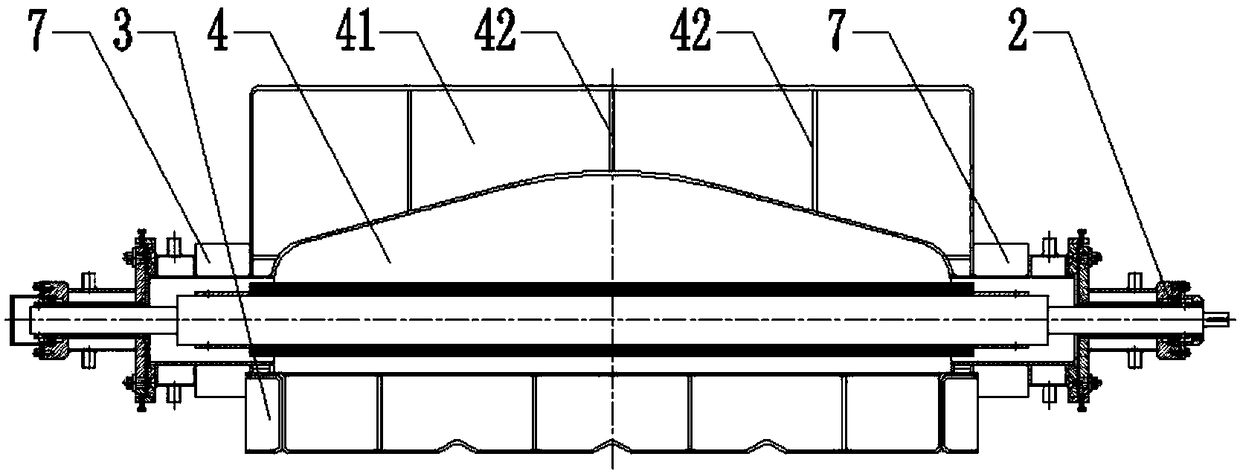

[0027] refer to Figure 1 to Figure 6 , this embodiment includes a tank body 1, the tank body 1 is an ultra-long structure formed by connecting several sections of shells 11, and an idler 2, a lower reinforcing mechanism and an upper reinforcing mechanism are arranged at the joints of adjacent shells 11 ; The two adjacent housings 11 are connected as an integral structure through the lower reinforcement structure 3 and the upper reinforcement structure 4; the lower reinforcement structure includes a reinforcement body 3 arranged on the bottom surface of the casing 11, and several strips The lower reinforcement rib 31, the upper reinforcement mechanism includes an upper reinforcement body 4 arranged on the upper surface of the housing 11, and several upper reinforcement ribs 42 are arranged on the upper reinforcement body 4 to form an integral reinforced connection structure; the supporting rod 2 passes through The reinforced side of the supporting rod is connected with the low...

specific Embodiment

[0042] The characteristics of other specific embodiments of the present invention are: the tank body 1 can adopt an ultra-long structure composed of two, four, five, six or seven or more shells 11 connected according to the process requirements, and its length can be 18 meters, 20 meters, 24 meters, 26 meters, 28 meters, 30 meters. All the other are with specific embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com