Processing method of odor-removing sound-insulation cotton

A processing method and technology of sound insulation cotton, which is applied in textiles and papermaking, fiber treatment, biochemical fiber treatment, etc., can solve problems such as easy to emit odor, sound insulation cotton emits odor, and affect passenger ride experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

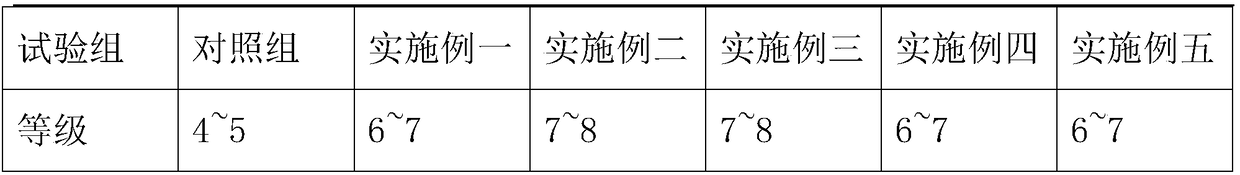

Embodiment 1

[0025] Embodiment 1, a kind of processing method of deodorizing sound insulation cotton:

[0026] In step a, manually select the leftovers purchased from the garment factory, pick out the mixed cotton, silk and other fabrics, and collect the remaining chemical fiber fabrics together.

[0027] Step b, soak the picked out chemical fiber cloth in the mixed solution of desizing enzyme and penetrating agent according to the bath ratio of 1:10, the concentration of desizing enzyme is 3g / L, and the concentration of penetrating agent is 5g / L. The temperature of the solution is kept at 50-60° C., soaked and boiled for 20 minutes to desizing.

[0028] In step c, pass the soaked cloth through clean water, rinse it, and then dry it.

[0029] In step d, put the dried cloth into the deodorant solution with a concentration of 5g / L according to the bath ratio of 1:10, and then soak and boil to remove the odor. The soaking temperature is 50-60° C., and the soaking time is 20 minutes.

[003...

Embodiment 2

[0033] Embodiment 2, a kind of processing method of deodorizing sound insulation cotton:

[0034] In step a, manually select the leftovers purchased from the garment factory, pick out the mixed cotton, silk and other fabrics, and collect the remaining chemical fiber fabrics together.

[0035] In step b, soak the selected cloth made of chemical fiber into the mixed solution of desizing enzyme and penetrating agent at a bath ratio of 1:10, the concentration of desizing enzyme is 4g / L, and the concentration of penetrating agent is 5g / L. The temperature of the solution is kept at 60-70° C., soaked and boiled for 20 minutes to desizing.

[0036] In step c, pass the soaked cloth through clean water, rinse it, and then dry it.

[0037] In step d, put the dried cloth into the deodorant solution with a concentration of 6g / L according to the bath ratio of 1:10, and soak it to remove the odor. The soaking temperature is 60-70°C, and the soaking time is 20 minutes.

[0038] Step e, dry...

Embodiment 3

[0041] Embodiment three, a kind of processing method of deodorizing sound insulation cotton:

[0042] In step a, manually select the leftovers purchased from the garment factory, pick out the mixed cotton, silk and other fabrics, and collect the remaining chemical fiber fabrics together.

[0043] In step b, soak the selected cloth made of chemical fiber into the mixed solution of desizing enzyme and penetrating agent according to the bath ratio of 1:12, the concentration of desizing enzyme is 5g / L, and the concentration of penetrating agent is 5g / L. When soaking, first put the cloth into the mixed solution of desizing enzyme and penetrating agent, then heat the solution to 100°C, keep it boiling for 5-10 minutes, and then soak the cloth in the mixed solution with the mixed solution Cool naturally, soak and boil the cloth for a total of 20 minutes, and desizing it.

[0044] In step c, pass the soaked cloth through clean water, rinse it, and then dry it.

[0045] Step d, put t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com