Self-running heating furnace capable of performing self-generating electricity

A self-operating and heating furnace technology, applied in the field of heating furnaces, can solve problems such as the failure of normal combustion and heating of the furnace, the limited power supply of the furnace, and the inability to use the heating furnace, etc., to achieve compact structure, energy saving, and easy adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

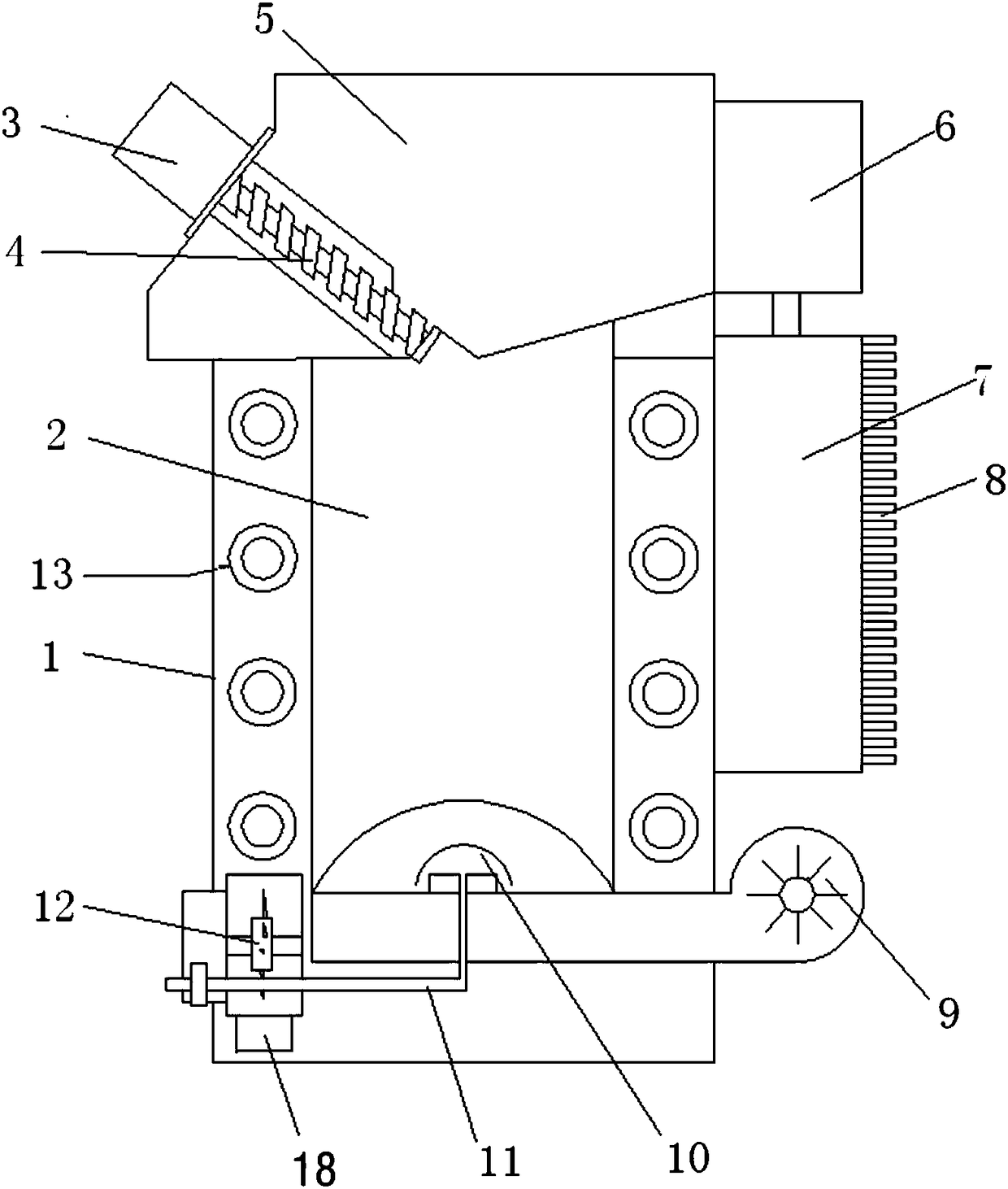

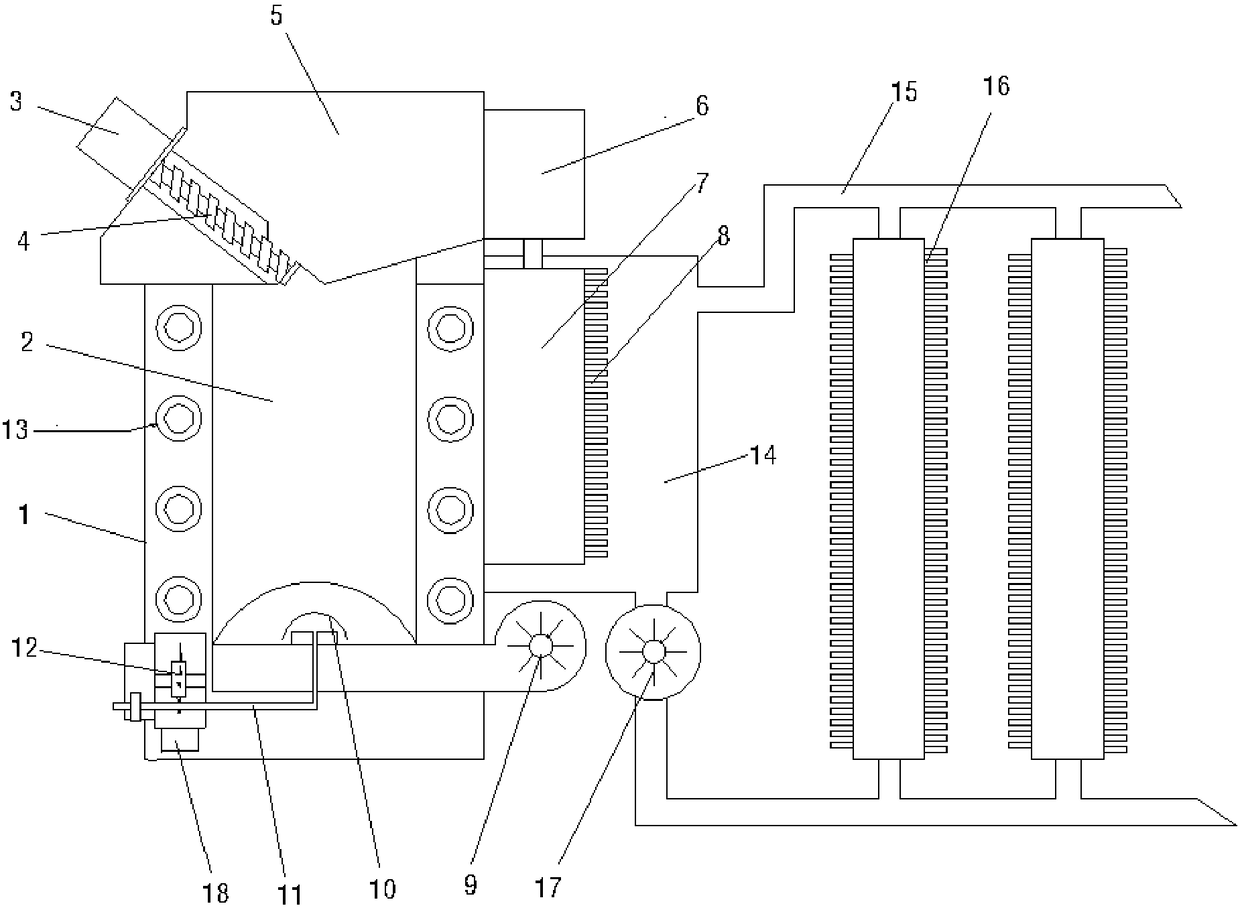

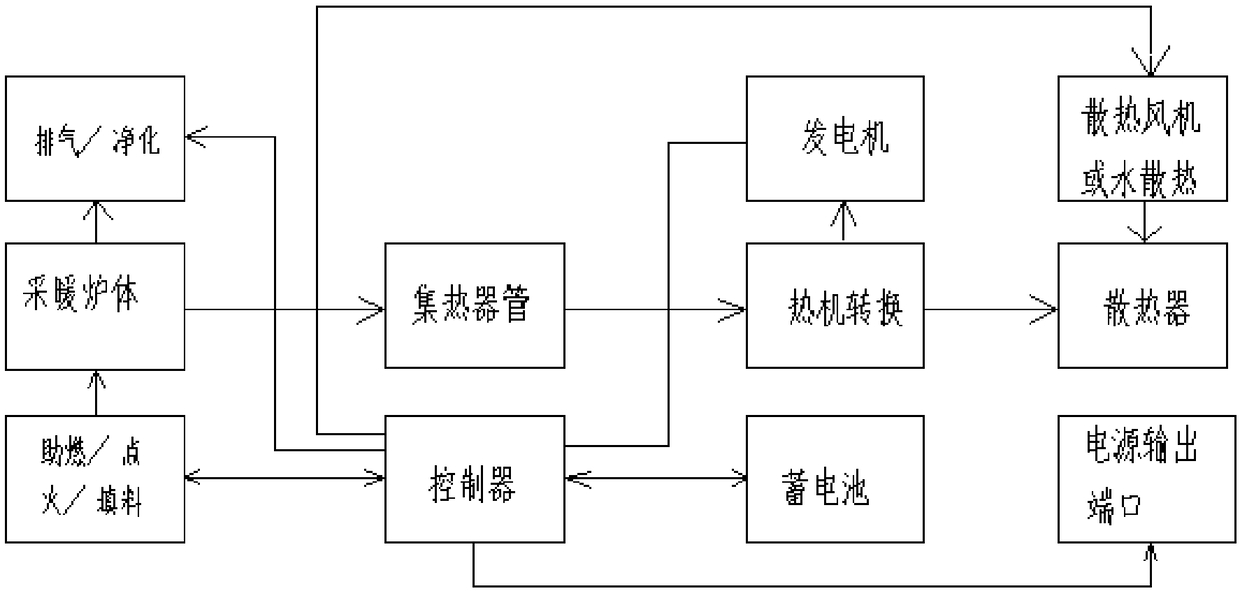

[0031] Refer to attached Figures 1 to 2 As shown, the self-operated heating furnace capable of generating electricity in the present invention includes a furnace body 1, a heat-engine conversion device, a generator 6 and a storage battery.

[0032] In this embodiment, the inside of the body of furnace 1 is provided with a furnace 2 for burning fuel. The self-operating heating furnace can use various energy materials as fuel, such as fuel oil, gas, biomass and other thermal energy that can provide combustion heat. energy.

[0033] The top of the body of furnace 1 is provided with an automatic feeding mechanism. The automatic feeding mechanism includes a storage bin 5 , a feeding screw 4 and a feeding motor 3 . The bottom of the storage bin 5 is provided with a discharge port, and the feeding screw 4 is located at the discharge port, and is driven by the feed motor 3 to realize feeding into the furnace 2 . The automatic feeding mechanism is used to provide biomass fuels such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com