Repairing method for heat exchange tube of graphite heat exchanger

A technology of graphite heat exchanger and heat exchange tube, which can be used in the direction of measuring the acceleration and deceleration rate of fluid, using liquid/vacuum degree for liquid tightness measurement, etc., which can solve the problems of leakage detection and replacement of heat exchange tubes, etc. , to achieve the effect of fast sealing, ensuring sealing tightness, and ensuring tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0057] Embodiment 1: The present invention will be described in detail below in conjunction with the accompanying drawings:

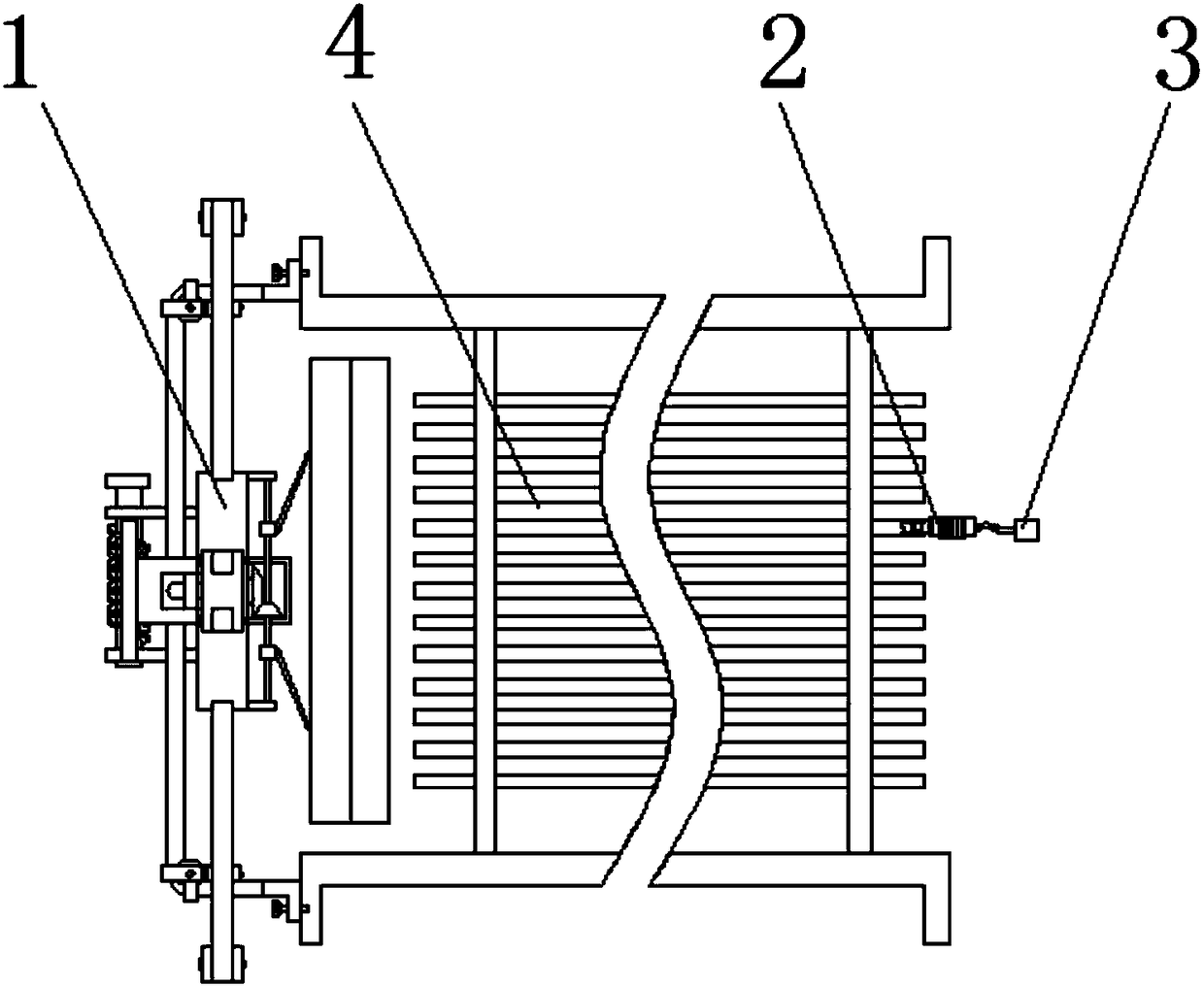

[0058] combine figure 1 As shown, a leakage point detection device of a graphite heat exchanger disclosed in this embodiment includes a plugging device 1, a detection head 2, an industrial computer 3 and a plug, and the plugging device 1 is installed on the One side of the heat exchanger 4, the detection head 2 is inserted into the heat exchange tube on the other side of the heat exchanger 4, the detection head 2 is connected with the industrial computer 3; one end of the heat exchanger 4 is sealed by the sealing device 1 , the heat exchange tubes in the heat exchanger are sequentially sealed by the probe 2, and the vacuum pressure is maintained by the industrial computer 3, and then the damaged heat exchange tubes are detected;

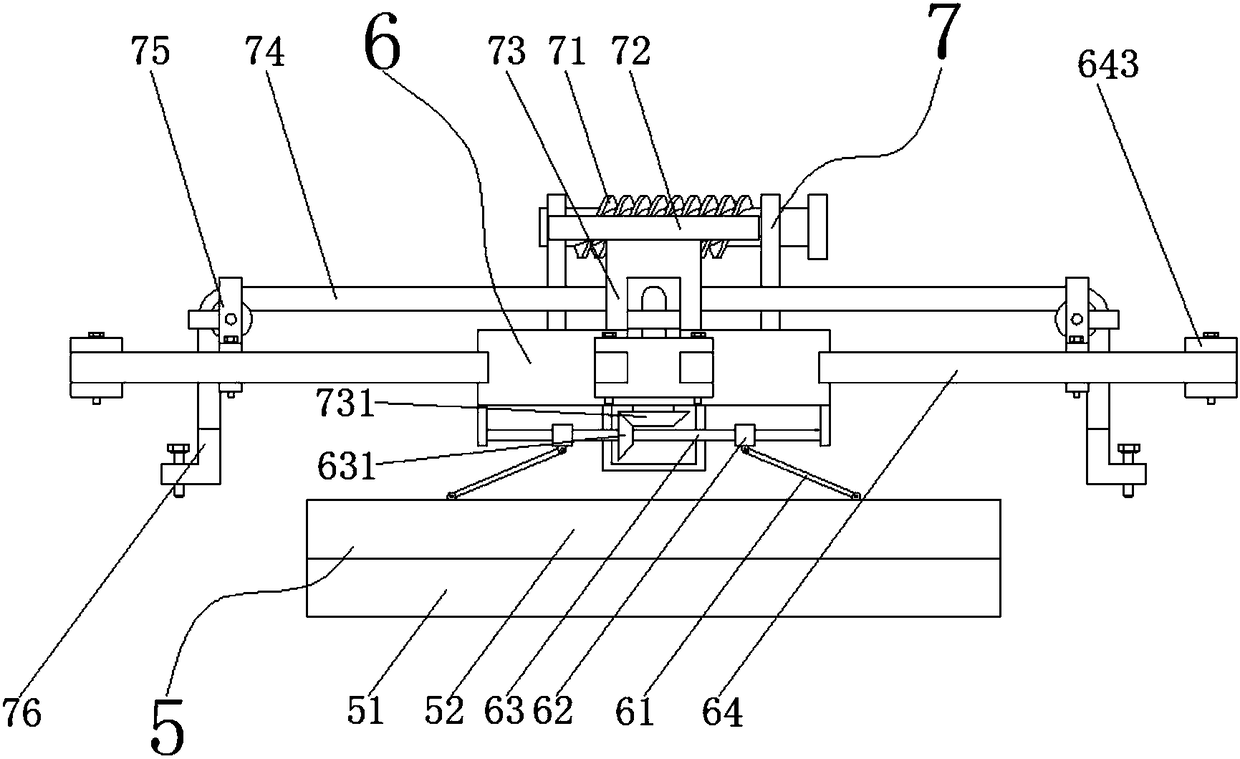

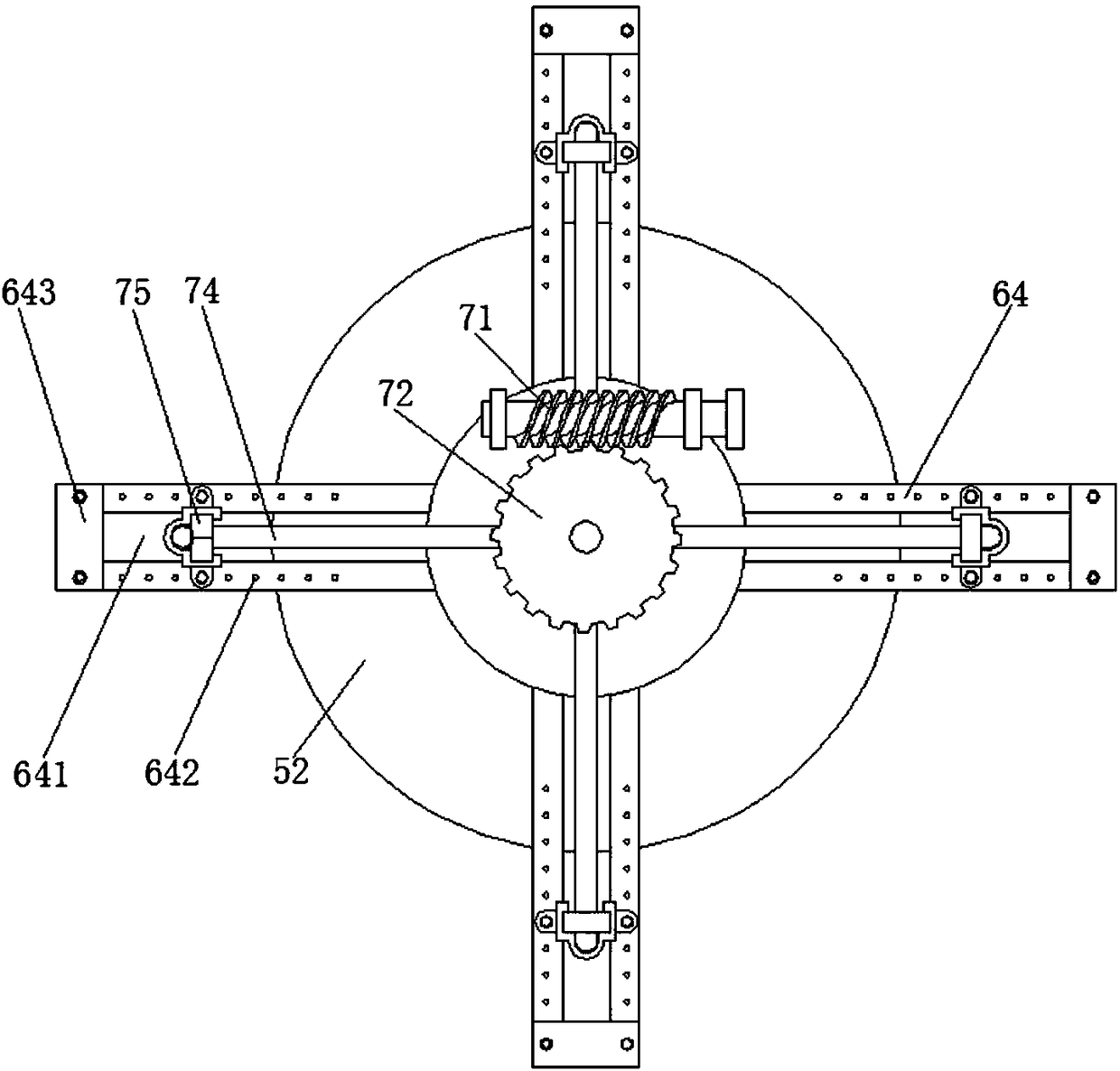

[0059] combine figure 2 and image 3 As shown, the blocking device 1 includes a blocking disk 5, a fixed disk 6 and a lo...

specific Embodiment approach 2

[0068] Specific implementation mode two, this implementation mode is based on the specific implementation mode one, specifically:

[0069] Specifically, the outer end of the fixed arm 64 is also provided with a limiting terminal 643, and the two ends of the limiting terminal 643 are provided with a card slot, and the card slot is connected with the fixed arm 64 through a bolt, and the axial slide groove 641 Sealing, moving pulley 75 comes off.

[0070] Specifically, the detection head 2 is provided with an anti-slip sleeve 25 to prevent the detection head 2 from slipping.

[0071] Specifically, the end of the lead screw 71 is provided with a handwheel, which is convenient for locking the device.

specific Embodiment approach 3

[0072] Specific embodiment three, a negative pressure graphite heat exchanger detection method disclosed in this embodiment, the method is implemented on a leakage point detection device of a graphite heat exchanger described in specific embodiment one or two, including The following steps:

[0073] Step a: Open the flanges at both ends of the graphite heat exchanger, and rinse and dry the heat exchange tubes;

[0074]Step b: On one side of the graphite heat exchanger, adjust the plugging device, select a plugging disc of an appropriate size according to the model of the graphite heat exchanger, adjust the position of the moving pulley on the fixed arm and fix it with bolts. Fix the locking seat on the flange at the end of the graphite heat exchanger, rotate the hand wheel at the end of the screw, the screw rotates to drive the gear to rotate, the gear drives the rotating shaft to rotate, the rotating shaft pulls the locking rope tightly, and the locking rope Wrapped on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com