Safety helmet quality detection system and detection method based on time-domain transient analysis

A quality inspection method and transient analysis technology, applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problems of inaccurate quality inspection of helmets, inability to detect sudden changes in force values or critical damage, etc. , to achieve good practical value and promotion significance, accurate detection and judgment, and the effect of improving the accuracy of judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1. This embodiment proposes a safety helmet quality detection method based on time-domain transient analysis, which specifically includes the following steps:

[0045] A. Collect and store the force value change data of the helmet during the whole test of the helmet puncture test;

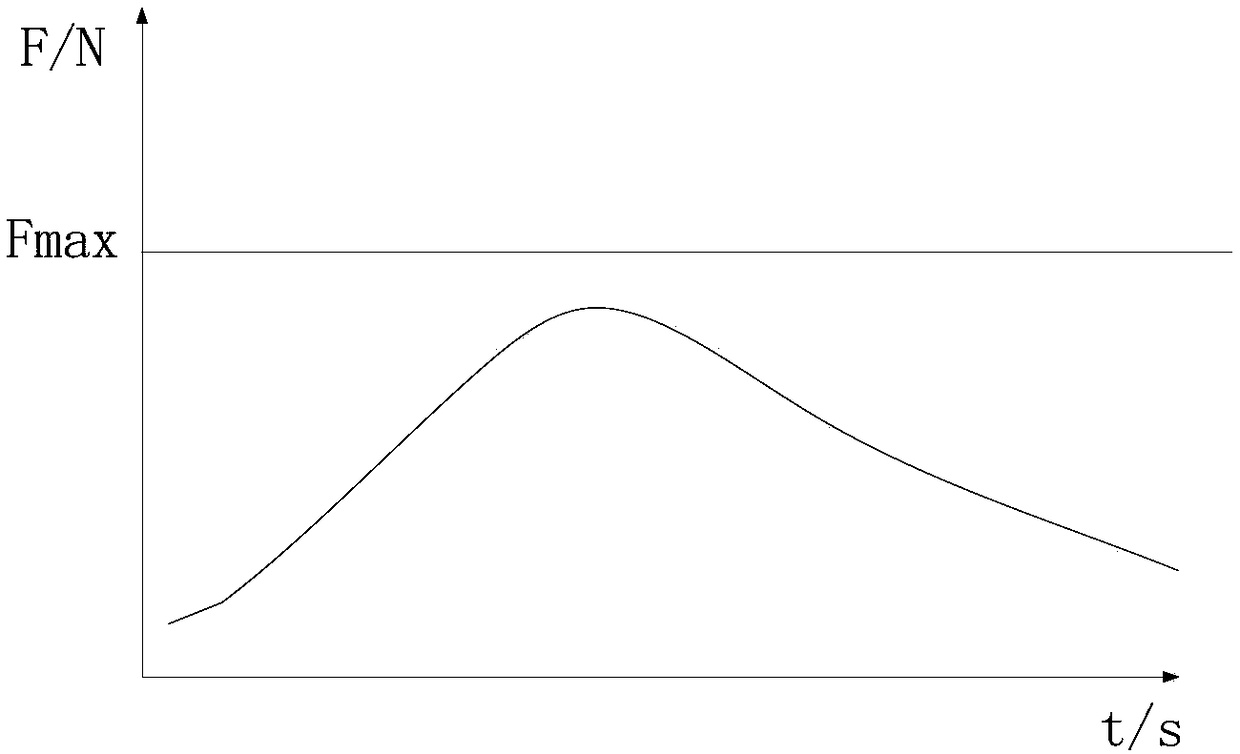

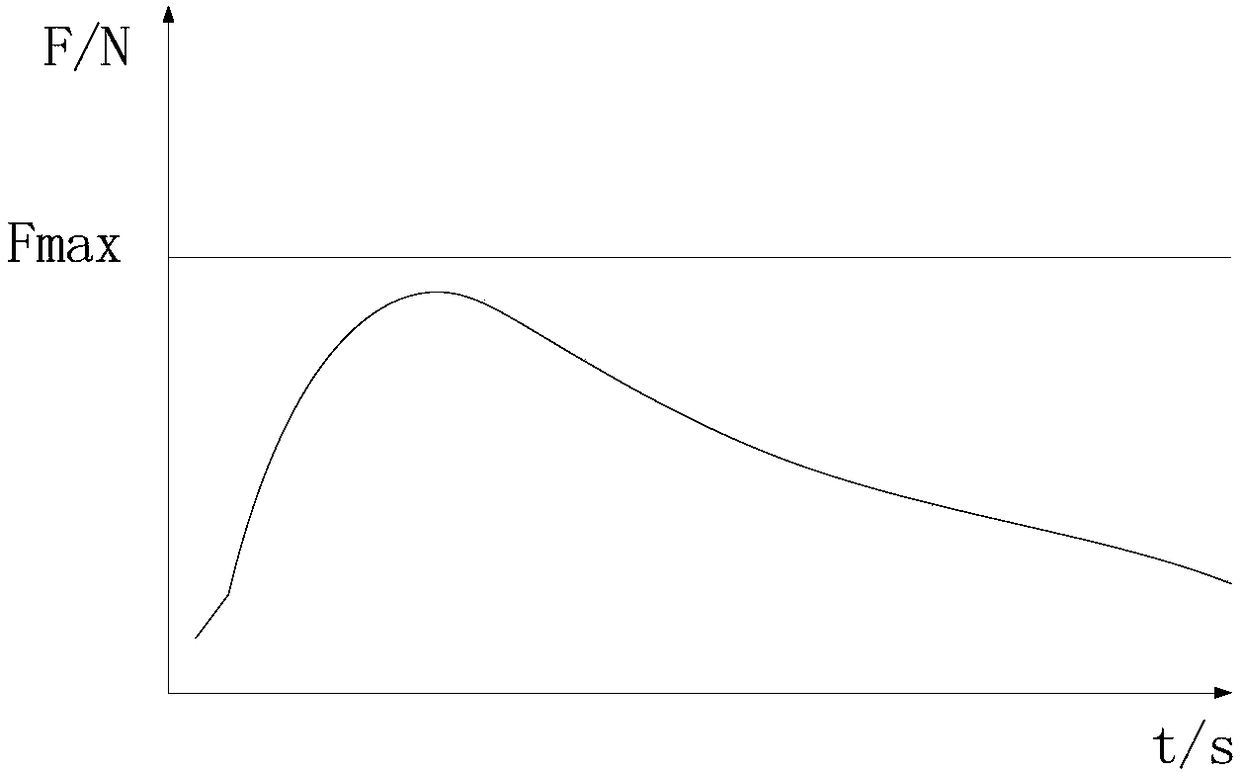

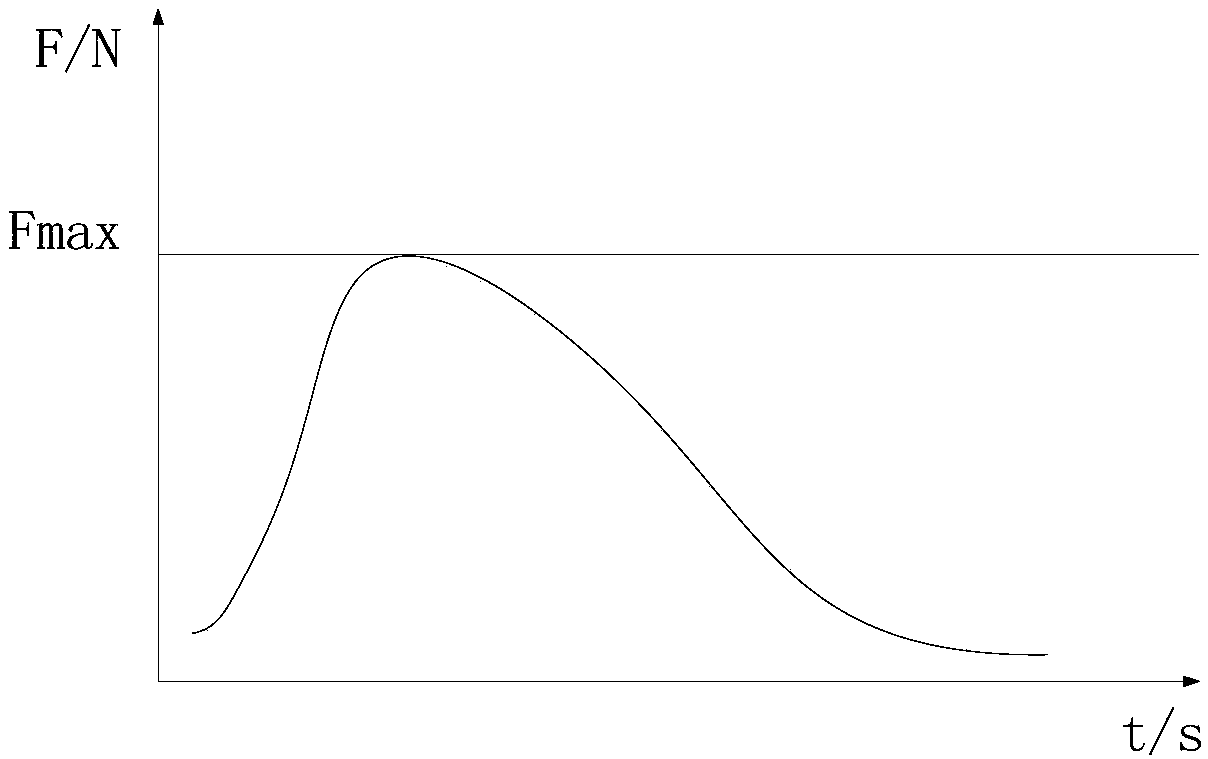

[0046] B. Based on the change data of the force value above, analyze and obtain the maximum force value of the helmet during the entire test process, so as to determine the rising period and the falling period of the force value of the helmet;

[0047] C. If the maximum value of the force in step B exceeds the safety standard value, it can be directly determined that the quality of the safety helmet is unqualified; if not, then perform step D;

[0048] D. Carry out time-domain analysis on the data of the rising section of the force value and the data of the falling section of the force value respectively, and judge whether there is a sudden change in the force value:

[0049] D1....

Embodiment 2

[0063] Embodiment 2, based on the detection method described in Embodiment 1, this embodiment proposes a safety helmet quality detection system based on time-domain transient analysis, refer to Figure 5 Its functional block diagram includes the main control module, pressure signal acquisition and conversion module, A / D converter, memory and LCD display, and the memory and LCD display are connected to the main control module; the pressure signal acquisition and conversion module passes through the A / D The D converter is connected to the main control module, and the pressure signal acquisition and conversion module is used to quickly and linearly convert the pressure value of the helmet during the helmet puncture test into a voltage signal (for example, the input force value 0-2000N corresponds to the output voltage 0-10V), the A / D converter quickly converts the voltage signal into a digital signal that the main control module can receive and process (for example, 40ms acquisiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com