An experimental device and method for recording detonation cell structure

An experimental device and cell technology, applied in the field of detonation testing, can solve the problems of poor heat resistance, damaged film, impact, etc., and achieve the effect of good heat resistance, good strength and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

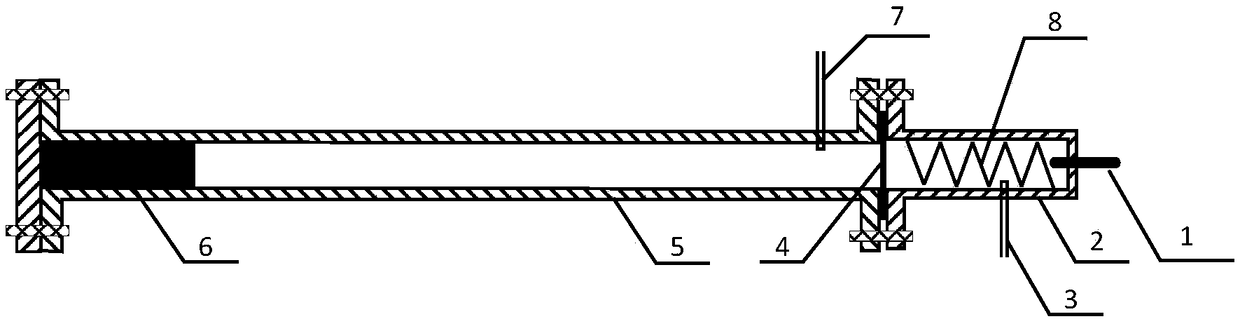

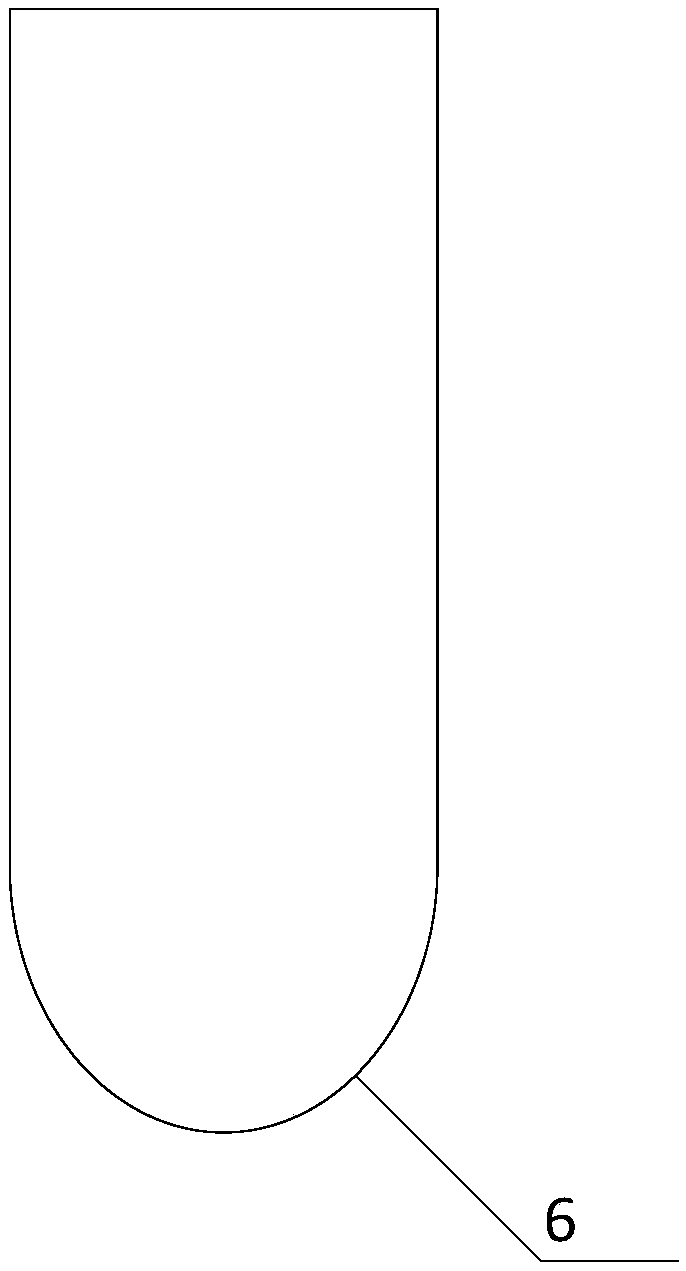

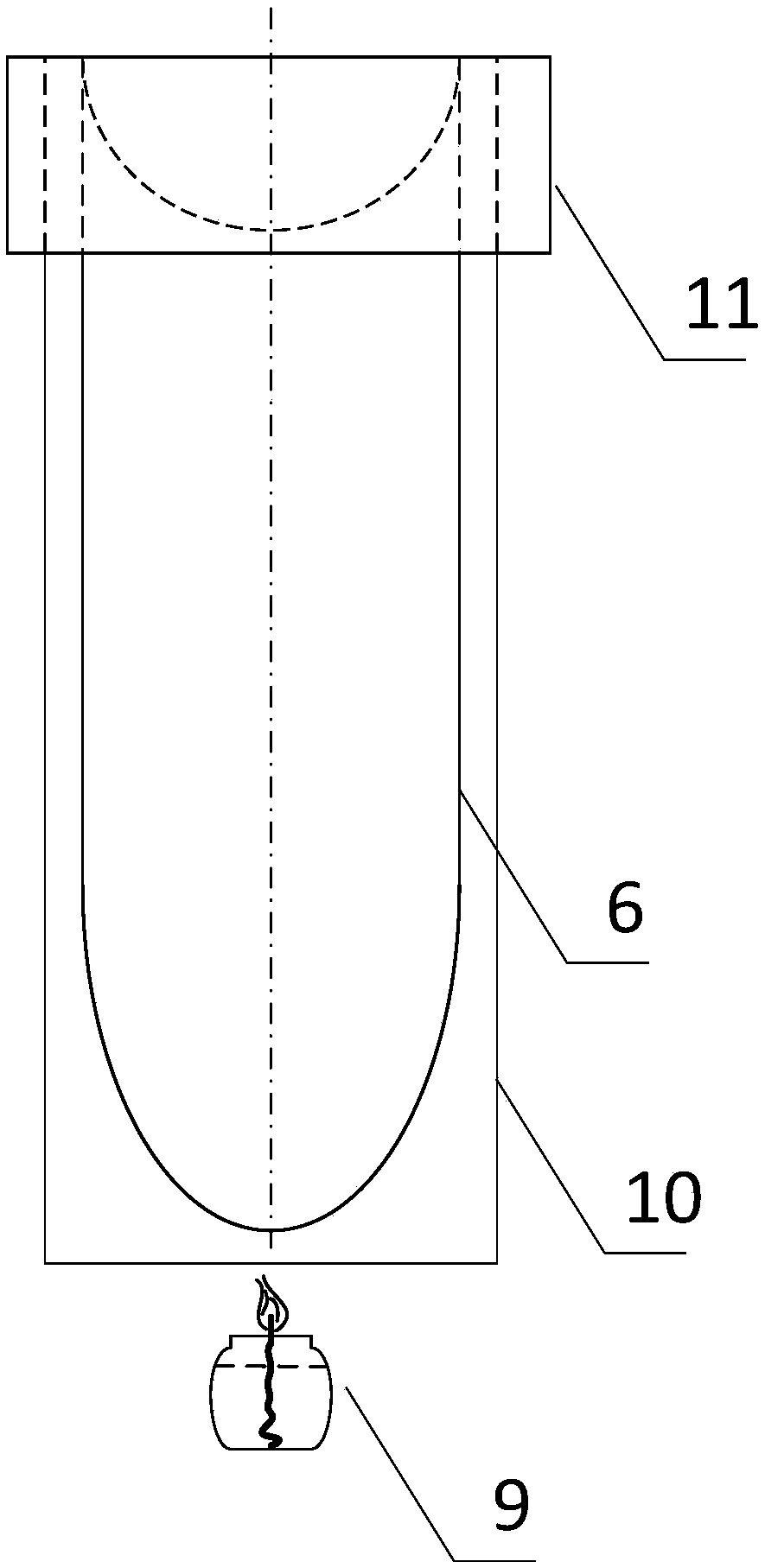

[0020] Such as figure 1 As shown, the present invention is an experimental device for recording detonation cell structure. The main section of the experiment is a detonation tube 5. The front end of the detonation tube 5 is connected to the driving section 2. The flame disturbs the spiral structure 8 so as to accelerate the flame; since the gas filled in the detonation tube 5 and the driving section 2 are different, the diaphragm 4 is used for isolation; The intake pipe 7 and the intake pipe 3 of the detonation section of acetylene; the smoked aluminum plate 6 formed by rolling is arranged in the end of the detonation tube 5, the smoked aluminum plate 6 is closely attached to the tube wall of the detonation tube 5, and the smoked aluminum plate 6 The width is 10-30mm smaller than the circumference of the detonation tube 5, and the winding gap is placed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap