A silicon wafer cleaning and drying integrated device and cleaning method thereof

A technology for cleaning and drying silicon wafers, which is applied in cleaning methods and utensils, chemical instruments and methods, and cleaning methods using liquids, etc., and can solve the problems of rapid drying of difficult silicon wafer surfaces, difficulty in cleaning, and low cleaning strength. Achieve the effect of improving cleaning quality and cleaning efficiency, increasing fluidity and turbulence, and avoiding strong impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

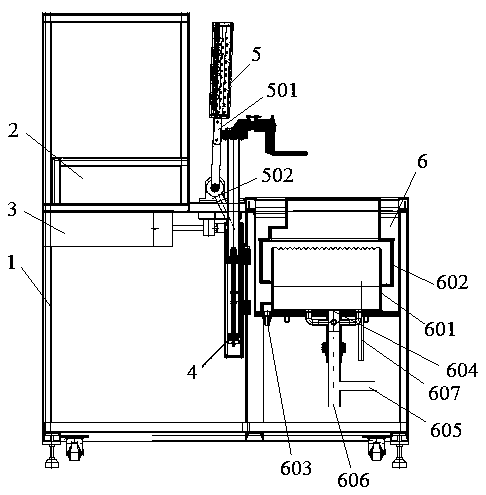

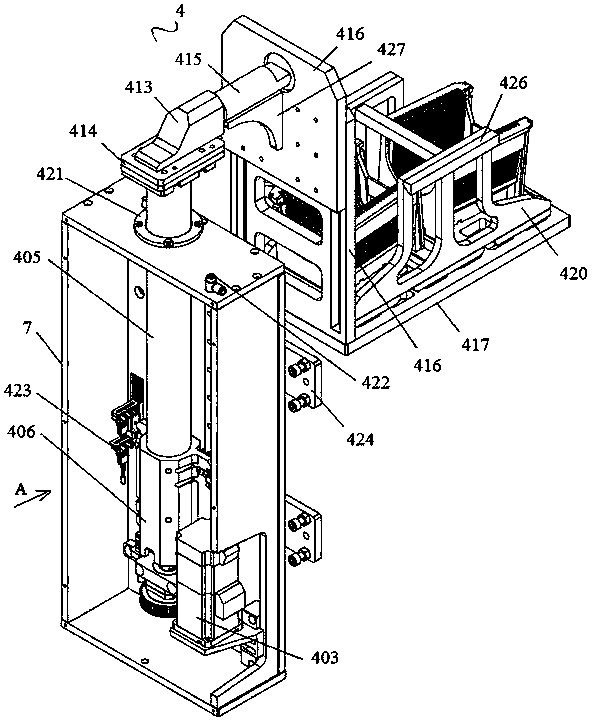

[0031] like Figure 1-6 As shown, the silicon wafer cleaning and drying integrated device of this embodiment includes a movable frame 1, and a control cabinet 2, a cylinder 3, a lifting device 4, an automatic cover plate 5 and a cleaning tank are arranged in the movable frame 1 6. The lifting device 4 is arranged in the box body 7, and one side of the box body 7 is provided with a bracket for placing a silicon chip carrying flower basket,

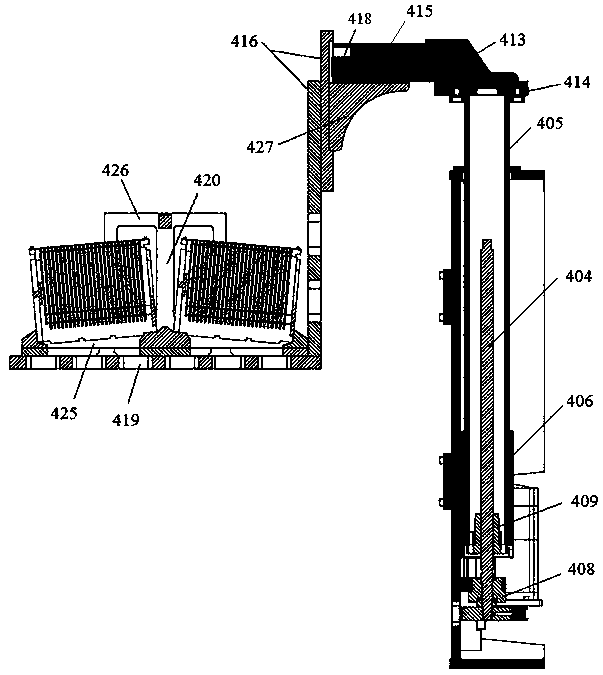

[0032] The lifting device 4 includes a driving motor 403, a screw mandrel 404, a connecting rod 405, and a connecting sleeve 406. The driving motor 403 is arranged on the bottom surface of the casing 7, and the driving motor 403 drives the screw mandrel 404 to rotate through a gear. , a limit slot 407 is provided at the bottom of the screw rod 404, a limit block 408 matching the limit slot 407 is provided in the limit slot 407, a nut 409 is provided on the screw rod 404, The internal thread of the nut 409 is threadedly connected with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com