Verification-repair tool and method of wafer adapter

A repair method and adapter technology, which are applied in the manufacturing of electric solid state devices, semiconductor devices, semiconductor/solid state devices, etc., can solve the problems of failure in the grasping process, difficult to repair equipment use standards, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

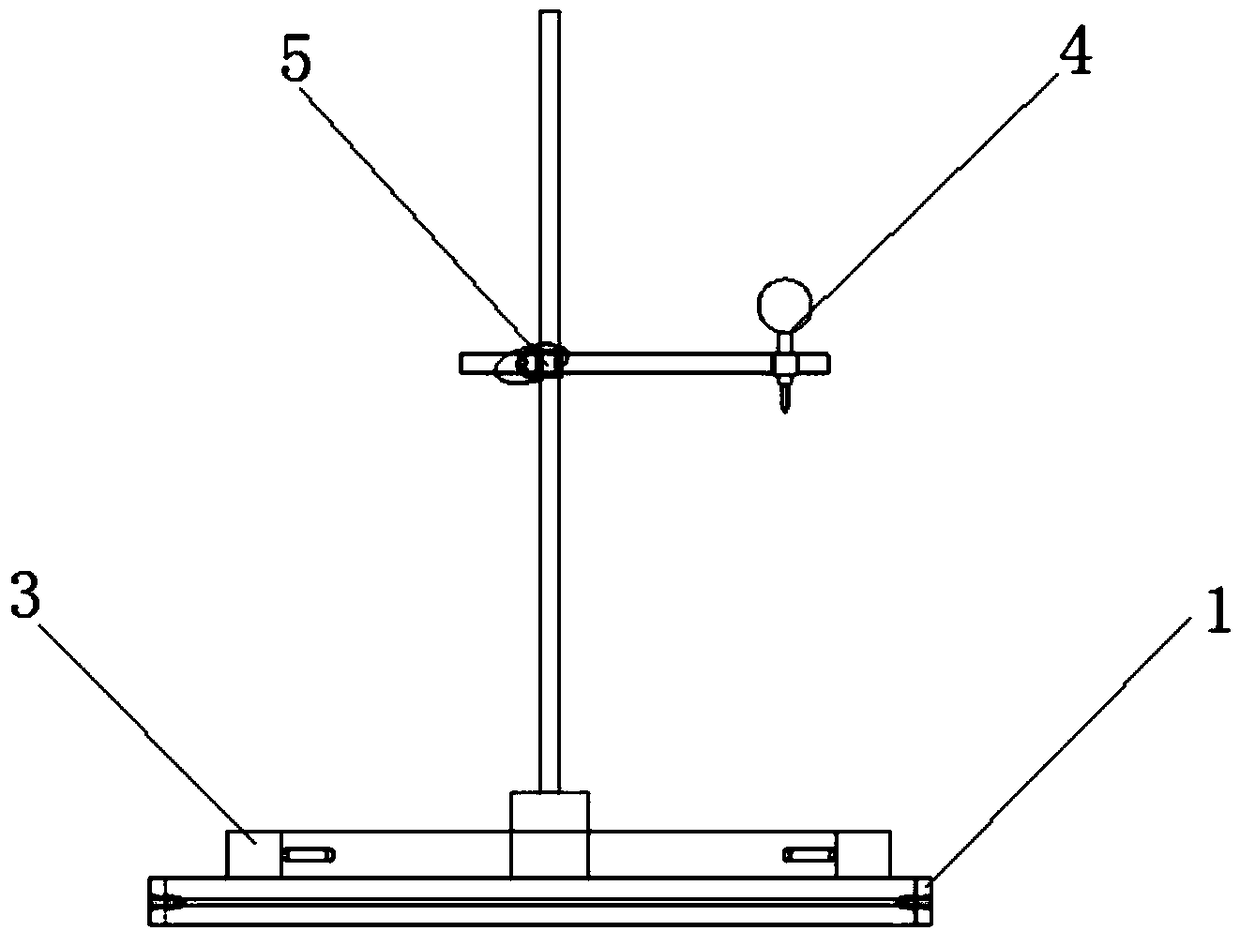

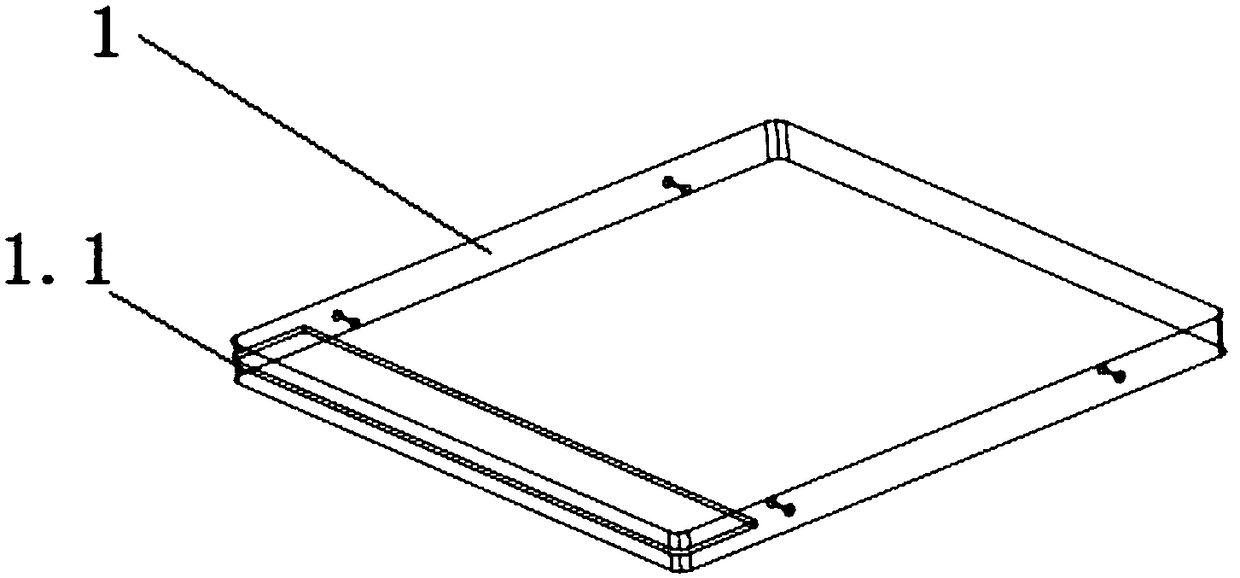

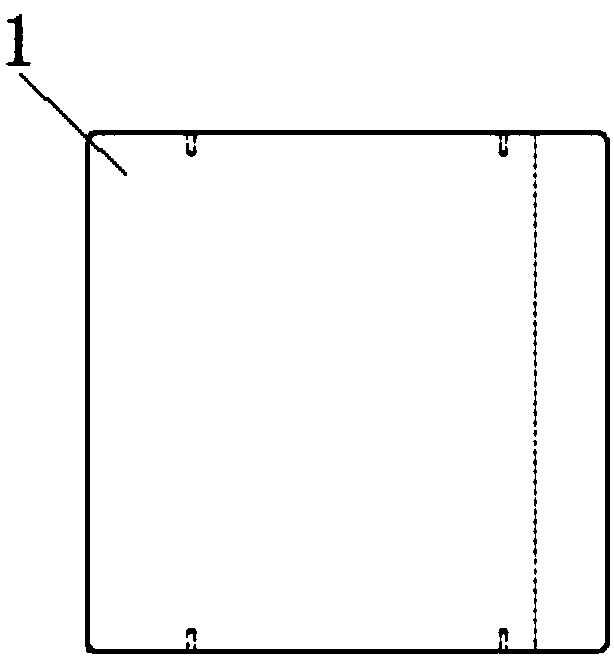

[0043] Such as Figures 1 to 8The wafer adapter verification repair tool shown includes a straightening table 1 , an identification aligner 2 , a top plane correction table 3 and a plane inspection instrument 4 . The correction table 1 is provided with a wafer correction groove 1.1, and the correction table 1 also provides a standard plane for the wafer adapter and the identification aligner 2, the top plane correction table 3 and the plane inspection instrument 4, and the top plane correction table When 3 is set on the correction table 1, the top plane correction table 3 also provides a standard plane for the wafer adapter. The correction table 1 provides a standard plane, which is processed by finishing. The surface of the standard plane of the correction table 1 is level, and the level difference of each point on the surface is <0.01mm. If there is no repair or the measurement error is large, the error cannot be strictly controlled, so the correction platform 1 is not only...

Embodiment 2

[0045] Such as Figures 1 to 8 As shown, the wafer adapter verification repair tool includes a correction station 1 , an identification aligner 2 , a top plane correction station 3 and a plane inspection instrument 4 . The correction table 1 is provided with a wafer correction groove 1.1, and the correction table 1 also provides a standard plane for the wafer adapter and the identification aligner 2, the top plane correction table 3 and the plane inspection instrument 4, such as Figure 5 and 6 , when the top plane correction table 3 is set on the correction table 1, the top plane correction table 3 also provides a standard plane for the wafer adapter. The correction table 1 provides a standard plane, which is processed by finishing. The surface of the standard plane of the correction table 1 is level, and the level difference of each point on the surface is figure 2 , 3 And 4, the straightening table 1 is made of steel, and its upper surface is a standard plane, and the wa...

Embodiment 3

[0047] The method for verifying and repairing the wafer adapter is characterized by comprising: a step of disassembling the wafer adapter, a step of component verification, a step of rectification, a step of repair verification and a step of assembling the wafer adapter.

[0048] The part verification step, by direct observation to determine the location of the obvious deformation on the wafer adapter part, the wafer adapter is placed on the standard plane of the correction table 1, using the identification aligner 2, the top plane correction table 3 and the plane inspection Instrument 4 checks to determine the slight deformation position of the wafer adapter; uses the correction groove 1.1 of the correction table 1 to verify whether the wafer adapter is used to connect with the machine to determine whether it is deformed.

[0049] In the correcting step, a mechanical deformation method is used to correct and repair the confirmed deformed positions on the wafer adapter part and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com