Cable bridge end structure and construction method for cable bridge to pass through fire compartment

A cable tray and construction method technology, applied in the direction of electrical components, etc., can solve problems such as inability to install, unattractive visual effects, and difficulty in filling and blocking completely with fireproof materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

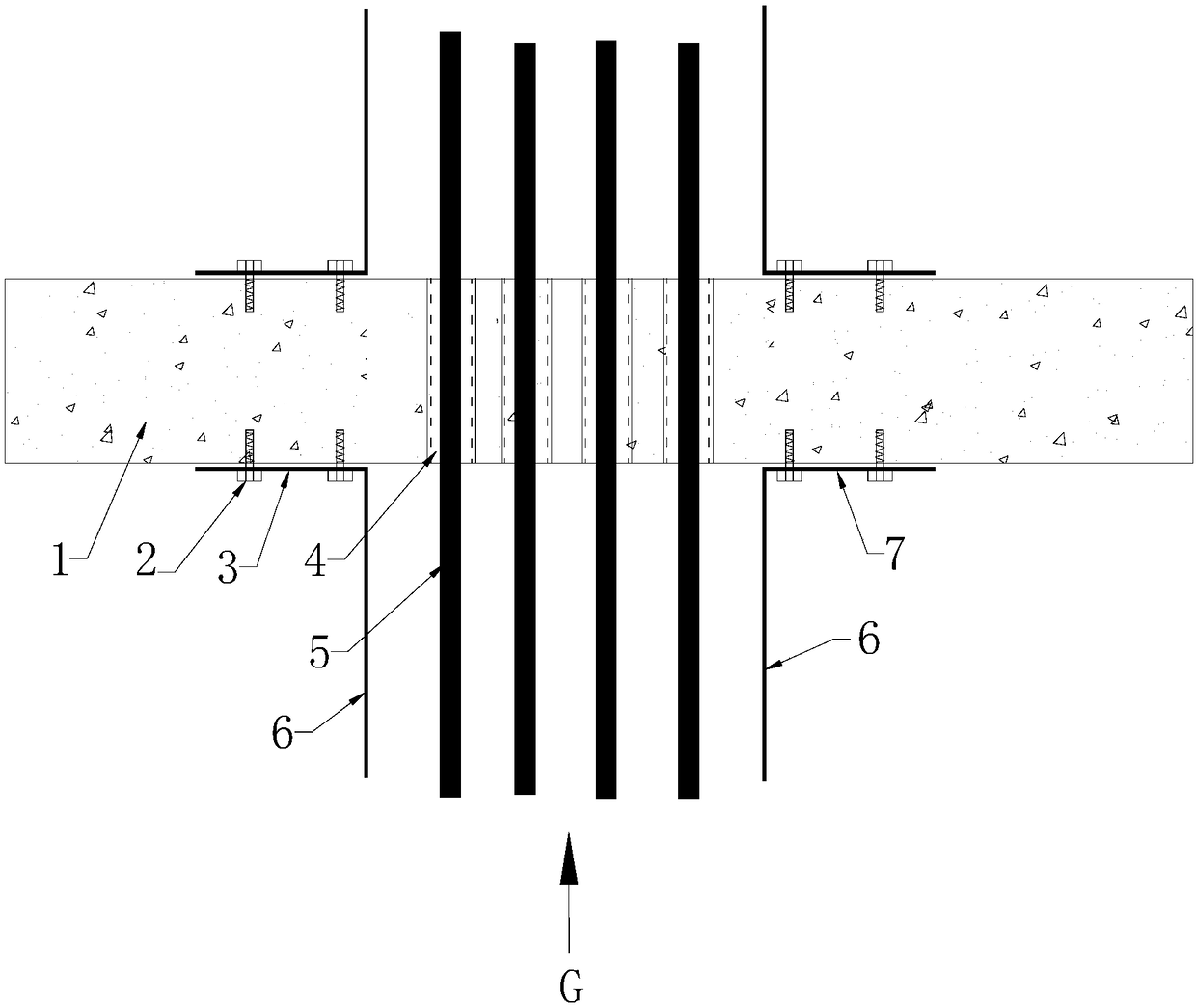

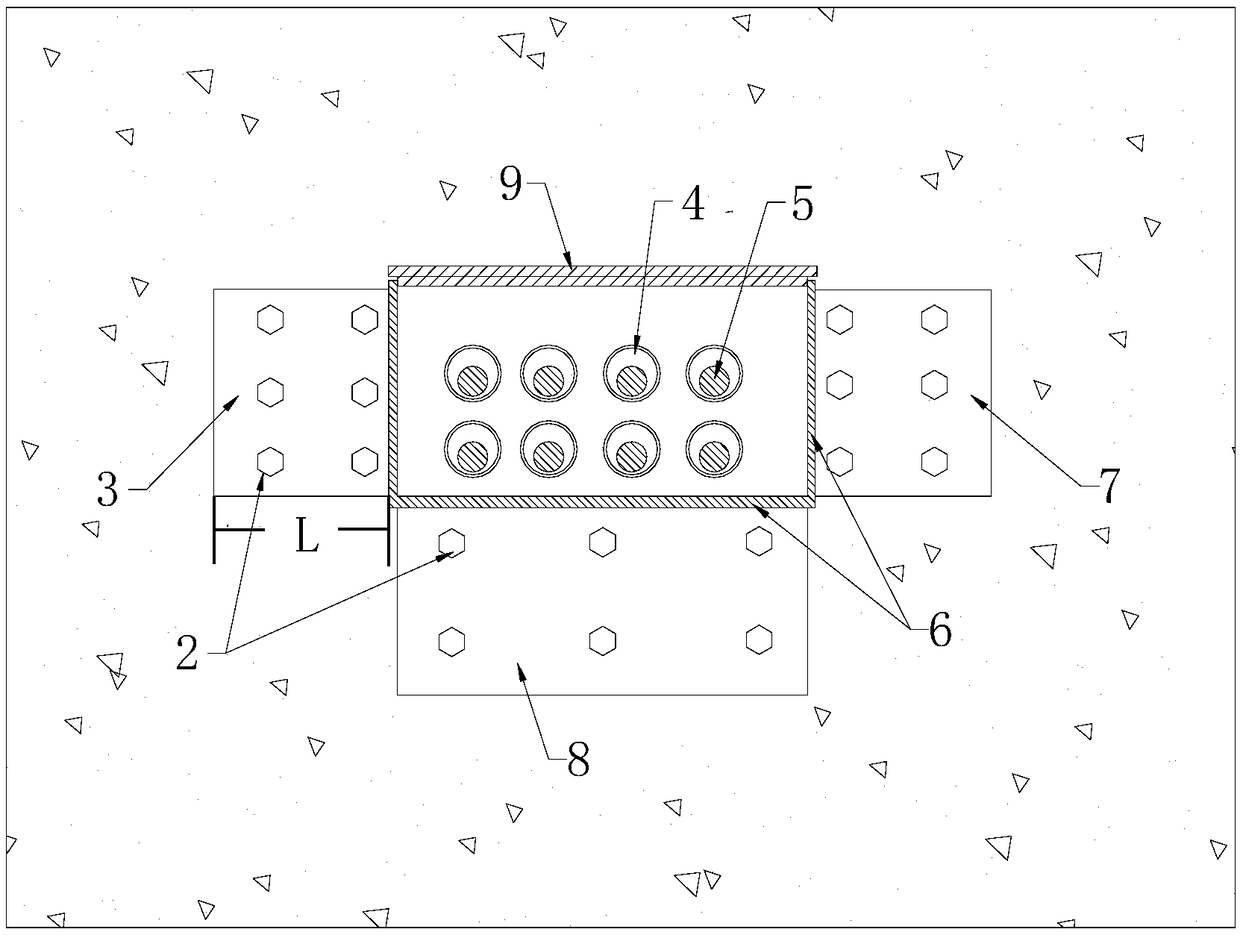

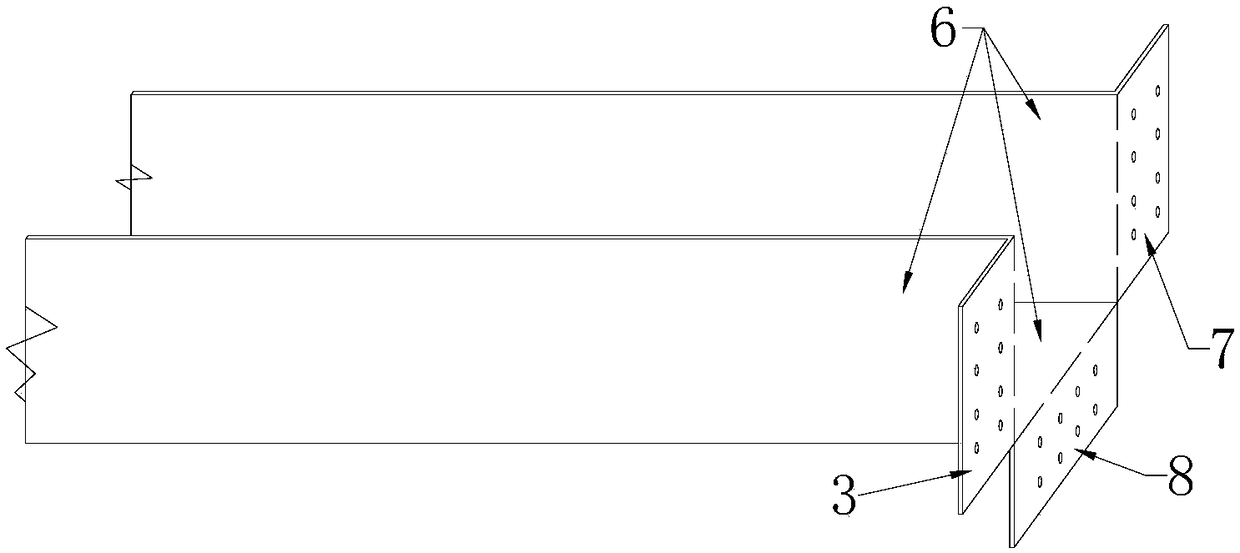

[0025] Below the present invention is described in detail: as Figure 1-5 The cable tray shown in the above includes a concave-shaped bridge frame made of three baffles 6, and the design structure of the connecting end is improved, specifically: the ends of the baffles 6 on the three sides of the bridge are provided with valgus ends, and the valgus The ends form the left end face 3, the right end face 7, the lower end face 8 with respect to the angle of 90 degrees of the respective main faces, and the left end face 3, the right end face 7, the lower end face 8 are respectively provided with some installation holes.

[0026] In the original construction method, the end of the bridge frame is directly against the wall 1, the port is set on the embedded steel pipe 4, and then the contact points are fixed and sealed. The construction is to coat the inner and outer sides of the bridge frame respectively. Sufficient quantity of fireproofing material10. But because the bridge frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com