Automated hermetia illucens culturing device

A black soldier fly and linkage technology, applied in the direction of non-electric variable control, simultaneous control of multiple variables, instruments, etc., can solve the problems of inability to realize continuous breeding, large labor consumption, low degree of automation, etc., and achieve high-efficiency continuous breeding, The effect of large space utilization and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0024] Now in conjunction with the accompanying drawings, a kind of automatic black soldier fly breeding device designed by the present invention is further explained. The content in the claims of the present invention is not limited in any form, and all kinds of designs derived from the creations of the present invention shall be protected by the present invention.

[0025] The orientation nouns such as "up, down, left, and right" in this embodiment are only used to indicate the position of each component in the description of the drawings, and do not limit the position of its actual application.

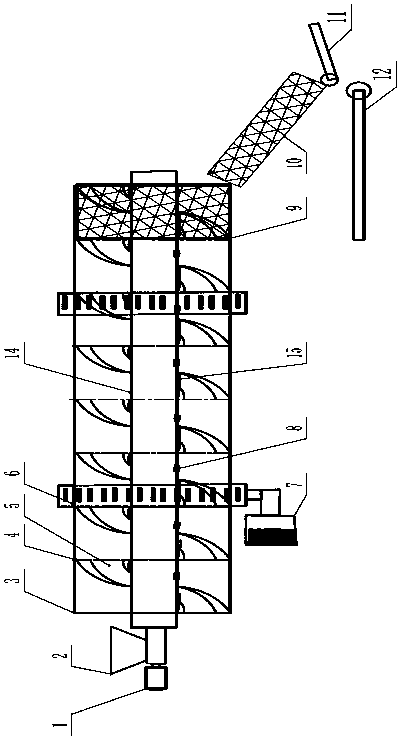

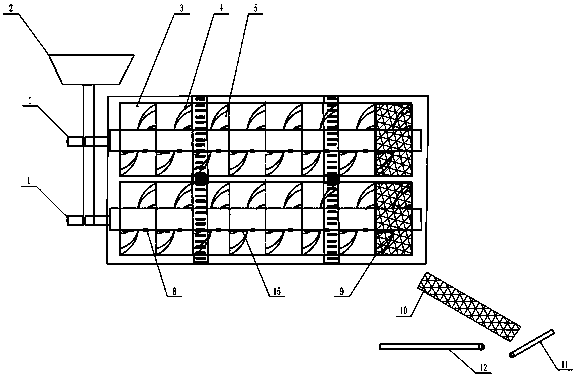

[0026] combine figure 1 , an automatic black soldier fly breeding device, the basic components include a breeding pipe body 3, a feeding pipe 14, a motor 7 and a vibrating trommel 10.

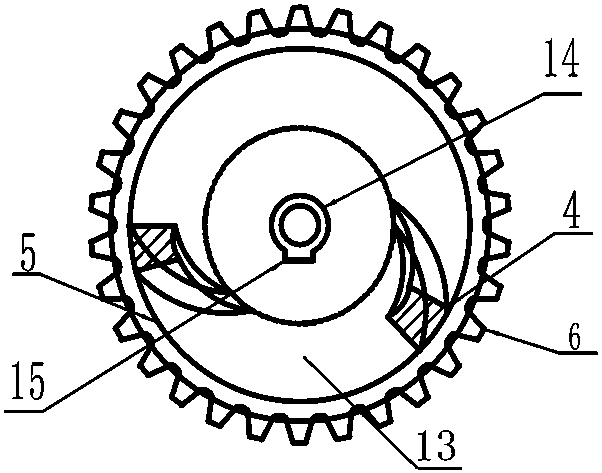

[0027] The outer wall of the culture pipe body 3 is provided with 2-3 linkage gears 6, one of which is directly connected with the motor 7 for driving the rotation of the culture pipe body 3. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com