Suitcase zipper and suitcase

A suitcase and zipper technology, which is applied in the field of zippers for suitcases and suitcases, can solve the problems of unsmooth pulling, zipper jamming, and inconvenience for people, so as to avoid jamming or jamming, prevent jamming, and facilitate processing and production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

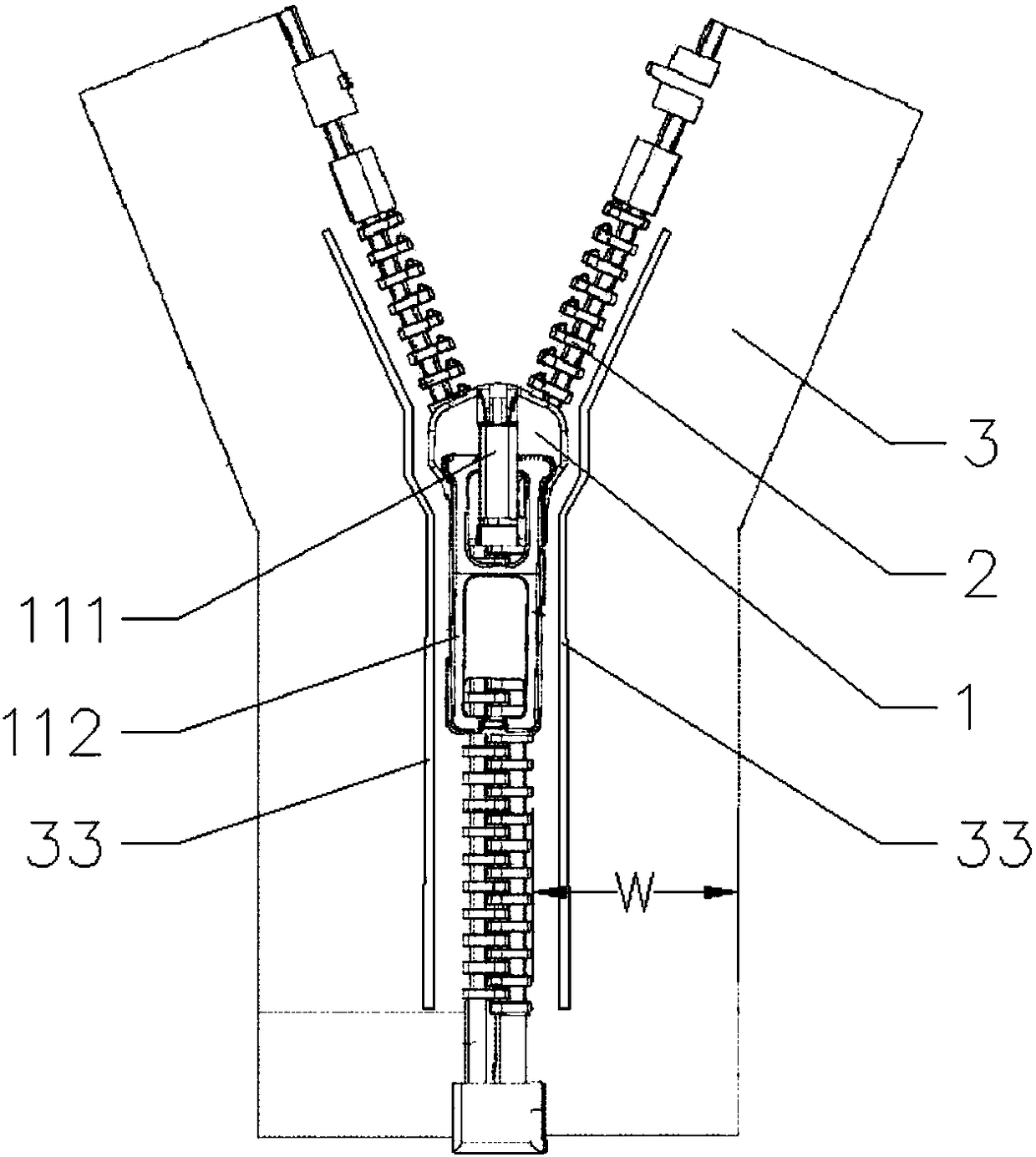

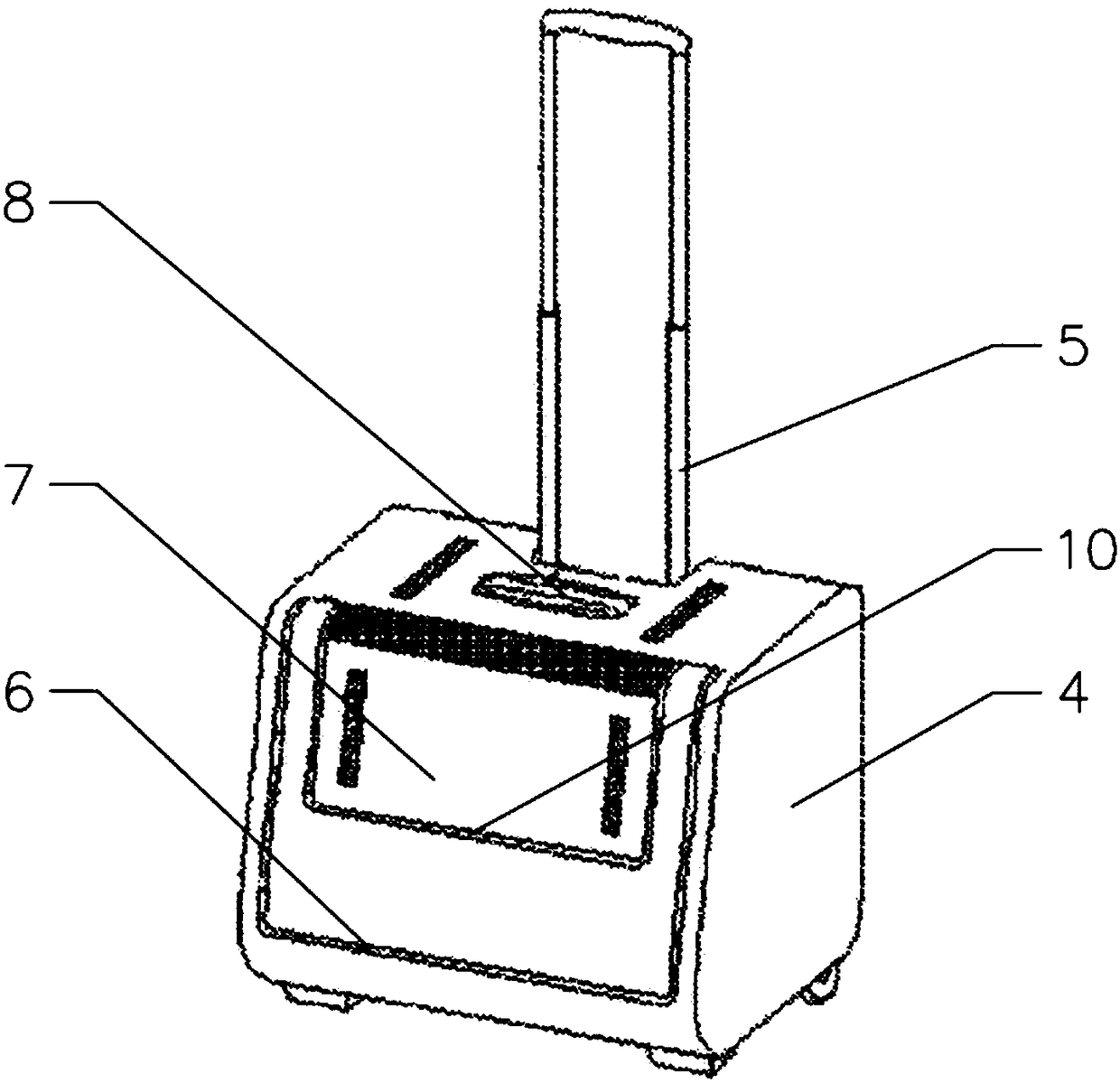

[0027] Such as Figures 1 to 2 As shown, the present invention provides a zipper for a suitcase, comprising a slider 1, a chain tooth 2 and a chain belt 3, the chain belt 3 is a cloth belt and is formed by two cloth belts, which facilitates the processing and molding of the chain belt and improves production efficiency , the sprocket 2 is provided with multiple and evenly spaced, and two rows of sprocket 2 are formed on the inner edge of the two cloth belts. The slider 1 is installed between the two rows of sprocket 2, and the slider 1 is pulled to make the two rows The sprocket 2 is engaged or separated to realize the opening and closing of the zipper.

[0028] The width of the two tapes is equal, of course, it may not be equal, and the width of a single tape is W, 5mm≤W≤30mm, in this embodiment, W is specifically 18mm, so that the zipper can be well sewn to the box On the surface, the zipper is fixed reliably, and the zipper will not fall off from the box when the zipper is...

Embodiment 2

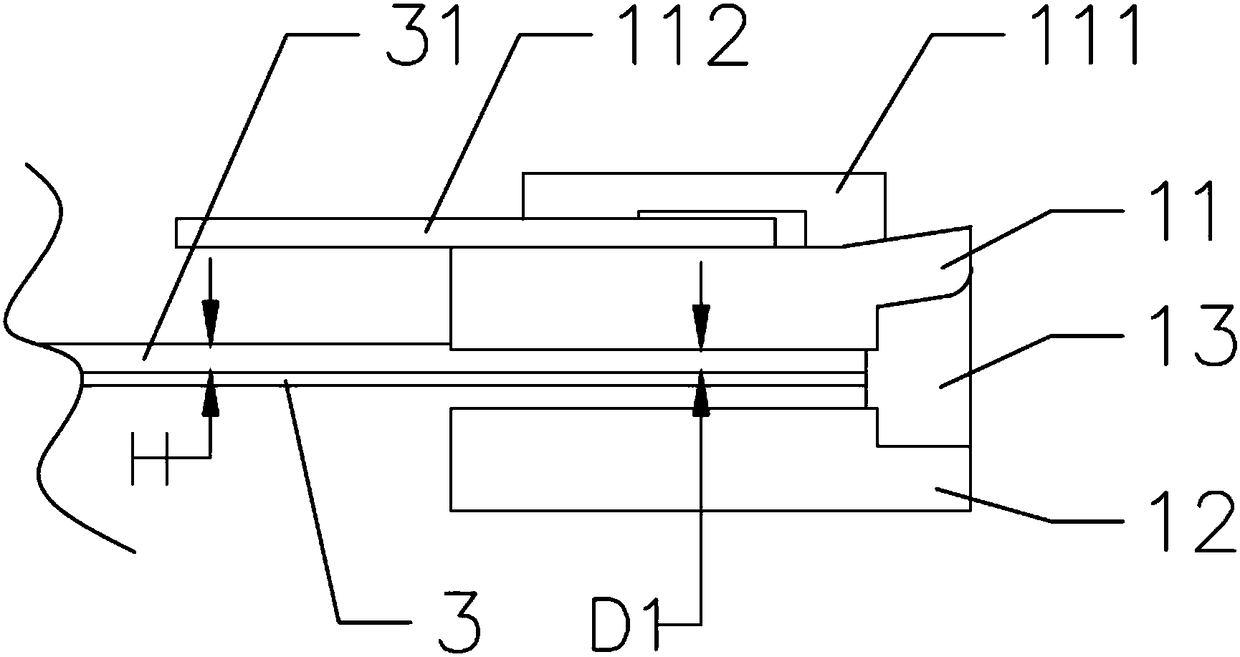

[0039] The difference between this embodiment and the first embodiment is that a blocking portion is also provided on the lower surface of the chain belt.

[0040] In this example, if Figure 4 As shown, the lower surface of the chain belt 3 is also provided with a blocking portion 31, the blocking portion 31 is located on both sides of the sliding seat 12, the gap between the lower end surface of the sliding seat 12 and the lower surface of the chain belt 3 is D2, and H is greater than D2 , Of course, H can also be equal to D2.

[0041] The advantage of this embodiment is that the blocking part is set on the lower surface of the chain belt, which further prevents the lining from entering the gap between the lower surface of the chain belt and the lower end surface of the sliding seat, and further prevents the zipper from being stuck or stuck. And it is located on both sides of the sliding seat, so that the gaps on both sides of the slider are closed, which can better prevent...

Embodiment 3

[0043] The difference between this embodiment and the first and second embodiments is that the blocking part is different.

[0044] In this embodiment, the blocking portion is a rib arranged on the surface of the chain belt, and the rib is a plastic rib, of course, it can also be a metal rib, and the rib is fixed on the surface of the chain belt by pasting.

[0045] The advantage of this embodiment is that the blocking portion is a rib located on the surface of the chain belt, the rib is a plastic rib or a metal rib, and the plastic rib or metal rib is fixed on the surface of the chain belt by pasting, To prevent the lining from entering the gap, it cannot effectively prevent the lining from entering the gap, and has a simple structure, is easy to realize, and is convenient for processing and forming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com