Centrifugal rotation type granulation drying device

A technology of centrifugal rotation and drying device, which is applied in the direction of liquid separation into beads, granulation, spray evaporation, etc. It can solve the problems that the product granulation and particle size requirements cannot be met, cannot be processed in large quantities, and the drying method is single, and achieve good economic benefits. And use value, low cost, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

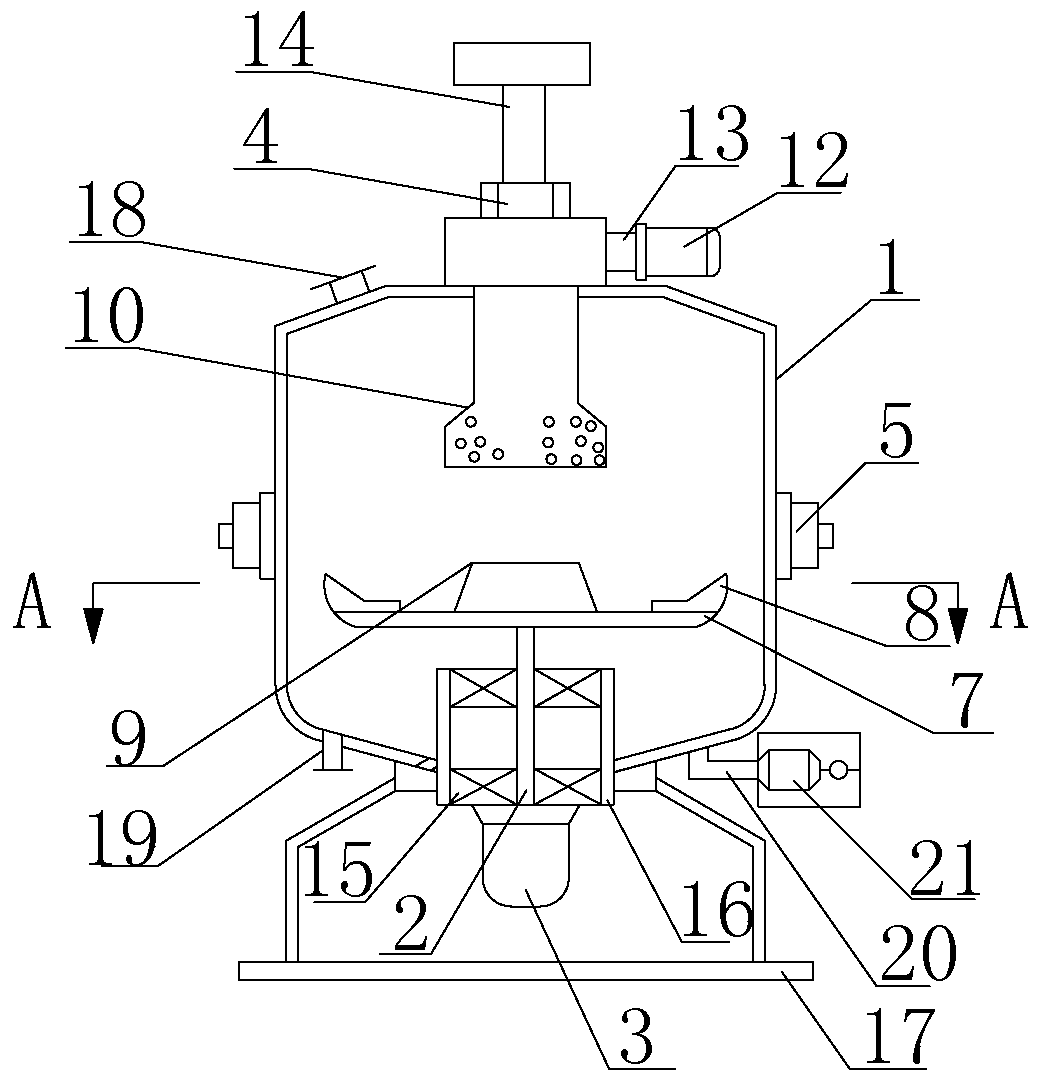

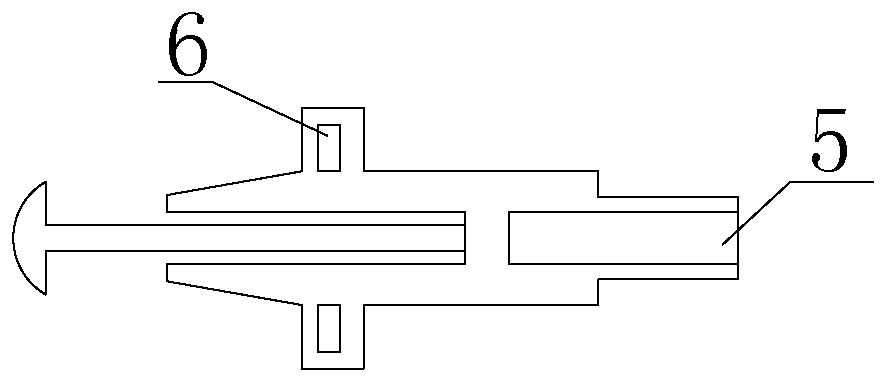

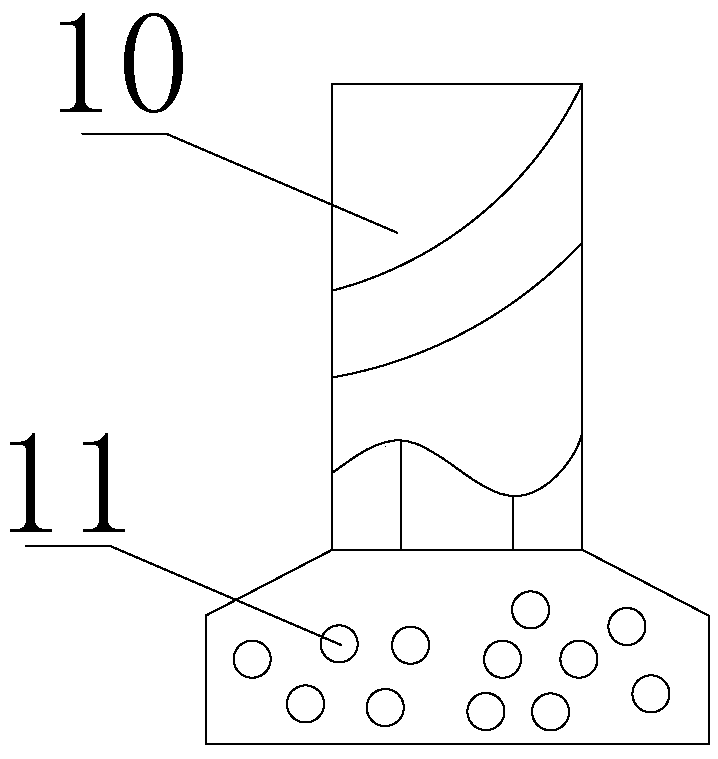

[0017] Such as Figure 1~Figure 5 As shown, the present invention includes a circular housing 1, the rotating shaft 2 passes through the housing 1 and is connected with the pulverizing mechanism in the housing 1, the outer lead-out end of the rotating shaft 2 is connected to the motor 3, and the housing 1 is provided with a feeding port, Outlet, hot air pipe 4 is arranged on the housing 1 above the crushing mechanism, and the hot air pipe 4 is connected to the screw lifter. A sonic spray head 5 is symmetrically installed in the middle of the housing 1, and the spray port 6 of the sonic spray head 5 is connected to the feed port. Micronization.

[0018] The crushing mechanism includes a crushing disc 7 connected to the rotating shaft 2, the crushing disc 7 is bowl-shaped, and 6 pulverizing knives 8 are arranged on the outer edge of the upper surface of the pulverizing disc 7. Folding, the center of the crushing disc 7 is provided with a protrusion 9; the crushing disc 7 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com