Carriage support unit and Robot carriage

A technology of supporting unit and robot, applied in the direction of manipulator, mechanical equipment, components with teeth, etc., can solve the problems of no assembly error absorption function, increase of regular management cost, accelerated curing, etc., to achieve longer maintenance cycle and reduce maintenance. The effect of improving cost and ease of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

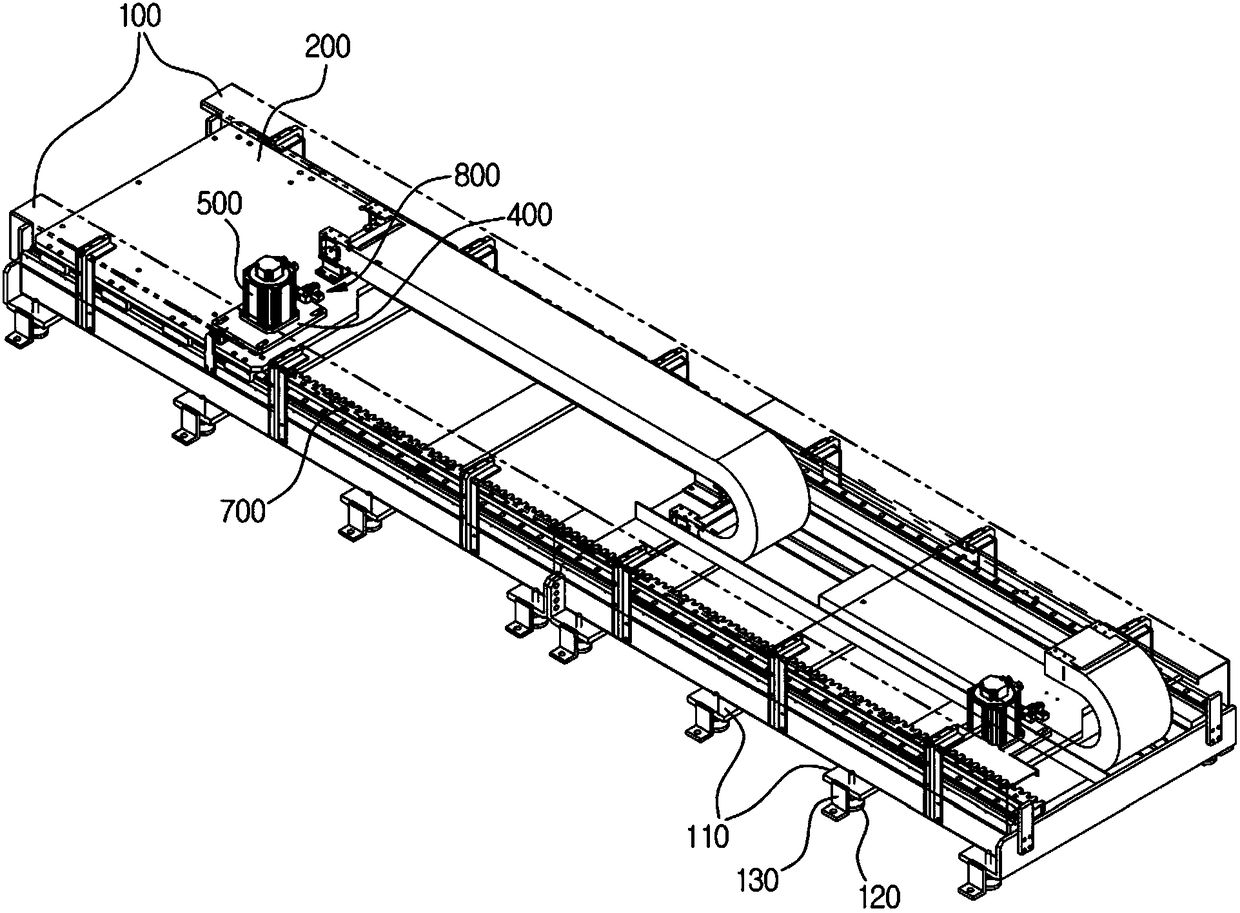

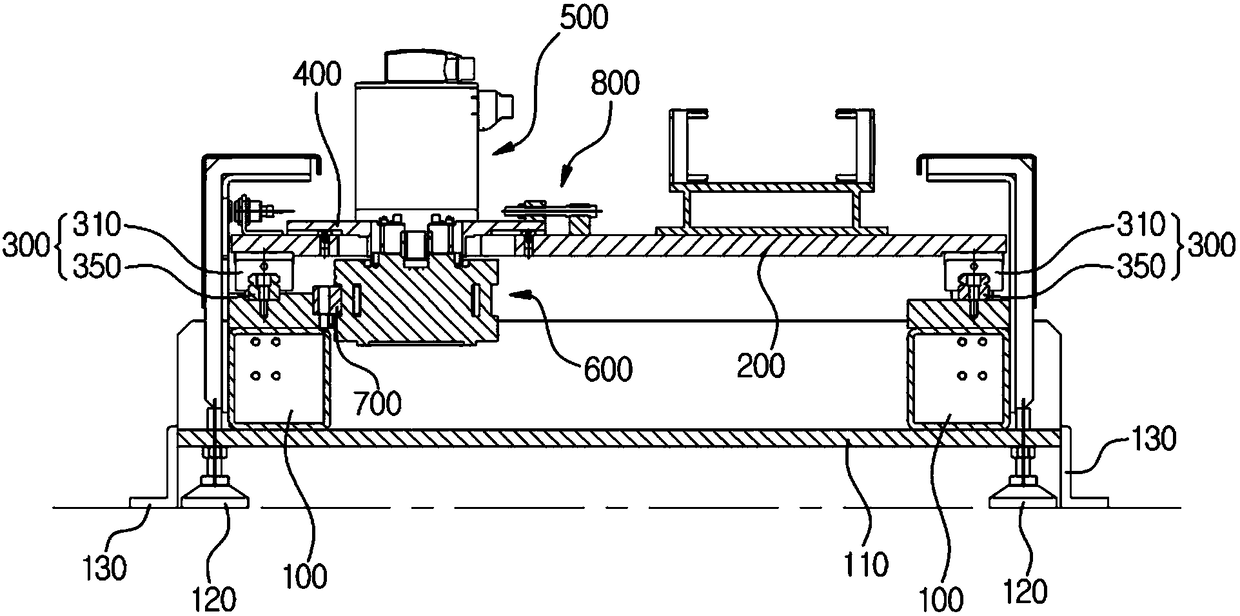

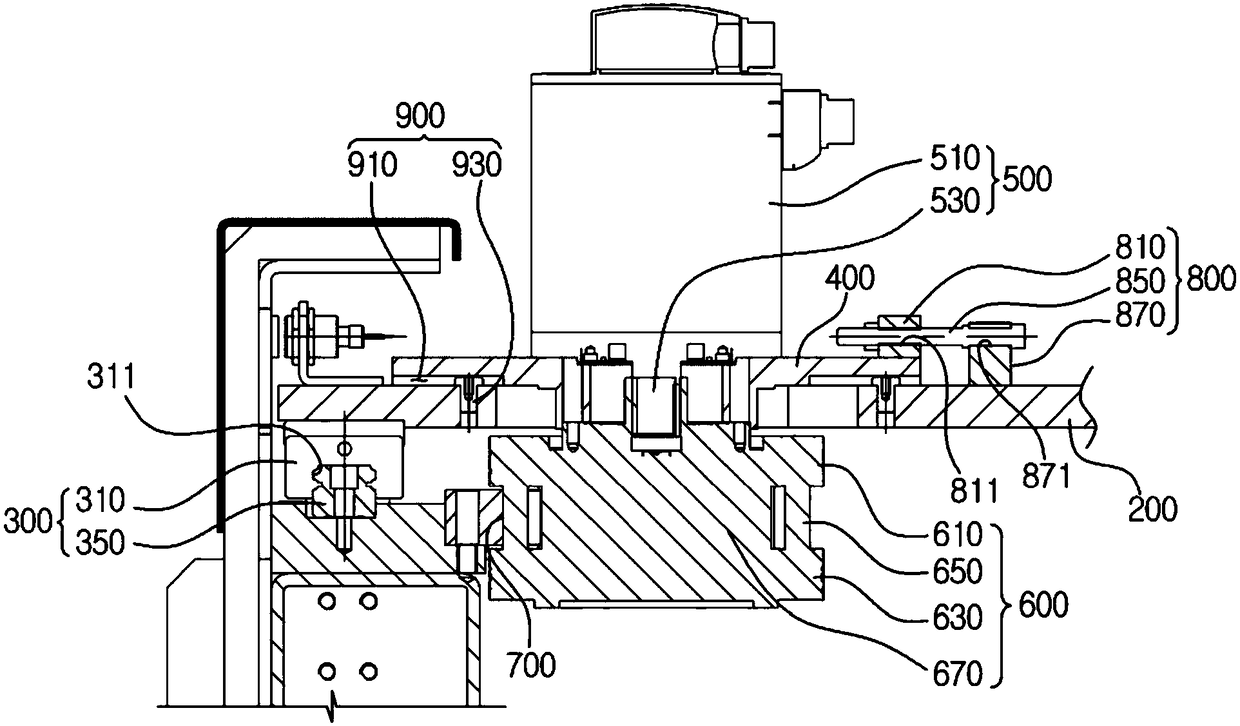

[0032] Preferred exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Before that, it should be understood that the terms and words used in the specification and claims should not be construed as being limited to the meanings in the general and dictionaries, but should be interpreted as corresponding to the technical aspects of the present invention based on the following principle Corresponding meanings and concepts, the principle is that in order to best describe their inventions, inventors can define terms appropriately.

[0033] Therefore, the exemplary embodiments described herein and the configurations shown in the drawings are only the most preferred embodiments of the present invention, and since they do not represent the entire content of the technical essence of the present invention, it should be understood that In its application, there may be various equivalents and modifications which may be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com