Automatic wood board conveying device

A technology for conveying equipment and boards, applied in conveyors, mechanical equipment, conveyor objects, etc., can solve the problems of increased procurement costs, inability to adjust, high maintenance costs, etc., to reduce unnecessary expenses, reduce labor input, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

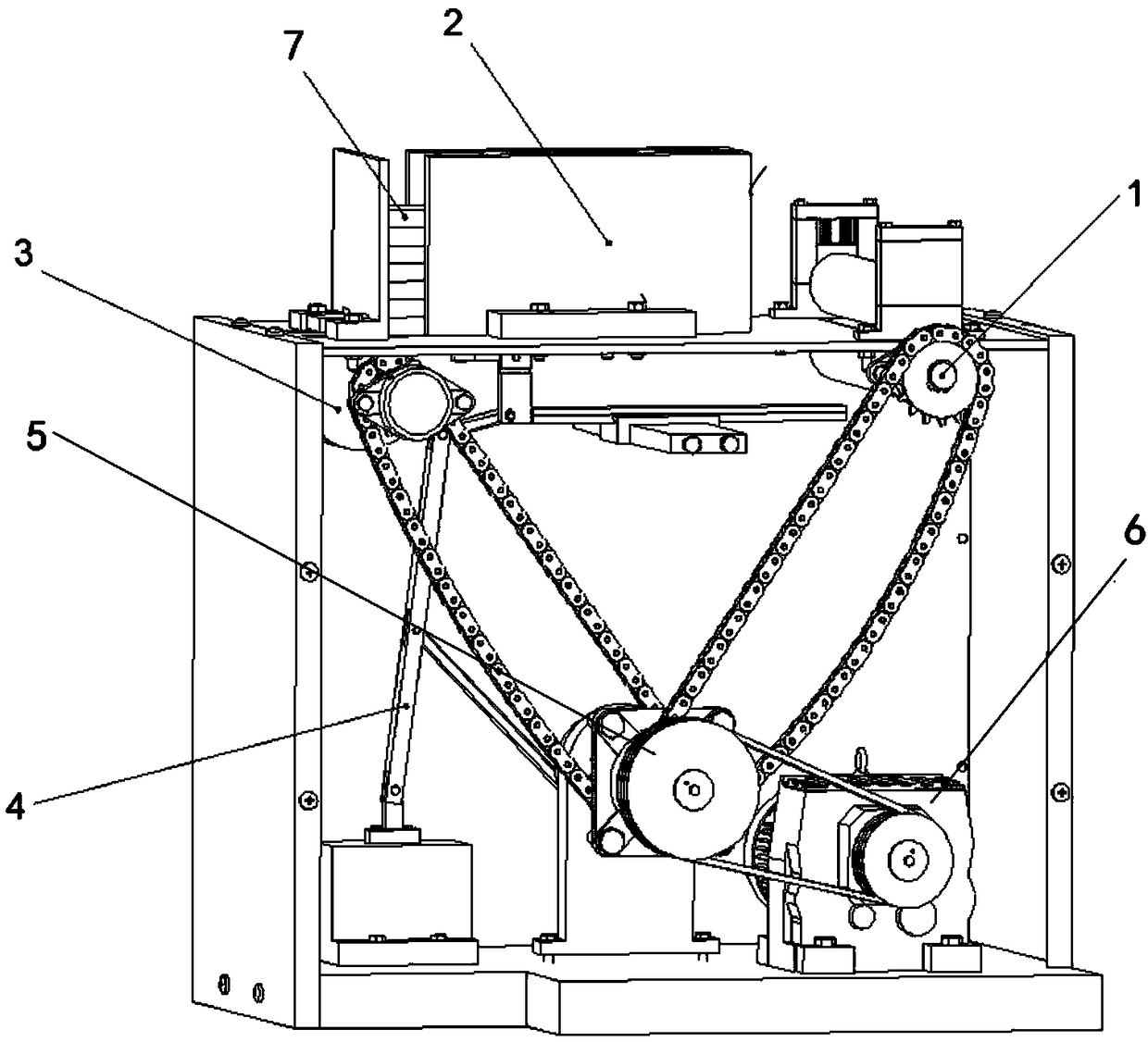

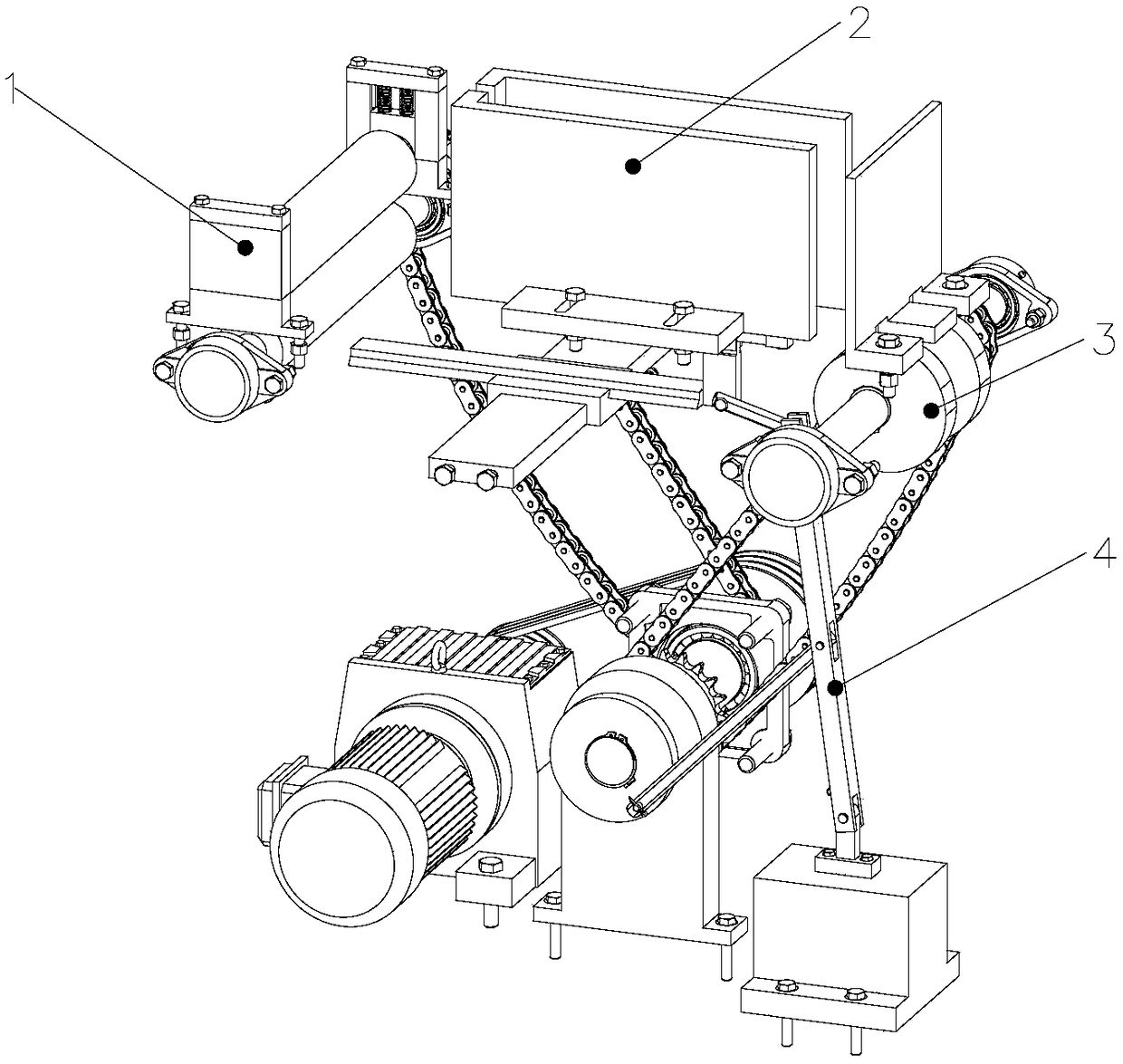

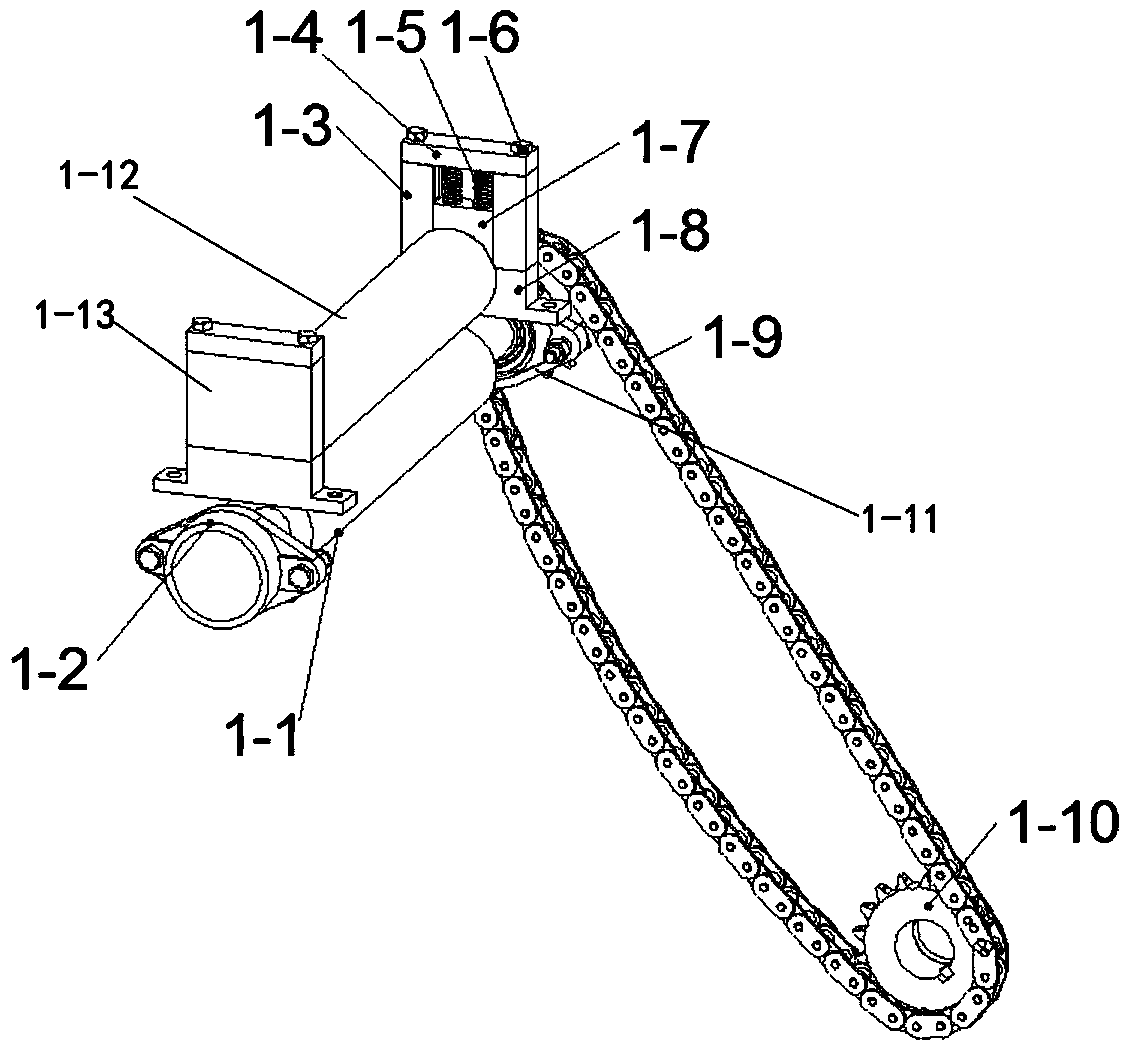

[0021] like Figure 1-2 As shown, an automatic wood board conveying equipment includes a frame, a wood board conveying mechanism 1, a wood board accommodating mechanism 2, a wood board jacking mechanism 3, a wood board pushing mechanism 4, a transmission mechanism 5 and a power mechanism 6, and the power mechanism 6 and the transmission mechanism 5 Connected, many stacks of wooden boards are placed in the wooden board accommodating mechanism 2, the wooden board accommodating mechanism 2 is located on the upper rack, the board conveying mechanism 1 is located in front of the upper rack and the wooden board accommodating mechanism 2, and the board pushing mechanism 4 and the wooden board are jacked up. The mechanism 3 is located in the frame respectively, below the wood board accommodating mechanism 2, the transmission mechanism 5 and the power mechanism 6 are located on the bottom frame, the wood board conveying mechanism 1, the wood board jacking mechanism 3 and the wood board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com