Novel fully prefabricated track structure used for tunnel in railway track field

A prefabricated assembly and railway track technology, applied in the direction of track, road, ballast layer, etc., can solve the problems of low degree of factory prefabrication, complex composition of track structure, and difficulty in on-site implementation, so as to facilitate maintenance and replacement of parts , easy to disassemble, and good maintenance and repair conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

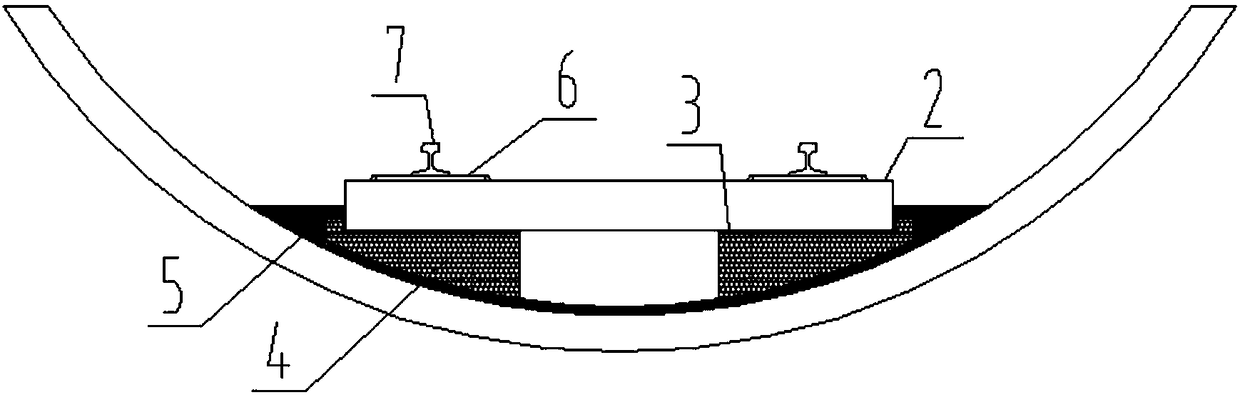

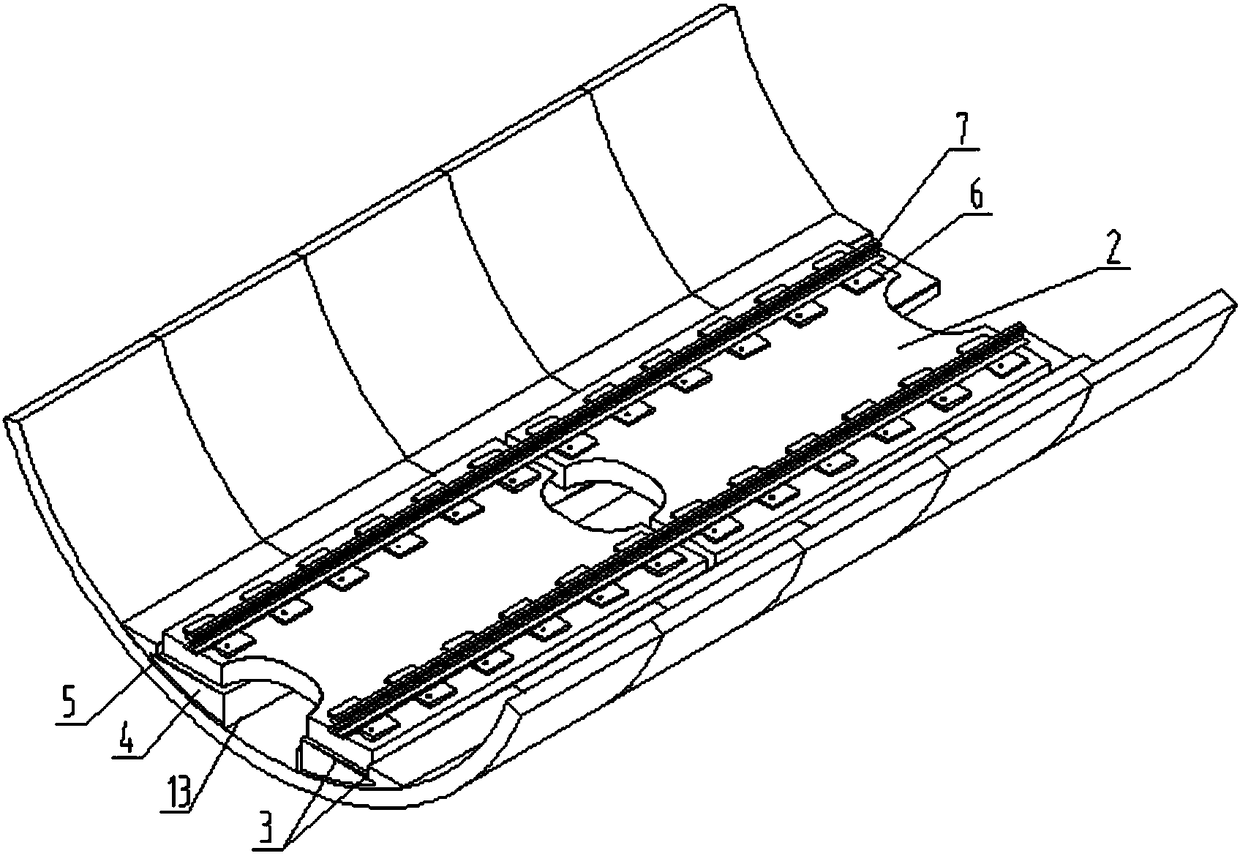

[0046] Such as figure 1 As shown, the fully prefabricated assembled track structure 1 of the present invention comprises a track plate 2 laid from top to bottom, an elastic mold cushion layer 3, a prefabricated assembly block 4 and an adjustment layer 5, and a rail 7 is laid on the track plate 2, and the adjustment layer 5 Laying on the shield segment, the prefabricated assembly block 4 is laid between the adjustment layer 5 and the track plate 2 and laid along the rail 7, and the bottom surface of the track plate 2 is supported by the elastic mold cushion layer 3 and laid on the prefabricated assembly block 4.

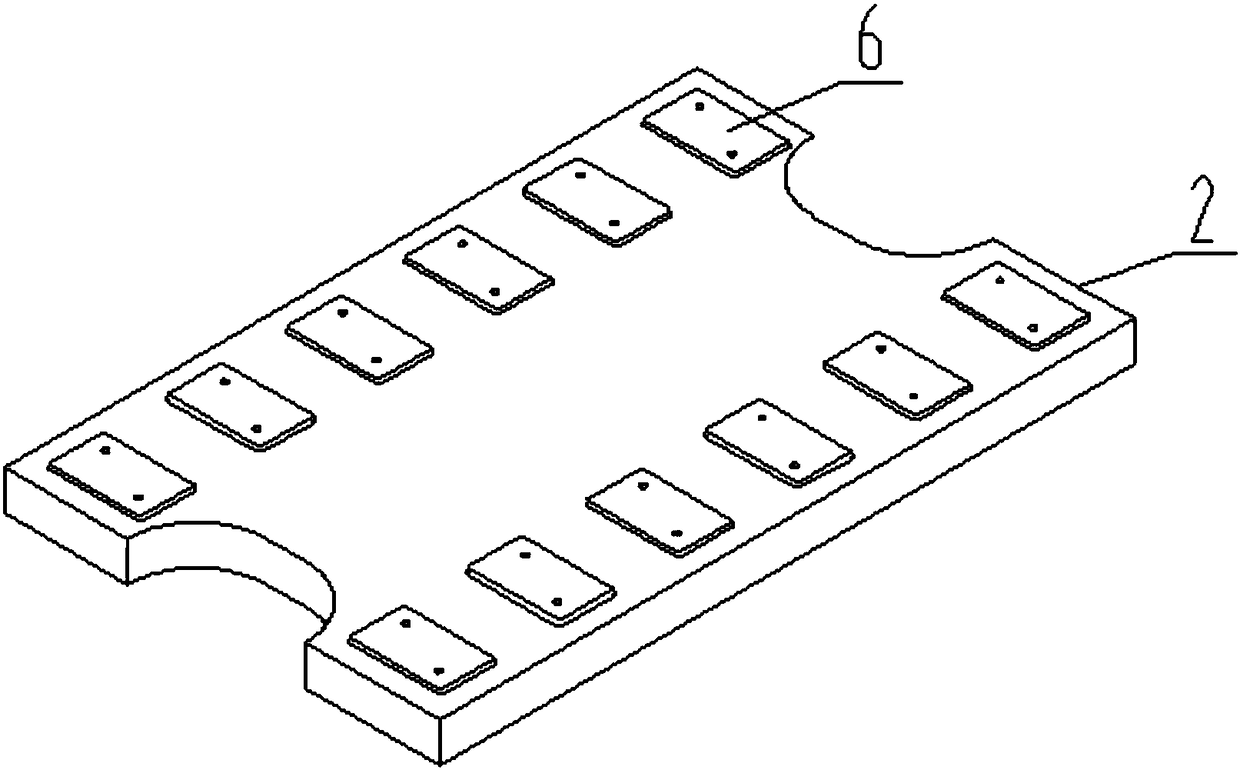

[0047] The track slab 2 adopts ordinary prefabricated slabs, hollow frame slabs, ladder-shaped longitudinal beams or H-shaped sleepers and other structures, and is equipped with prefabricated rail bearing platforms, reserved fastener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com